A method for eliminating mixed crystals in s31035 high-alloy austenitic heat-resistant steel

A technology of austenitic heat-resistant steel and alloy, which is applied in metal rolling and other directions, can solve the problems of uneven structure of high-alloy austenitic heat-resistant stainless steel, achieve uniform structure, eliminate mixed crystal defects, and have strong feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for eliminating mixed crystals in the S31035 high-alloy austenitic heat-resistant steel of the present embodiment is as follows:

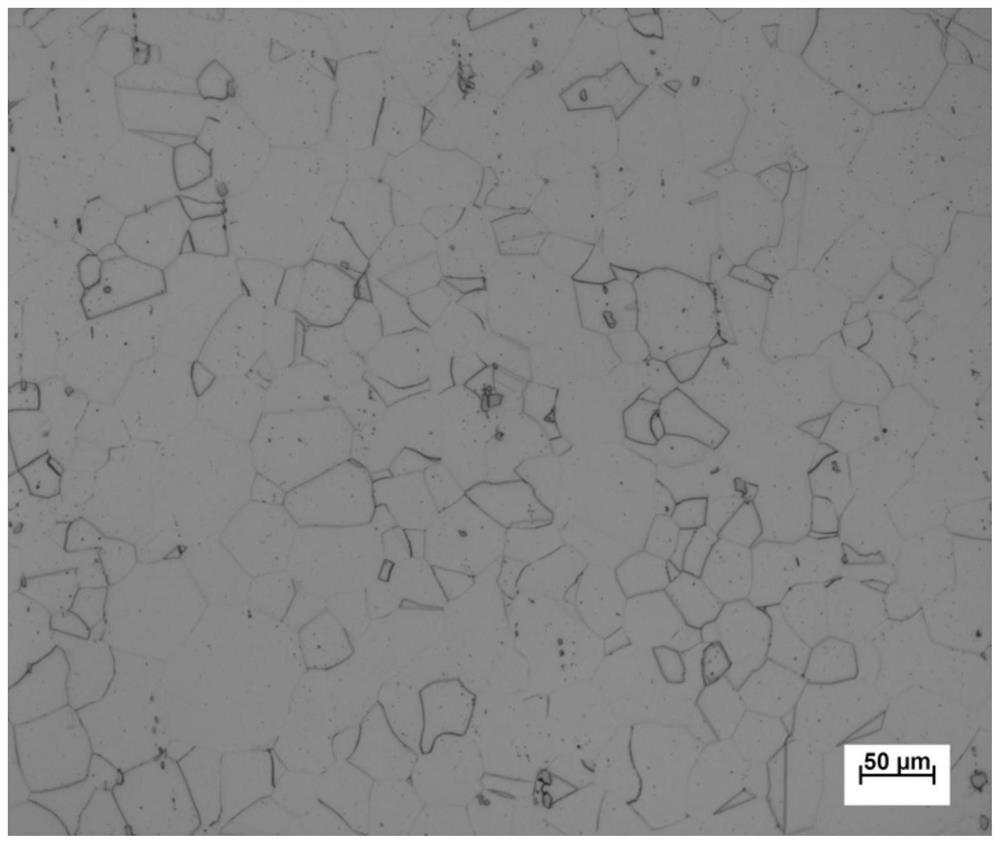

[0038] (1) The experimental material is S31035 steel pipe φ120mm×35mm. The S31035 steel pipe is prepared by the current conventional hot extrusion process. The specific process belongs to the existing conventional technology, and will not be repeated here. Cut 20×20×20mm from S31035 steel pipe 3 Sample, effective thickness D=20mm. The chemical composition analysis and metallographic structure analysis were carried out. The chemical composition results are shown in Table 1, and the metallographic structure is shown in Table 1. figure 1 shown, the content of which is very small and does not affect M 23 C 6 The content of P, S, and B calculated from the dissolution temperature is no longer calculated.

