High-elasticity anti-radiation nanofiber aerogel material and preparation method thereof

A technology of nanofibers and nanofiber membranes, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc. It can solve the problems of insufficient heat insulation performance, poor radiation resistance performance, large thermal conductivity, etc., and achieve excellent radiation resistance Features, good high temperature insulation performance, good radiation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

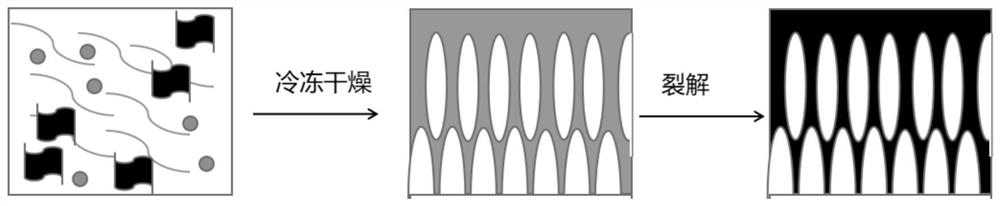

[0034] The present invention provides a kind of preparation method of highly elastic anti-radiation nanofiber airgel material in the first aspect, described method comprises the following steps:

[0035] (1) Tetraethyl orthosilicate (TEOS), phosphoric acid (H 3 PO 4 ) and water (such as deionized water) are uniformly mixed to obtain a mixed solution, and then the mixed solution is stirred for 1 to 24 hours (such as 1, 6, 12 or 24 hours) to obtain a hydrolyzate, and then titanium dioxide is added to the hydrolyzate Nano-powder and continue to stir for 1-12 hours (such as 1, 3, 6, 8, 10 or 12 hours), and finally undergo ultrasonic treatment for 0.5-2 hours (such as 0.5, 1, 1.5 or 2 hours) to obtain a composite hydrolyzate (also denoted as TEOS Composite hydrolyzate); Specifically, step (1) is: at room temperature, take a certain quality of TEOS, H 3 PO 4 and deionized water according to n(TEOS): n(H 3 PO 4 ): n(H 2 O)=(0.5~1):(0.005~0.05):(1~20), preferably 1:(0.015~0.025)...

Embodiment 1

[0069] ① Preparation of hybrid nanofiber membrane

[0070] Preparation of TEOS composite hydrolyzate: at room temperature, take TEOS (orthoethyl silicate), H 3 PO 4 (phosphoric acid) and deionized water according to n(TEOS): n(H 3 PO 4 ): n(H 2(2)=1:0.02:10 molar ratio mixes, is placed on magnetic stirrer and stirs 12 hours, obtains hydrolyzate; Then adds titanium dioxide nanopowder in hydrolyzate, guarantees that titanium dioxide nanopowder accounts for 2% of the quality of hydrolyzate, Stir for 5 hours and ultrasonically treat for 1 hour to disperse the titanium dioxide nanopowder in the hydrolyzate evenly to obtain a TEOS composite hydrolyzate.

[0071] Preparation of PVA aqueous solution: Weigh polyvinyl alcohol powder and add it to deionized water, dissolve it by heating at 80°C, and stir for 5 hours; take it out after stirring, put it on a magnetic stirrer at room temperature and stir to dissipate heat until it drops to room temperature; The mass fraction of the pre...

Embodiment 2

[0085] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0086] In step ①, the preparation of the TEOS composite hydrolyzate is as follows: at room temperature, take TEOS, H 3 PO 4 and deionized water according to n(TEOS): n(H 3 PO 4 ): n(H 2 (2)=1:0.02:10 molar ratio mixes, is placed on magnetic stirrer and stirs 12 hours, obtains hydrolyzate; Add titanium dioxide nanopowder in hydrolyzate subsequently, guarantee that titanium dioxide nanopowder accounts for 1% of the quality of hydrolyzate, Stir for 6 hours and ultrasonically treat for 1 hour to disperse the titanium dioxide nano powder in the hydrolyzate evenly to obtain a TEOS composite hydrolyzate.

[0087] The performance test of the highly elastic radiation-resistant nanofiber airgel material in Example 2 is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com