High-impact high-flame-retardant weather-resistant PBT/PC alloy material

An alloy material and a high flame retardant technology are applied in the field of PBT/PC alloy material with high impact resistance, high flame retardant and weather resistance and its preparation field, which can solve the problems of unsatisfactory mechanical properties, difficult processing, poor heat resistance and weather resistance of ABS, etc. , to achieve good comprehensive mechanical properties and physical properties, improve mechanical properties and physical properties, and outstanding hydrolysis resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the present invention, a method of preparing a PBT / PC alloy material having a weather resistance high-resistant high flame retardant, and specifically includes the steps of:

[0039] According to the ratio of weight parts, the raw material will be placed in a high-speed mixer, and the mixture is stirred with a high-speed mixer for 2 to 5 minutes, and then mixed with a twin-screw extruder, cooling, Pienketicles were obtained, and the PBT / PC alloy material was obtained. Among them, the temperature of the twin screw extruder is 200 to 250 ° C, the screw rotation speed is 35 to 55 Hz.

Embodiment 1

[0046] The preparation method of the PBT / PC alloy material is: 37 parts of PBT, 15 parts of PC, 40 parts of weather particles, 12 parts of the composite toughening agent, and antioxidants, and antioxidants. 168 0.1 parts, silicone 0.2 parts, three parts of trioxide, nuccarbonate, 0.6 titanium white powder, 0.1 parts of anhydrous phosphate, 0.1 parts of Polytetrafluoroethylene and UV absorbent 0.1 Add 2 to 5 minutes in the high-speed mixer, discharge; blended granules with a twin screw extruder to prepare a PBT / PC alloy material. Among them, the composite toughening agent consists of 4 parts of EMA and 8 parts, the twin screw extruded processing temperature 200 ~ 250 ° C, the screw rotation speed is 35 ~ 55 Hz. The specific segment temperature of the double screw extruder is shown in Table 2.

Embodiment 2~5

[0048] The PBT / PC alloy material was prepared according to the above-described embodiments, and the difference between the addition of the raw material is different, and the specific formulation and numerical value can be seen in Table 1, and the double screw extruder is provided in the preparation method of Examples 2 to 5. Table 2 is shown in the specific period.

