Process for deep impurity removal and resource recovery of gold smelting wastewater

A technology of deep impurity removal and resource utilization, applied in the fields of metallurgical wastewater treatment, metal cyanide, simple alkali metal cyanide, etc., can solve the problems of increasing the amount of acid, no profit, and inability to reuse, and achieves a moderate and stable vulcanization reaction. Avoid violent reactions and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

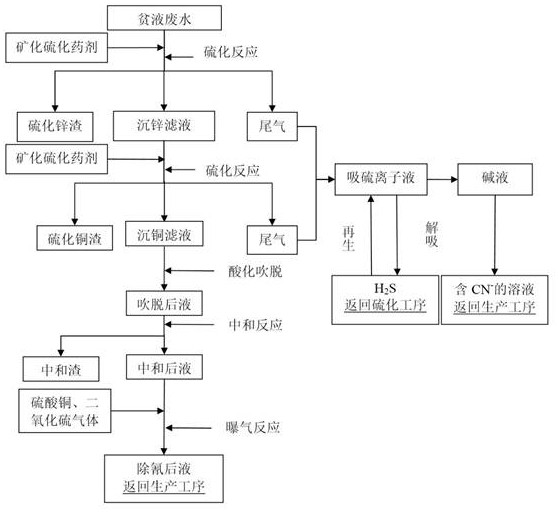

[0052] One kind of impurity and gold smelting Wastewater RECYCLING processes, such as figure 1 As shown, including the following steps:

[0053] Sl, taken 2L lean liquid waste generated during the smelting of gold, 18 mL was added, at a concentration of 0.5g / mL sulfuric acid solution, adjusted to pH 5.2, was added 20mL mineralization vulcanizing agent IH vulcanization reaction, solid-liquid separation, vulcanized Shen filtrate and zinc dross, zinc sulfide residue which is returned to the extraction process of zinc. This step, the molar ratio of available sulfur vulcanizing agents employed in the mineralization of the lean liquid wastewater zinc was 1:1; sulfide mineralization agent employed by ferrous sulfate, sulfide after mixing calcium hydroxide and water to obtain, is a species presents a mixed liquid slurry form, wherein the mass ratio of ferrous sulfate and calcium sulfide is 3.86:1, calcium sulfide to water mass ratio of 1:10; raw water lean liquid used is wastewater: Zn ...

Embodiment 2

[0066] One kind of impurity and gold smelting Wastewater RECYCLING processes, such as figure 1 As shown, including the following steps:

[0067] Sl, taken 2L lean liquid waste generated during the smelting of gold, was added 14mL, at a concentration of 0.5g / mL sulfuric acid solution, adjusted to pH 5.6, was added 15mL mineralization vulcanizing agent IH vulcanization reaction, solid-liquid separation, vulcanized Shen filtrate and zinc dross, zinc sulfide residue which is returned to the extraction process of zinc. This step, the molar ratio of available sulfur vulcanizing agents employed in the mineralization of the lean liquid wastewater zinc was 1:1; sulfide mineralization agent employed by ferrous sulfate, sulfide after mixing calcium hydroxide and water to obtain, is a species presents a mixed liquid slurry form, wherein the mass ratio of ferrous sulfate and calcium sulfide is 3.86:1, calcium sulfide to water mass ratio of 1:10; raw water lean liquid used is wastewater: Zn 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com