Preparation method of lithium iron phosphate and application thereof

A technology of lithium iron phosphate and phosphate solution, which is applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., and can solve the problems of high cost of anhydrous iron phosphate products, long production process of anhydrous iron phosphate, and labor costs. Solve the problems of high consumption of energy and energy, and achieve the effect of simple and easy preparation method, large amount of by-products of titanium dioxide, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

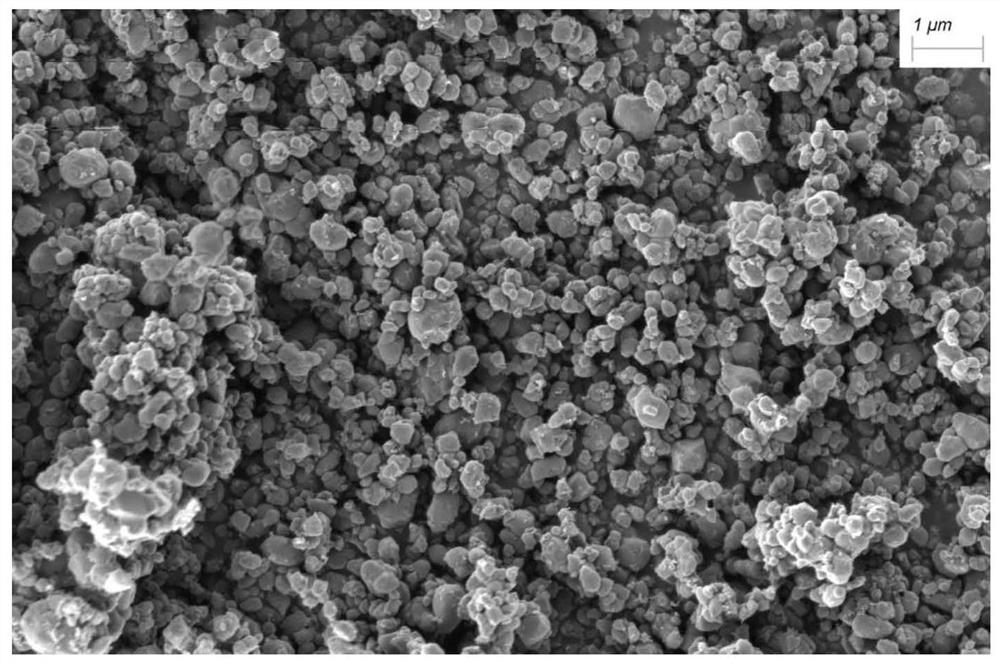

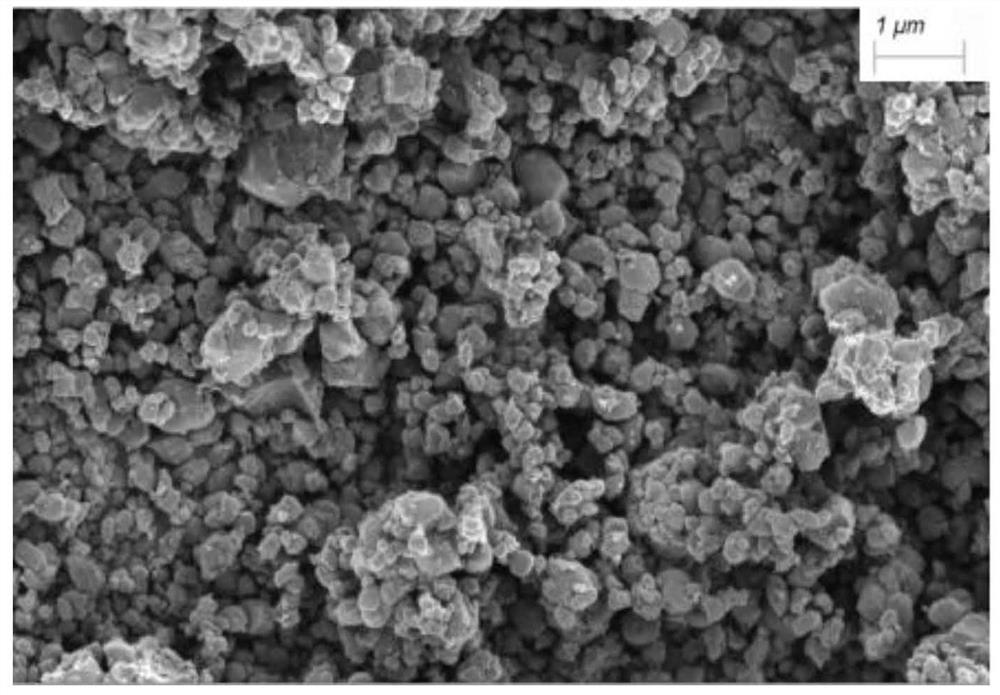

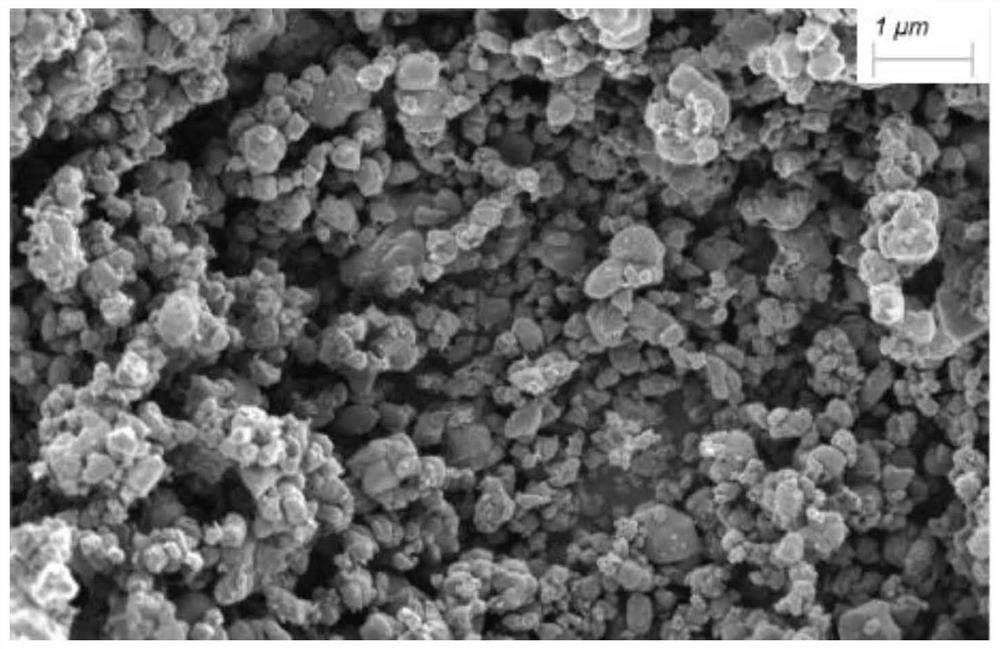

Image

Examples

Embodiment 1

[0070] The method of preparing lithium iron phosphate according to the present embodiment includes the following steps:

[0071] (1) Titanium white by-product seven-water sulfate is dissolved, reduced (during reduction, using iron powder, and holding pH = 3.5), filtrate, clarify, to obtain a pure mass concentration of 250 g / L Sulfate solution; simultaneously dissolved in a certain amount of pure water at the same time, adding ammonia water to 7.2, configure a phosphophosphate solution having a phosphorus content of 10%.

[0072] (2) The ferrous sulfate solution, the phosphate solution is heated to a certain concentration, maintaining the temperature of the two solutions of 45 ° C, iron and phosphorus of 0.97, synchronously added to the closed reactor synthesis, reaction 60min Then, then the reactor continued to be expressed, under stirring conditions, the temperature was raised to 90 ° C with vapor, and the reaction time was continued to obtain a reaction material.

[0073] (3) ...

Embodiment 2

[0079] The method of preparing lithium iron phosphate according to the present embodiment includes the following steps:

