Method for eliminating mixed crystals in S31035 high-alloy austenitic heat-resistant steel

A technology of austenitic heat-resistant steel and alloy, which is applied in metal rolling and other directions, can solve the problems of uneven structure of high-alloy austenitic heat-resistant stainless steel, achieve uniform structure, strong feasibility, and eliminate mixed crystal defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for eliminating mixed crystals in the S31035 high-alloy austenitic heat-resistant steel of the present embodiment, the specific process is as follows:

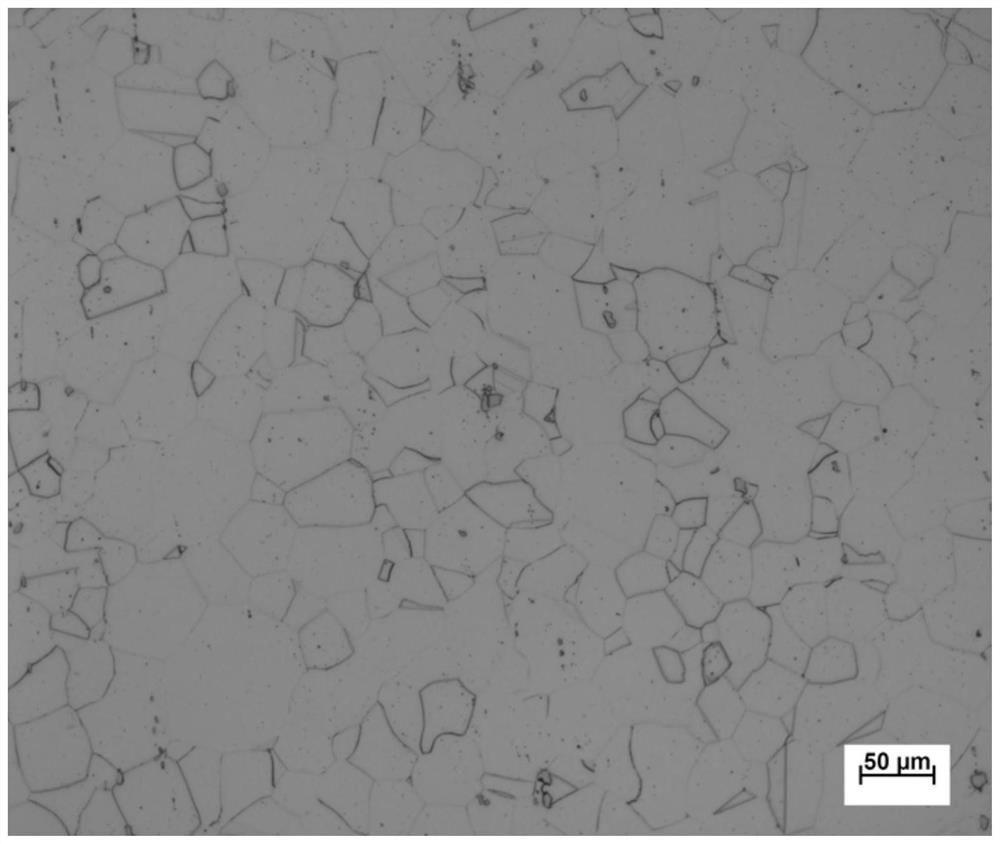

[0038] (1) The experimental material is S31035 steel pipe φ120mm×35mm. The S31035 steel pipe is prepared by the current conventional hot extrusion process. The specific process belongs to the existing conventional technology and will not be repeated here. Cut from S31035 steel pipe 20×20×20mm 3 Sample, effective thickness D = 20mm. Carry out chemical composition analysis and metallographic structure analysis, chemical composition result is shown in table 1, metallographic structure is as follows figure 1 As shown, very little content does not affect M 23 C 6 The P, S, and B contents calculated at the dissolution temperature are no longer calculated.

