Preparation method of multifunctional ocean engineering alloy

A marine engineering, multi-functional technology, applied in the field of marine metal materials, can solve the problems of difficult and effective mutual solubility, excessive precipitation drive, slow diffusion, etc., to stabilize the free energy of the system, avoid grain boundary segregation, and improve mutual solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

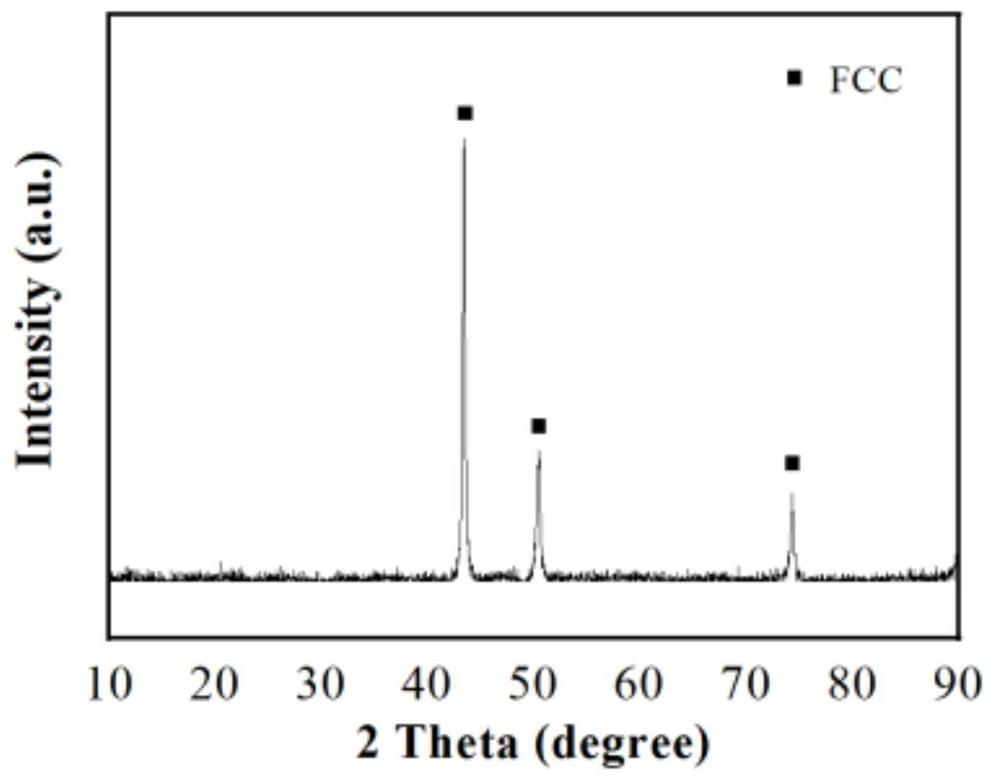

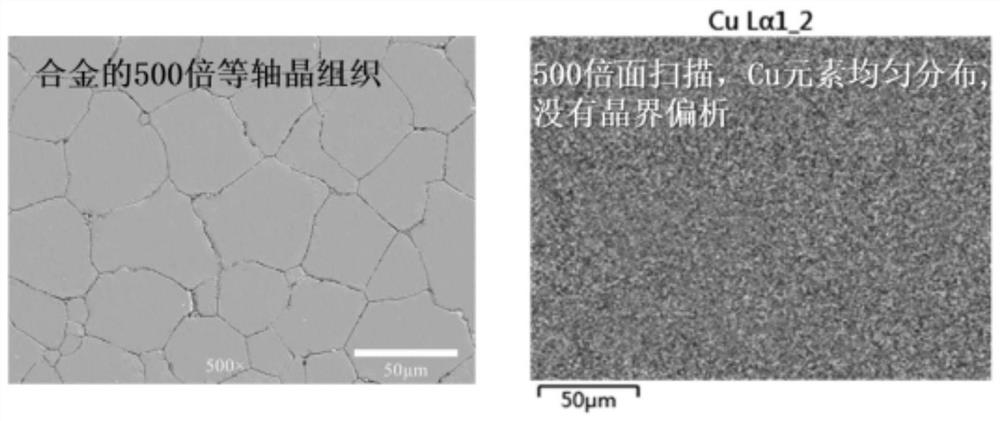

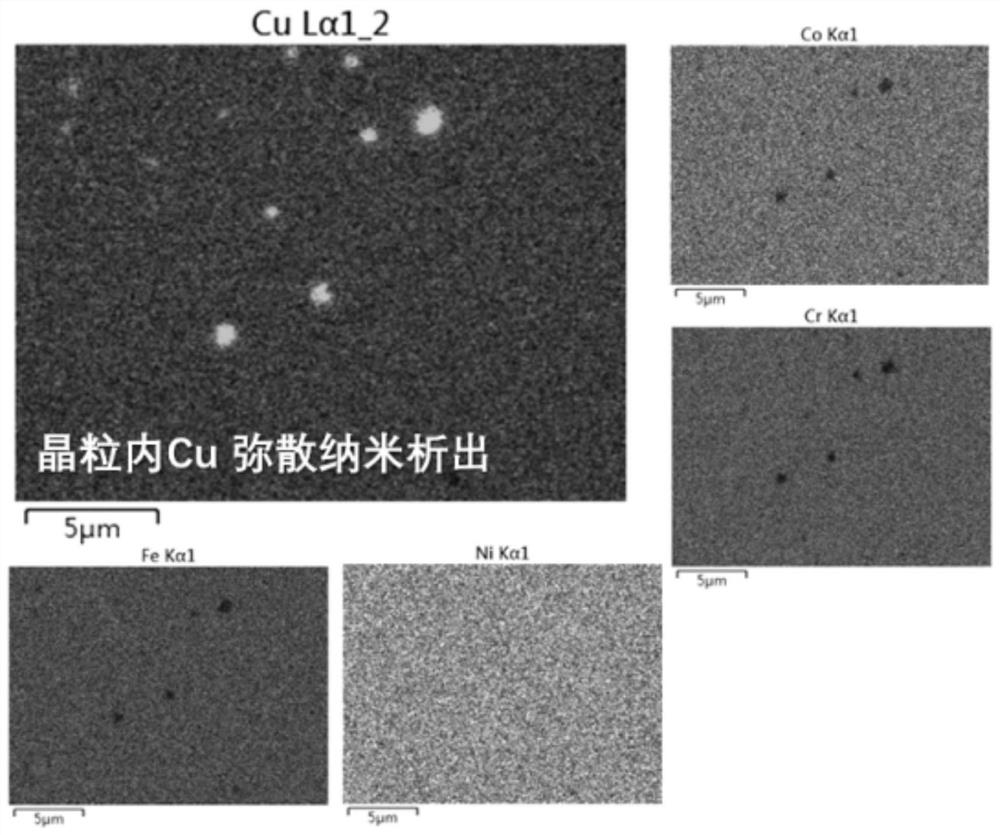

[0041] The preparation method of 85wt%[Co(25)Cr(25)Fe(25)Ni(25)]+15wt%Cu alloy of multifunctional marine engineering alloy:

[0042] 1) Mixed ball mill

[0043] Utilize electronic balance, the Co(25)Cr(25)Fe(25)Ni(25)FCC base high-entropy alloy powder of 85wt% and the Cu powder of 15wt%; The high-entropy alloy powder is an atomized alloy powder, spherical, and particle size is 15-100μm, the purity of Cu powder is >99.9%, and the particle size is 5-50μm; put the weighed metal powder into a ball mill tank for mixing ball milling, the ball-to-material ratio is 2:1, mix at a speed of 200r / min for 12h, and ball mill After drying, a uniform pre-sintered powder is obtained;

[0044] 2) Promote miscible high-temperature sintering

[0045] Put the obtained mixed powder into graphite mold, then place it in SPS discharge plasma sintering furnace, and vacuumize the atmosphere in the furnace to 5×10 -3 Pa, pressurize the graphite mold up and down until the sample is under pressure of 40...

Embodiment 2

[0050] The preparation method of the multifunctional marine engineering alloy 95wt%[Co(20)Cr(30)Fe(30)Ni(20)]+5wt%Cu alloy:

[0051] 1) Mixed ball mill