[0039] Table 1 Chemical composition (mass percentage content %)

[0040]

[0041] (2) Calculate M 23 C 6 the dissolution t...

Embodiment 2

[0047] The method for eliminating mixed crystals in the S31035 high-alloy austenitic heat-resistant steel of the present embodiment is as follows:

[0048] (1) The experimental material is S31035 steel pipe φ120mm×35mm through hot extrusion process, and 20×20×20mm is cut from S31035 steel pipe 3 Sample, effective thickness D=20mm. Carry out chemical composition analysis and metallographic structure analysis, as shown in the following table:

[0049] Table 2 Chemical composition (mass percentage content %)

[0050]

[0051] (2) Calculate M according to step (1) 23 C 6 The dissolution temperature of M was obtained by thermodynamic calculation software (JMatPro) 23 C 6 The dissolution temperature (Tc) of 1080°C.

[0052] (3) Set the temperature of the heat treatment furnace to Tc-30=1050°C, heat the heat treatment furnace to 1050°C, and put the S31035 steel pipe sample for 0.8 times the effective thickness of the sample (20mm), that is, 16min.

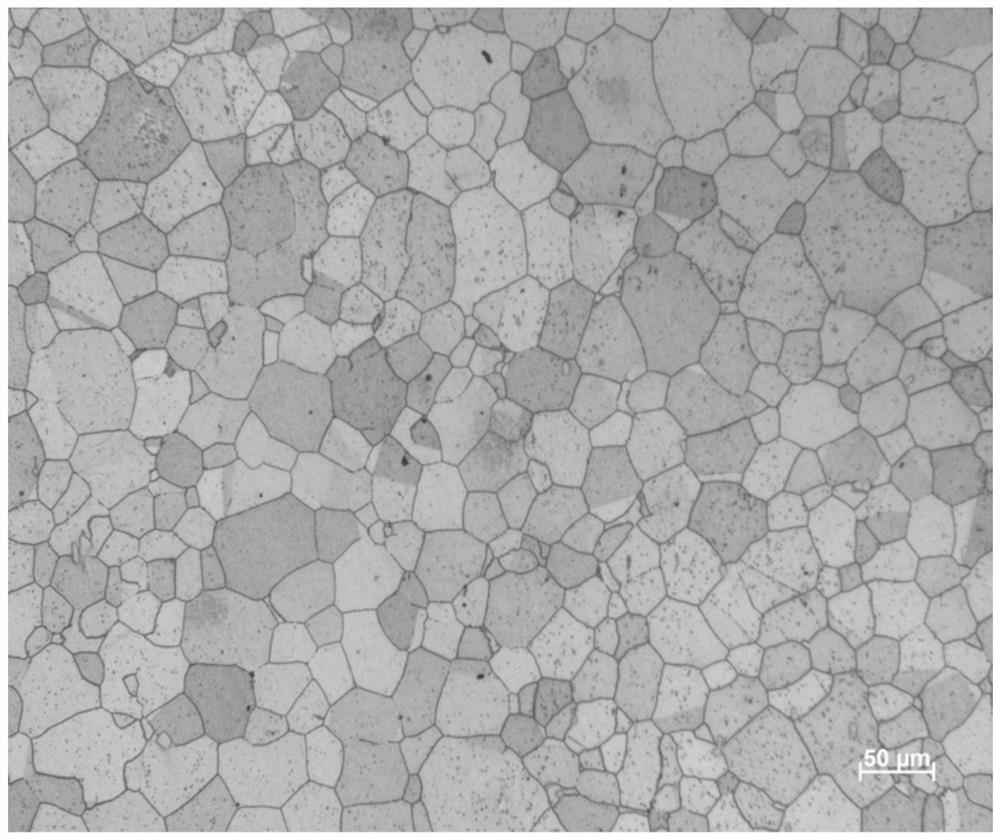