[0080] (1) Titanium white by-product seven-water sulfate is dissolved, reduced (during reduction, using iron powder, and maintains pH = 3.5), filtrate, clarify, to obtain a pure mass concentration of 280 g / L Sulfate solution; simultaneously dissolved in a certain amount of pure water at the same time, adding ammonia water to 8.8 to 8.8, configure a phosphoric acid solution having a phosphorus content of 8%.

[0081] (2) The ferrous sulfate solution, the phosphate solution, and the phosphate solution, respectively, to a certain concentration, maintain two solution temperatures of 55 ° C, the molar ratio of iron and phosphorus is 0.98, synchronously added to the closed reactor synthesis, reaction 80 min Then, then enter the reaction kettle to continue, under stirring conditions, the temperature was raised to 95 ° C with vapor, and the reaction time was continue...

Embodiment 3

[0088] The method of preparing lithium iron phosphate according to the present embodiment includes the following steps:

[0089] (1) Titanium white by-product seven water sulfate is dissolved, reduced (during reduction, using iron powder, and holding pH = 4), filtrate, clarify, to obtain a pure mass concentration of 310g / L Sulfate solution; simultaneously dissolve ammonium phosphate in a certain amount of pure water, adding ammonia water to 8.0, configure a phosphoric acid solution having a phosphorus content of 12%.

[0090] (2) A ferrous sulfate solution, phosphate solution is heated to a certain concentration, maintaining two solution temperatures of 48 ° C, iron and phosphor ratio of 1, synchronously added to the closed reactor synthesis, reaction 70min Then, then entering the reactor to continue, then under stirring, the temperature was raised to 98 ° C with vapor, and the reaction time was continued for 2.5 h, resulting in the reaction material.

[0091] (3) After filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com