[0039] Table 1 chemical composition (mass percentage content %)

[0040]

[0041] (2) Calculate M 23 C 6 the melting temperature. By the chemical com...

Embodiment 2

[0047] The method for eliminating mixed crystals in the S31035 high-alloy austenitic heat-resistant steel of the present embodiment, the specific process is as follows:

[0048] (1) The experimental material is S31035 steel pipe φ120mm×35mm through the hot extrusion process, and 20×20×20mm is cut from the S31035 steel pipe 3 Sample, effective thickness D = 20mm. Carry out chemical composition analysis and metallographic structure analysis, as shown in the following table:

[0049] Table 2 chemical composition (mass percentage content %)

[0050]

[0051] (2) Calculate M according to step (1) 23 C 6 The dissolution temperature is obtained by thermodynamic calculation software (JMatPro) M 23 C 6 The dissolution temperature (Tc) is 1080°C.

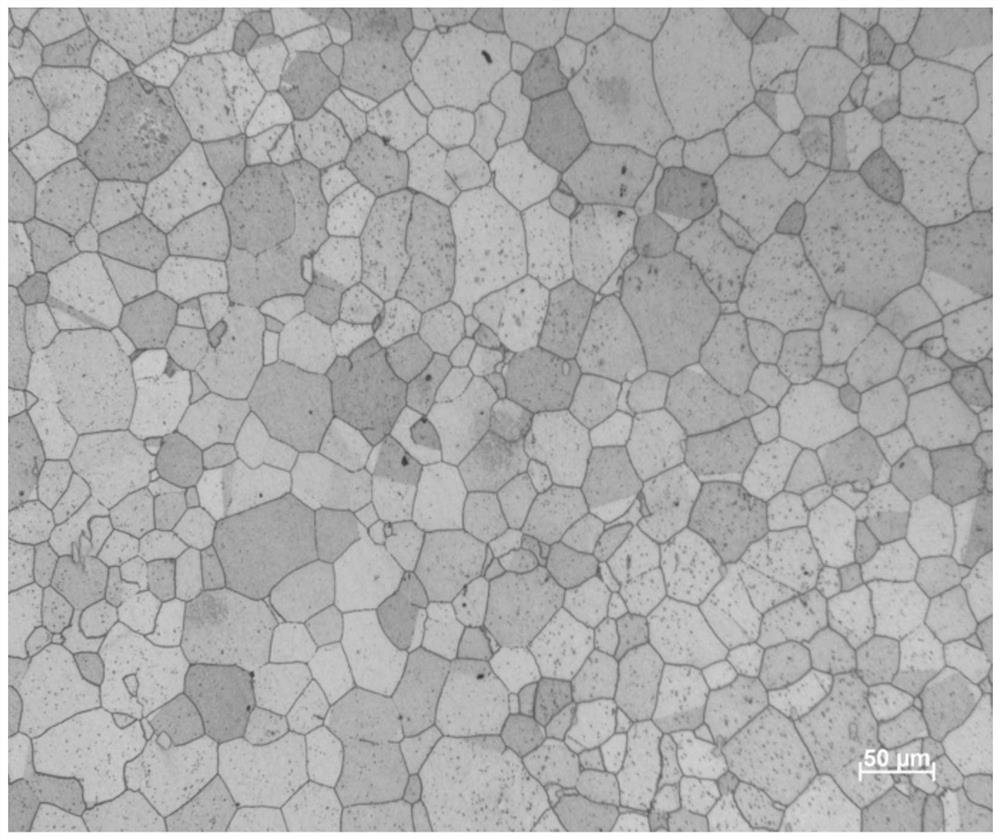

[0052] (3) Set the temperature of the heat treatment furnace at Tc-30=1050°C, raise the temperature of the heat treatment furnace to 1050°C, put the S31035 steel pipe sample into it, and the time is 0.8 times the effective thickness ...

