Antibacterial warm-keeping chemical fiber fabric and preparation method thereof

A fabric and chemical fiber technology, applied in the field of antibacterial and warm-keeping chemical fiber fabrics and their preparation, can solve the problems of poor antibacterial performance, poor comprehensive properties such as chemical fiber fabric elasticity and mechanical strength, poor thermal performance, etc., and achieve good warmth retention and good antibacterial Antibacterial effect, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

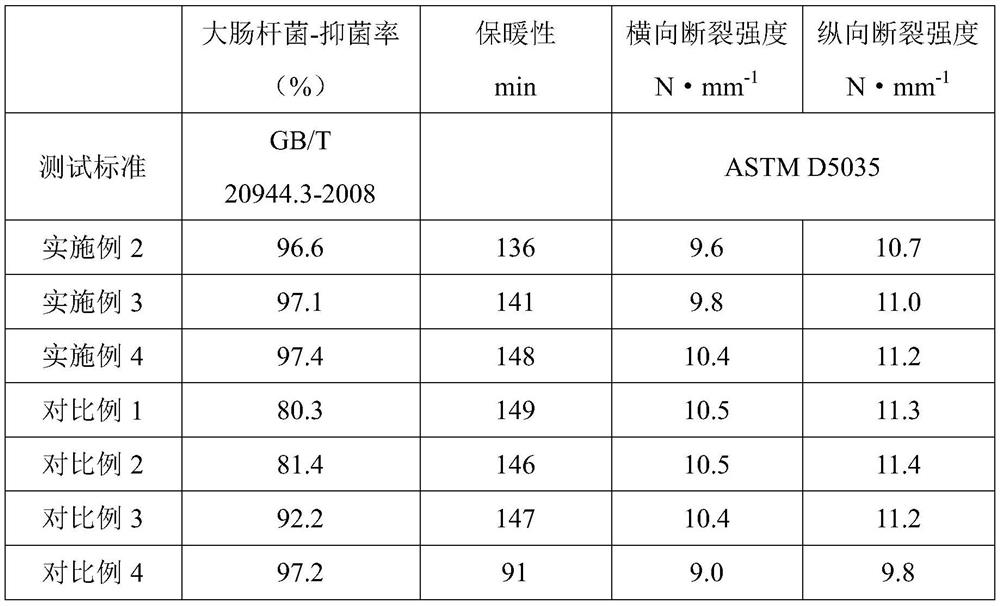

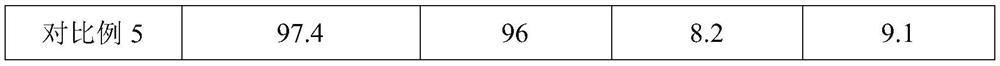

Examples

Embodiment 1

[0048] An antibacterial and warm-keeping chemical fiber fabric, the antibacterial and warm-keeping chemical fiber fabric is made of antibacterial and warm-keeping composite fiber through knitting or weaving process;

[0049] The antibacterial and warm-keeping composite fiber is made of raw materials comprising the following parts by weight:

[0050] 70-80 parts of ethylene terephthalate,

[0051] 18-24 parts of polyacrylonitrile,

[0052] 7-10 parts of polyurethane elastomer,

[0053] 1.8-2.2 parts of silver sulfadiazine,

[0054] 2.3-2.8 parts of chitosan quaternary ammonium salt,

[0055] 3 to 4 parts of calcium silicate nanochips,

[0056] Silica airgel 2.2~2.6 parts,

[0057] 3 to 5 parts of processing aids.

[0058] In this embodiment, the antibacterial and warm-keeping composite fiber is preferably made of raw materials including the following parts by weight:

[0059] 75 parts of ethylene terephthalate,

[0060] 21 parts of polyacrylonitrile,

[0061] 8.5 parts...

Embodiment 2

[0079] An antibacterial and warm-keeping chemical fiber fabric, the antibacterial and warm-keeping chemical fiber fabric is made of antibacterial and warm-keeping composite fiber through knitting or weaving process;

[0080] The antibacterial and warm-keeping composite fiber is made of raw materials comprising the following parts by weight:

[0081] 70 parts of ethylene terephthalate,

[0082] 18 parts of polyacrylonitrile,

[0083] 7 parts of polyurethane elastomer,

[0084] 1.8 parts of silver sulfadiazine,

[0085] Chitosan quaternary ammonium salt 2.3 parts,

[0086] 3 parts of calcium silicate nanochips,

[0087] Silica airgel 2.2 parts,

[0088] 3 parts of processing aids.

[0089] In this embodiment, the polyurethane elastomer is tetrahydrofuran homopolyether polyurethane elastomer.

[0090] In the present embodiment, the degree of substitution of the chitosan quaternary ammonium salt is 87%, and the molecular weight is 8.7×10 4 u.

[0091] In this embodiment, ...

Embodiment 3

[0101] An antibacterial and warm-keeping chemical fiber fabric, the antibacterial and warm-keeping chemical fiber fabric is made of antibacterial and warm-keeping composite fiber through knitting or weaving process;

[0102] The antibacterial and warm-keeping composite fiber is made of raw materials comprising the following parts by weight:

[0103] 80 parts of ethylene terephthalate,

[0104] 24 parts of polyacrylonitrile,

[0105] 10 parts of polyurethane elastomer,

[0106] 2.2 parts of silver sulfadiazine,

[0107] Chitosan quaternary ammonium salt 2.8 parts,

[0108] 4 parts of calcium silicate nanochips,

[0109] Silica airgel 2.6 parts,

[0110] 5 parts of processing aids.

[0111] In this embodiment, the polyurethane elastomer is tetrahydrofuran homopolyether polyurethane elastomer.

[0112] In the present embodiment, the degree of substitution of the chitosan quaternary ammonium salt is 89%, and the molecular weight is 9.1×10 4 u.

[0113] In this embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com