Method for preparing titanium subgroup carbonitride solid solution composite ceramic material by sintering

A technology of carbonitride and multi-phase ceramics, which is applied in the field of multi-phase ceramic materials, can solve the problems of poor sintering and fracture toughness of multi-phase ceramics, improve sintering compactness, improve preparation performance, and reduce cumbersome experimental steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A kind of sintering method of the present embodiment prepares the method for titanium subgroup carbonitride solid solution multiphase ceramic material to carry out as follows:

[0041] Step 1: Mix 95% zirconium carbide powder (1 μm ~ 3 μm) and 5% titanium carbonitride powder (1 μm ~ 3 μm) according to mole percentage, first disperse ultrasonically at 35 kHz for 10 minutes, and then ball mill and mix under the protection of inert gas Material, the grinding ball is cemented carbide, the ball-to-material ratio is 40:1, the ball milling speed is 250rpm, the ball milling time is 24h, and the mixed powder is obtained after passing through a 200 mesh sieve;

[0042] Step 2: The mixed powder obtained in step 1 is subjected to hot pressing and sintering. First, the temperature is raised to 600°C at a heating rate of 30°C / min, then to 2000°C at a heating rate of 20°C / min, and kept at 2000°C 1h, then lower to room temperature at a rate of 20°C / min, pressurize when th...