Embodiment 3

[0057] The method for eliminating mixed crystals in the S31035 high-alloy austenitic heat-resistant steel of the present embodiment, the specific process is as follows:

[0058] (1) The experimental material is S31035 steel pipe φ120mm×35mm by hot extrusion process, cut from S31035 steel pipe 50×30×30mm 3 Sample, effective thickness D = 30mm. Carry out chemical composition analysis and metallographic structure analysis.

[0059] Table 3 chemical composition (mass percentage content %)

[0060]

[0061] (2) Obtain the chemical composition according to step (1), and calculate M by thermodynamic software 23 C 6 The dissolution temperature (Tc) is 1050°C.

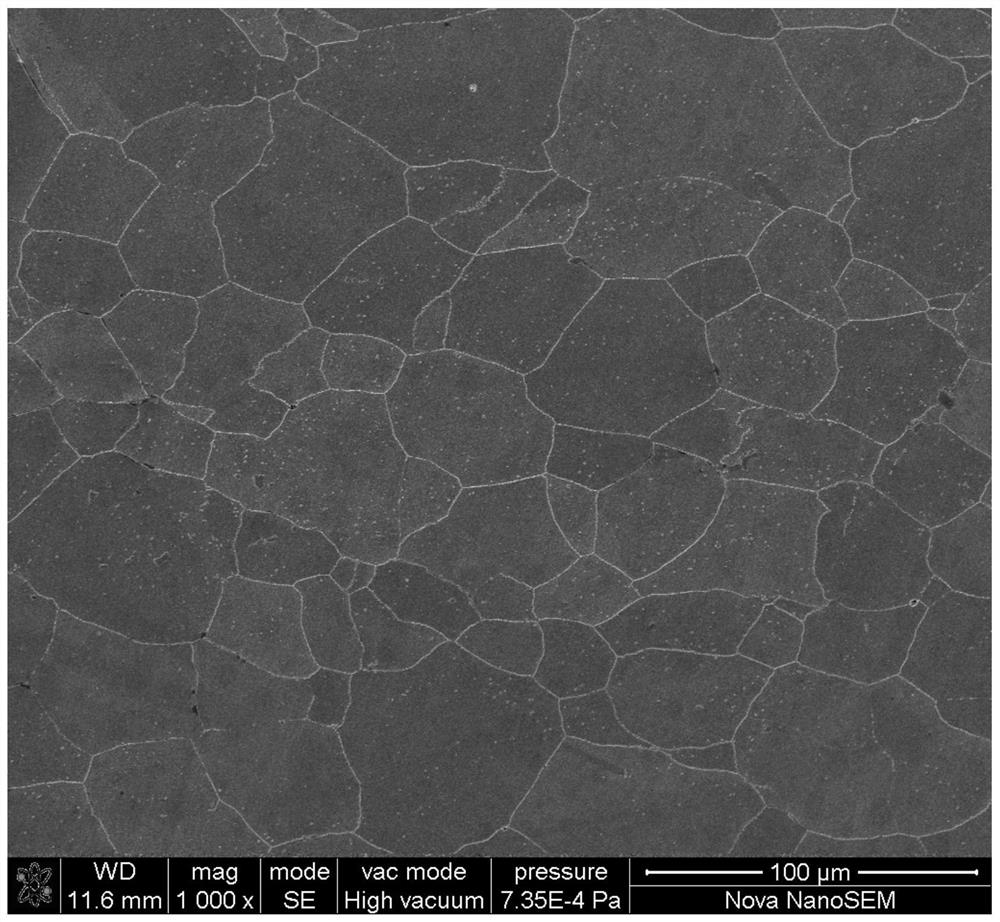

[0062] (3) Set the temperature of the heat treatment furnace to Tc-100=950°C, raise the temperature of the heat treatment furnace to 950°C, put the S31035 steel pipe sample into it, the time is 1.2 times the effective thickness of the sample (30mm), that is, keep it for 36 minutes.

[0063] (4) The S31035 steel pipe sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com