Irradiation-resistant Cu-containing nanocluster reinforced high-strength low-alloy steel and preparation method thereof

A technology of nano-clusters and low-alloy steel, applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems such as material failure, material swelling effect, and hidden dangers of mobile nuclear power safety, and achieve excellent durability Radiation performance, improvement of radiation resistance performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

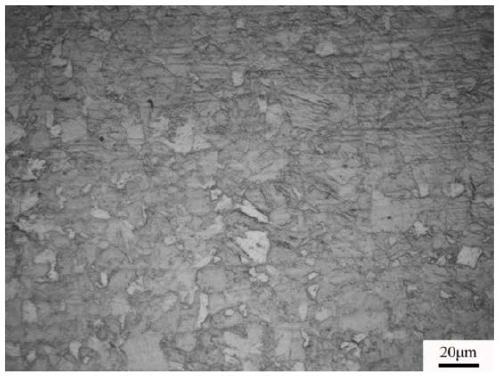

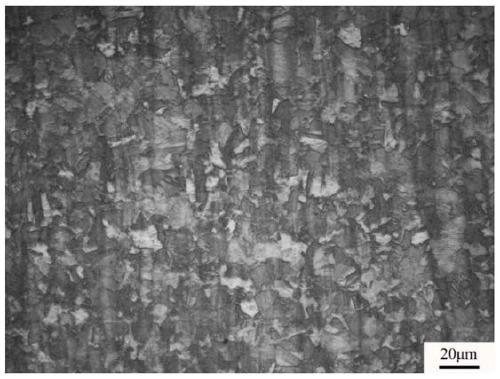

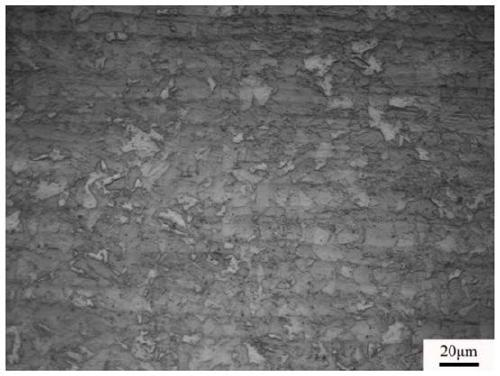

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] The invention belongs to the technical field of nuclear structure materials and their preparation, and in particular relates to a radiation-resistant Cu nano-cluster-containing reinforced high-strength low-alloy steel and a preparation method thereof. The object is to provide a radiation-resistant Cu nano-cluster-containing reinforced high-strength low-alloy steel with high strength and high elongation and a preparation method thereof.

[0030] For realizing the purpose of the present invention, the technical scheme that adopts is:

[0031] A radiation-resistant high-strength low-alloy steel reinforced with Cu nano-clusters, the composition and mass percentage of which are: Cu0.5-4.0%, Ni0.5-6.0%, Mn0.2-2.0%, Cr0.1-1.5 %, Mo0.2-1.5%, Al0-0.5%, Nb0-0.5%, and the balance is iron.

[0032] A method for preparing radiation-resistant Cu nanocluster-contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com