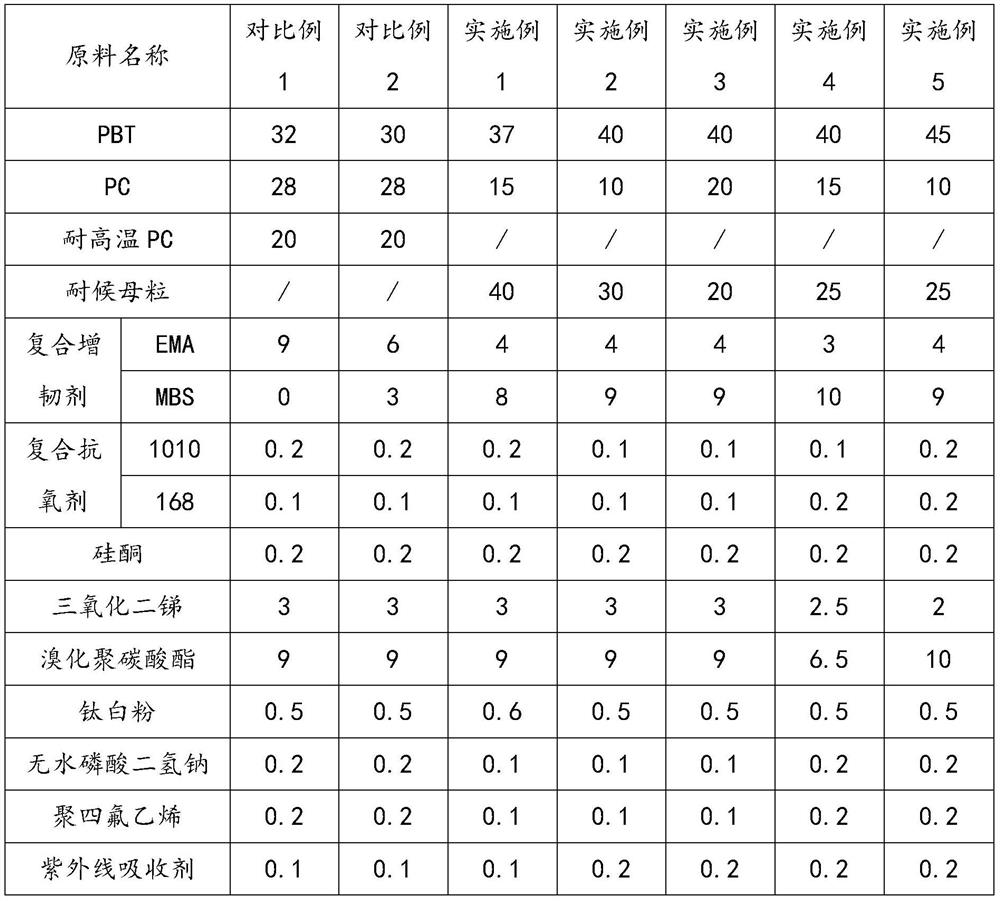

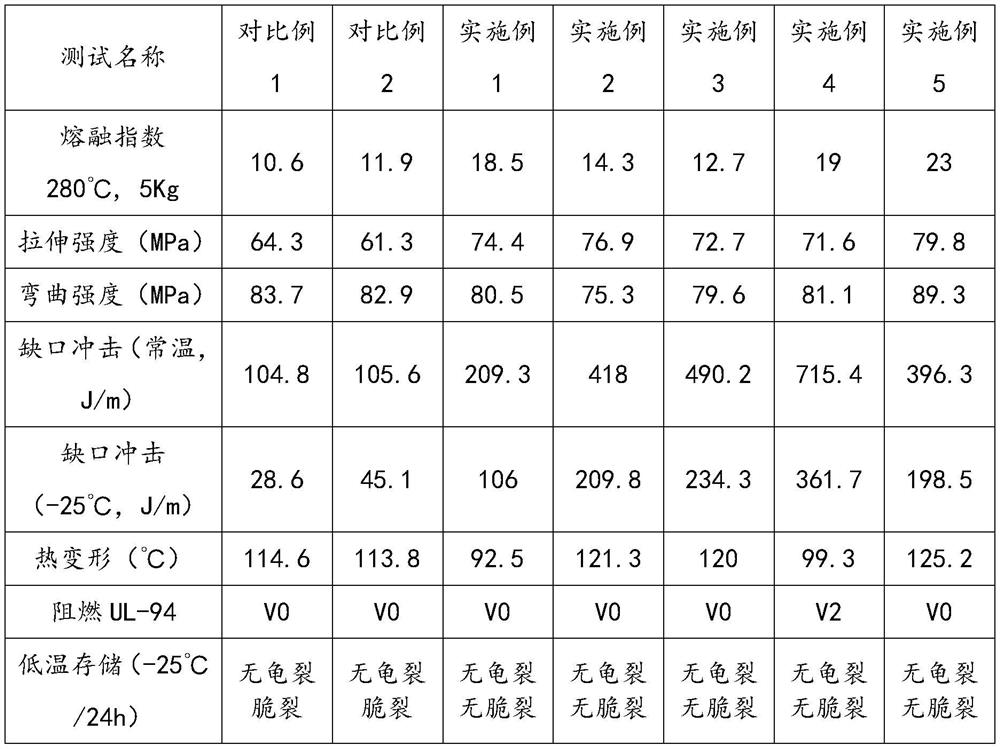

[0049] Table 1 Example 1 to 5 and Comparative Example 1 Alloy Materials and Number of Parts

[0050]

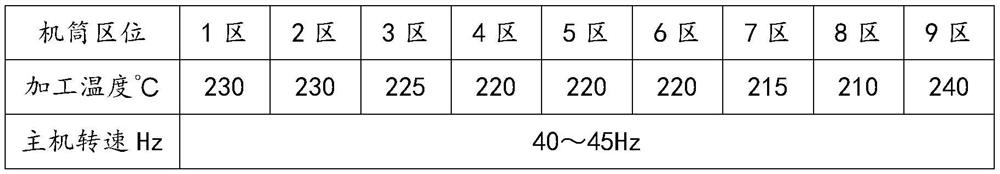

[0051] Table 2 Two-screw extruder each region temperature and host speed setting

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com