Coprinus comatus mycelium polysaccharide as well as preparation method and application thereof

A technology of mycelium polysaccharides and Coprinus comatus, applied in biochemical equipment and methods, methods based on microorganisms, pharmaceutical formulations, etc., can solve the problems that affect the wide application of Coprinus comatus polysaccharides, vulnerability to climate influence, long cultivation cycle and cost and other problems, to achieve good antioxidant activity, easy to control growth, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Inoculate Coprinus comatus bacteria into a plate containing PDA, activate it in a constant temperature incubator at 28°C, and wait until the mycelia cover the plate. Take 1cm with a sterile punch 2 Mycelium was inoculated into 200mL liquid medium (potato 20.0g, glucose 2.0g, MgSO 4 ·7H 2 0 1.5g, KH2 PO 4 1.5 g, 1000 mL of water, the pH of which is 7), static culture at 26.5° C. for 1 day, and then shake on a rotary shaker at 180 rpm for 7 days to obtain a liquid culture solution. The liquid culture solution is dried at 80° C., crushed and passed through a 200-mesh sieve to obtain Coprinus comatus mycelium powder.

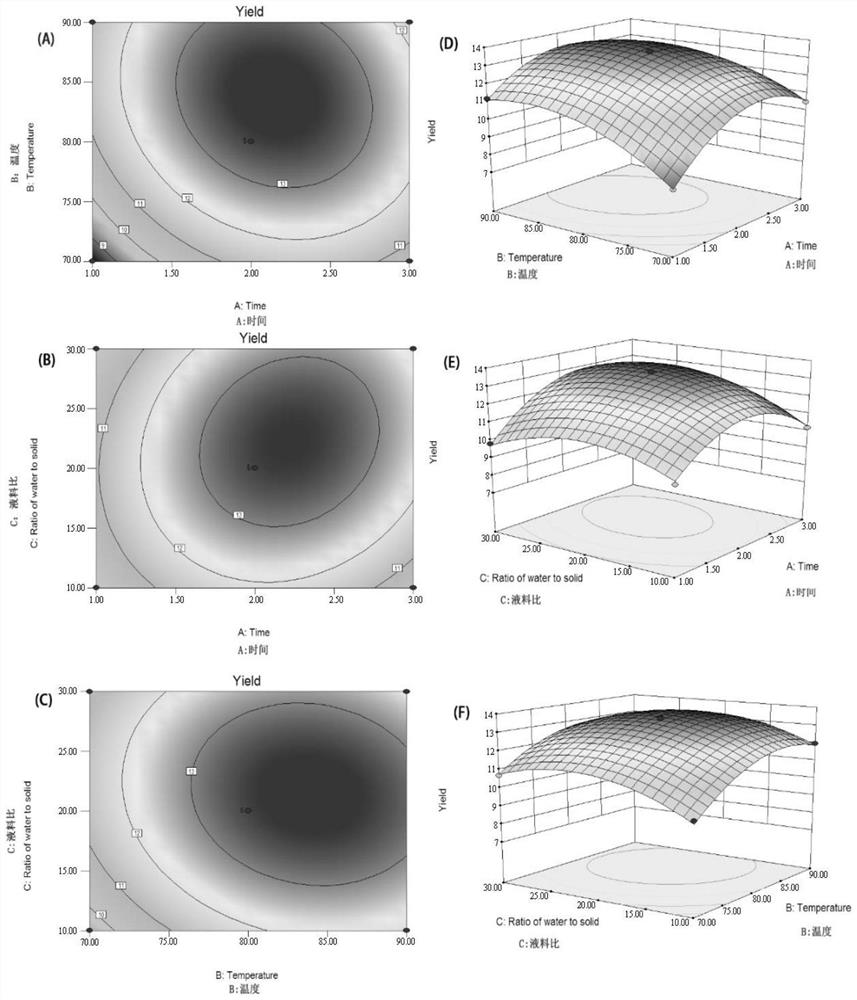

[0041] (2) Single factor experiment: using water as the extraction solvent, the extraction time (1, 2, 3, 4, 5h), the extraction temperature (50, 60, 70, 80, 90, 100°C), the ratio of solid to liquid ( 10:1, 20:1, 30:1, 40:1, 50:1mL / mg) as variables, taking the yield of polysaccharide (IPS) as a reference, the hydrothermal treatment of Coprinus comatu...

Embodiment 2

[0067] (1) obtain Coprinus comatus mycelium by fermenting and cultivating according to the optimal culture condition of embodiment 1, get Coprinus comatus mycelium drying and pulverizing, pour it into 200 mesh sieves subsequently and obtain Coprinus comatus mycelium powder;

[0068] (2) According to the optimized experimental conditions in Example 1, under actual operation, the optimal extraction process was adjusted to a liquid-to-solid ratio of 21:1 and leaching in a hot water bath at 81°C for 2 hours to obtain an extract;

[0069] (3) After filtering the extract, centrifuge and collect the supernatant: filter the extract with a sieve, and centrifuge the obtained liquid mixture at 3000r / min for 15min, collect the supernatant and carry out concentrated dialysis;

[0070] (4) Add absolute ethanol (final concentration: 75%) to the collected supernatant, then let it stand overnight at 4°C, discard the supernatant and collect the precipitate;

[0071] (5) Freeze-drying: place the...

Embodiment 3

[0094] Example 3 Research on Antioxidant Activity of Coprinus comatus Mycelia Polysaccharides

[0095] Antioxidative ability of polysaccharides and 2,2-azino-bis(3-ethyl-benzothiazole-6-sulfonic acid) diammonium salt (ABTS) free radical, 1,1-diphenyl-2-trinitrate It is related to the scavenging and reducing ability of diphenylhydrazine (DPPH) free radicals, hydroxyl free radicals, and superoxide anion free radicals. This embodiment measures the scavenging rates of these five free radicals to determine their antioxidant capacity.

[0096] (1) ABTS free radical scavenging activity:

[0097] ① ABTS stock solution (7.4mmol / L) and potassium persulfate (K 2 S 2 o 8 ) stock solution (2.6mmol / L) was mixed at a volume ratio of 1:1, stored in the dark for 16 hours, diluted 40-50 times with pH 7.4 phosphate buffer (0.01mol / L), and then measured at a wavelength of 734nm. Finally, the absorbance of the solution is stabilized at A 734nm =0.700±0.01. The sample concentration is 0.5, 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com