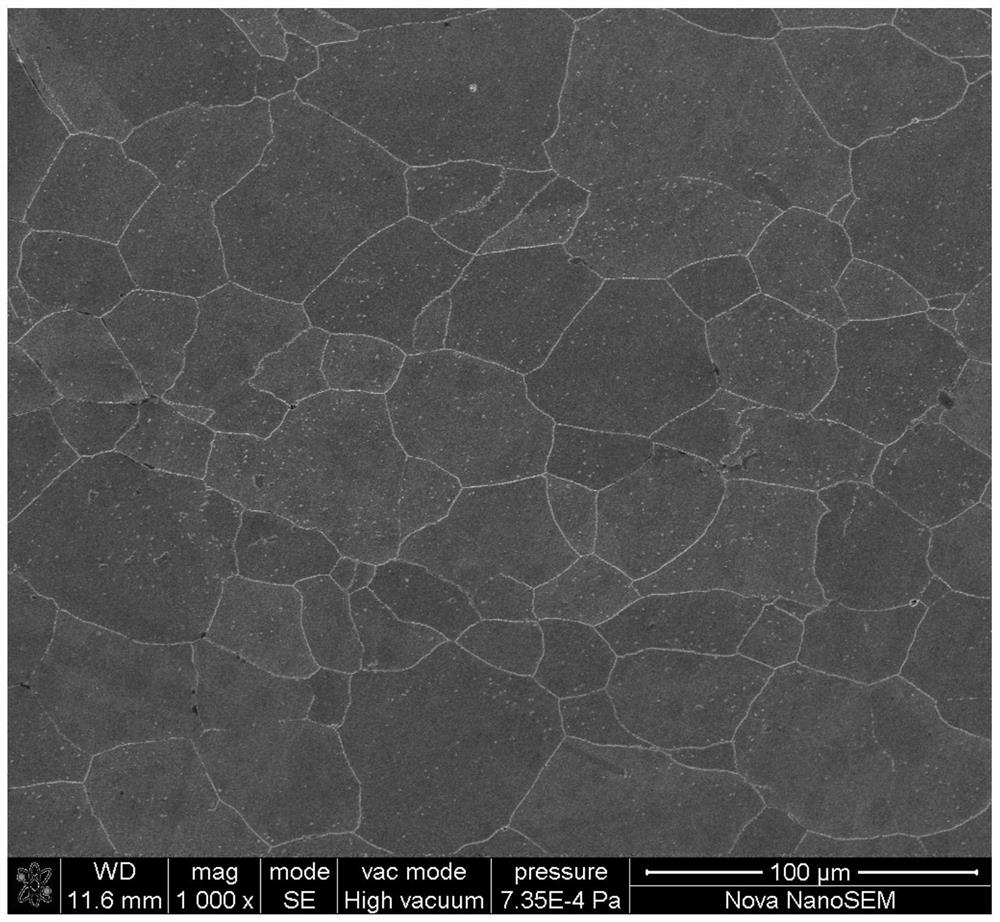

[0053] (4) After the S31...

Embodiment 3

[0057] The method for eliminating mixed crystals in the S31035 high-alloy austenitic heat-resistant steel of the present embodiment is as follows:

[0058] (1) The experimental material is S31035 steel pipe φ120mm×35mm through hot extrusion process, and 50×30×30mm is cut from S31035 steel pipe 3 Sample, effective thickness D=30mm. Carry out chemical composition analysis and metallographic structure analysis.

[0059] Table 3 Chemical composition (mass percentage content %)

[0060]

[0061] (2) According to step (1), the chemical composition is obtained, and M is calculated by thermodynamic software 23 C 6 The dissolution temperature (Tc) of 1050℃.

[0062] (3) Set the temperature of the heat treatment furnace to Tc-100=950°C, heat the heat treatment furnace to 950°C, and put in the S31035 steel pipe sample for 1.2 times the effective thickness (30mm) of the sample, that is, keep the temperature for 36 minutes.

[0063] (4) The S31035 steel pipe sample is rolled after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com