Embodiment 2

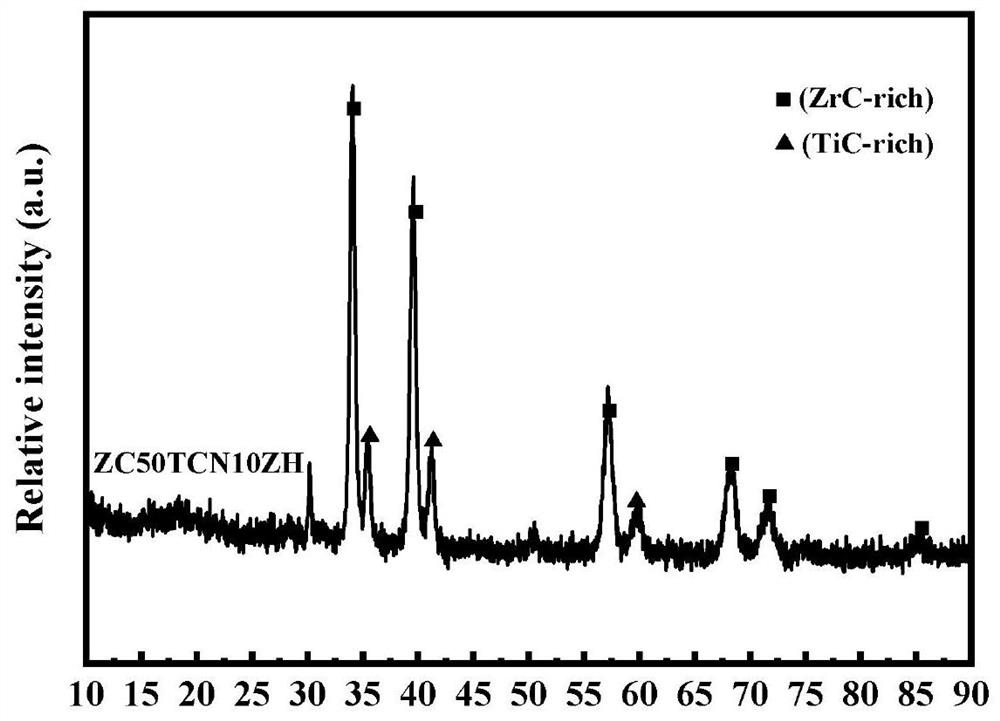

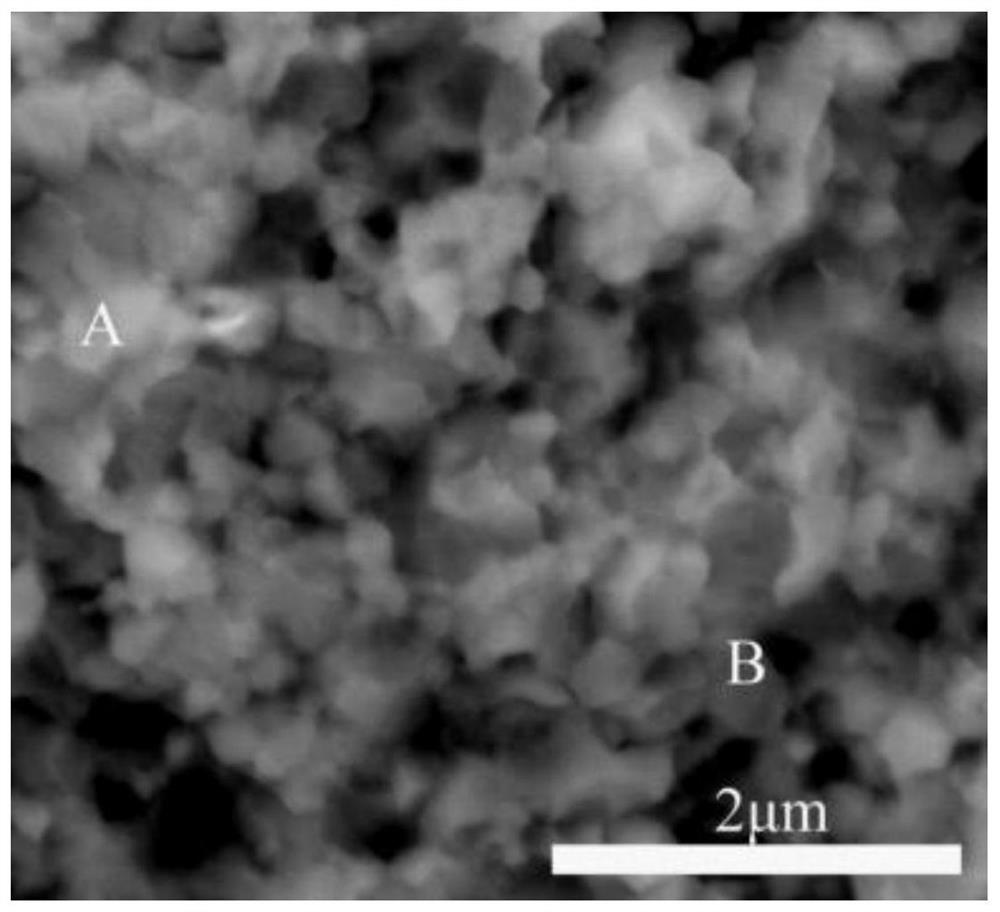

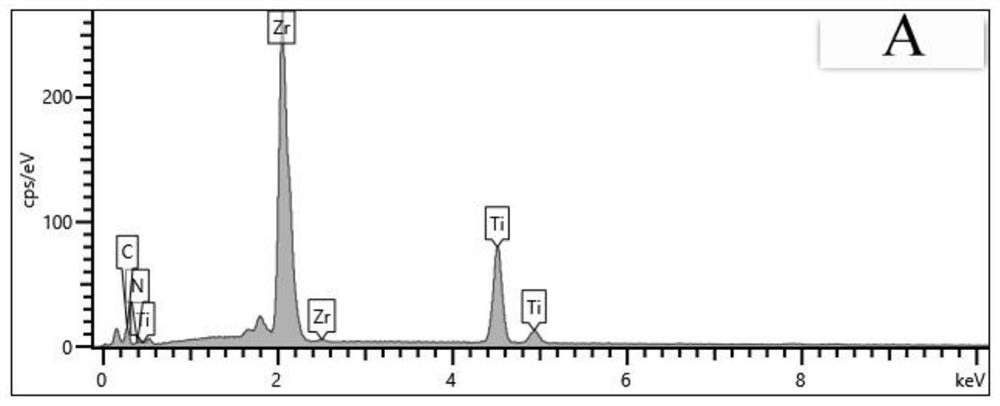

[0043] Embodiment 2: A kind of sintering method of the present embodiment prepares the method for titanium subgroup carbonitride solid solution multiphase ceramic material to carry out as follows:

[0044] Step 1: Mix 90% zirconium carbide powder (1 μm ~ 3 μm) and 10% titanium carbonitride powder (1 μm ~ 3 μm) according to mole percentage, first disperse ultrasonically at 35 kHz for 10 minutes, and then ball mill and mix under the protection of inert gas Material, the grinding ball is cemented carbide, the ball-to-material ratio is 40:1, the ball milling speed is 250rpm, the ball milling time is 24h, and the mixed powder is obtained after passing through a 200 mesh sieve;

[0045] Step 2: The mixed powder obtained in step 1 is subjected to hot pressing and sintering. First, the temperature is raised to 600°C at a heating rate of 30°C / min, then to 2000°C at a heating rate of 20°C / min, and kept at 2000°C 1h, then lower to room temperature at a rate of 20°C / min, pressurize when t...

Embodiment 3

[0046] Embodiment 3: A kind of sintering method of this embodiment prepares the method for titanium subgroup carbonitride solid solution multiphase ceramic material to carry out according to the following steps:

[0047] Step 1: Mix 80% zirconium carbide powder (1 μm ~ 3 μm) and 20% titanium carbonitride powder (1 μm ~ 3 μm) according to mole percentage, first disperse ultrasonically at 35 kHz for 10 minutes, and then ball mill and mix under the protection of inert gas Material, the grinding ball is cemented carbide, the ball-to-material ratio is 40:1, the ball milling speed is 250rpm, the ball milling time is 24h, and the mixed powder is obtained after passing through a 200 mesh sieve;

[0048] Step 2: The mixed powder obtained in step 1 is subjected to hot pressing and sintering. First, the temperature is raised to 600°C at a heating rate of 30°C / min, then to 2000°C at a heating rate of 20°C / min, and kept at 2000°C 1h, then lower to room temperature at a rate of 20°C / min, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com