[0052] Utilize electronic balance, the Co(20)Cr(30)Fe(30)Ni(20)FCC base high-entropy alloy powder of 95wt% and the Cu powder of 5wt%; The high-entropy alloy powder is an atomized alloy powder, spherical, and particle size is 15-100μm, the purity of Cu powder is >99.9%, and the particle size is 5-50μm; put the weighed metal powder into a ball mill tank for mixed ball milling, the ball-to-material ratio is 1:1, mix at a speed of 100r / min for 15h, and ball mill After drying, a uniform pre-sintered powder is obtained;

[0053] 2) Promote miscible high-temperature sintering

[0054] Put the obtained mixed powder into a graphite mold, then place it in an SPS discharge plasma sintering furnace, evacuate the atmosphere in the furnace to 10Pa, pressurize the graphite mold up and down until the sample is under pressure of 30MPa, and ...

Embodiment 3

[0059] The preparation method of multi-functional marine engineering alloy 80wt%[Co(30)Cr(20)Fe(20)Ni(30)]+20wt%Cu alloy:

[0060] 1) Preparation of Co(30)Cr(20)Fe(20)Ni(30)FCC-based high-entropy alloy powder

[0061] Co(30)Cr(20)Fe(20)Ni(30)FCC-based high-entropy alloy bulk was prepared by arc melting, and Co(30)Cr(20)Fe(20)Ni(30)FCC-based high-entropy alloy The block is placed in the atomization powder making equipment, vacuumed <10Pa, and then filled with high-purity argon for protection; the tundish is kept warm at 1400°C for 25 minutes; then the alloy is refined at 1550°C, and the refining time is 5min; Pour the alloy into the tundish, use high-pressure inert gas flow to crush the metal liquid into small droplets and quickly condense it into powder. .

[0062] 2) Mixed ball mill

[0063] Utilize electronic balance, the Co(30)Cr(20)Fe(20)Ni(30)FCC base high-entropy alloy powder of 80wt% and the Cu powder of 20wt%; The high-entropy alloy powder is an atomized alloy powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com