High-corrosion-resistance flexible copper-clad plate and preparation method thereof

A flexible copper clad laminate, high corrosion resistance technology, used in flexible printed circuit boards, printed circuit manufacturing, manufacturing printed circuit precursors, etc., can solve the problem that the alloy layer is not crystallized, uniform, and corrosion resistance is not ideal. , the problem of low service life of flexible copper clad laminates, etc., to achieve the effect of improving service life, meticulous and close crystallization, and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

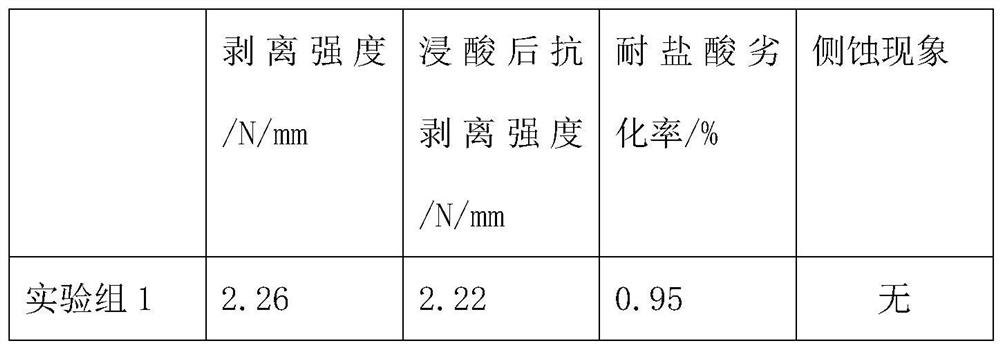

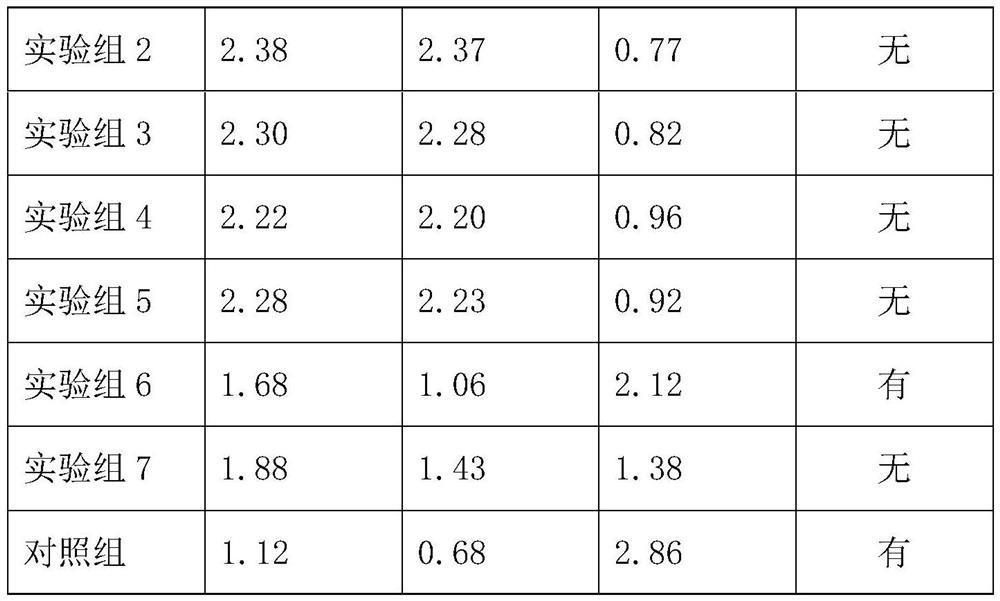

Examples

Embodiment 1

[0025] The invention provides a flexible copper-clad laminate with high corrosion resistance, which comprises an insulating substrate and a copper foil layer, a transition layer is provided between the insulating substrate and the copper foil layer, and a corrosion-resistant coating is provided on the outside of the copper foil layer. layer, the transition layer is an active electrode material layer, and the corrosion-resistant layer includes a galvanized layer and a nanometer coating.

[0026] In a preferred embodiment, the insulating substrate is an organic polymer film, and the organic polymer film is PI.

[0027] In a preferred embodiment, the active electrode material layer is Ni, and the thickness of the transition layer is 500 nm.

[0028] In a preferred embodiment, the thickness of the copper foil layer is 25um, the thickness of the galvanized layer is 400nm, and the thickness of the nano-coating layer is 250nm.

[0029] In a preferred embodiment, the nano-coating inc...

Embodiment 2

[0040] The invention provides a highly corrosion-resistant flexible copper-clad laminate. The nano-coating includes the following raw materials in weight percentage: 60% of nano-silicon dioxide, 20% of nano-titanium dioxide, 10% of polyaniline and 10% of polypyrrole.

Embodiment 3

[0042] Different from Examples 1 and 2, the present invention provides a flexible copper-clad laminate with high corrosion resistance, and the nano-coating includes the following raw materials in weight percentage: 45% of nano-silicon dioxide, 25% of nano-titanium dioxide, poly Aniline 15% and polypyrrole 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com