Preparation method and application of aluminum-scandium alloy sputtering target

A sputtering target and alloy technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problem of low alloy ingot composition, affecting the use effect of target material, aluminum-scandium alloy ingot segregation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the preparation method of the aluminum scandium alloy sputtering target is carried out according to the following steps:

[0043] (1) Raw material smelting: In a vacuum intermediate frequency induction furnace, mix Sc metal and Al metal to make the Sc content reach 10at%; pump it to a vacuum of 8Pa, feed Ar gas to 0.04Mpa, and heat it to 1200°C through an induction furnace for smelting , turn off the power after heating for 3 hours, and use a water-cooled copper mold for casting.

[0044] (2) Heating the ingot in the step (1) to 600° C. under an Ar environment, and forging the ingot with a processing rate of 80%.

[0045] (3) subjecting the alloy in the step (2) to hot isostatic pressing at 640° C. and 150 MPa for 2 hours;

[0046] (4) machining the alloy in the step (3) into a diameter of 102mm, an aluminum-scandium alloy sputtering target with a thickness of 4mm;

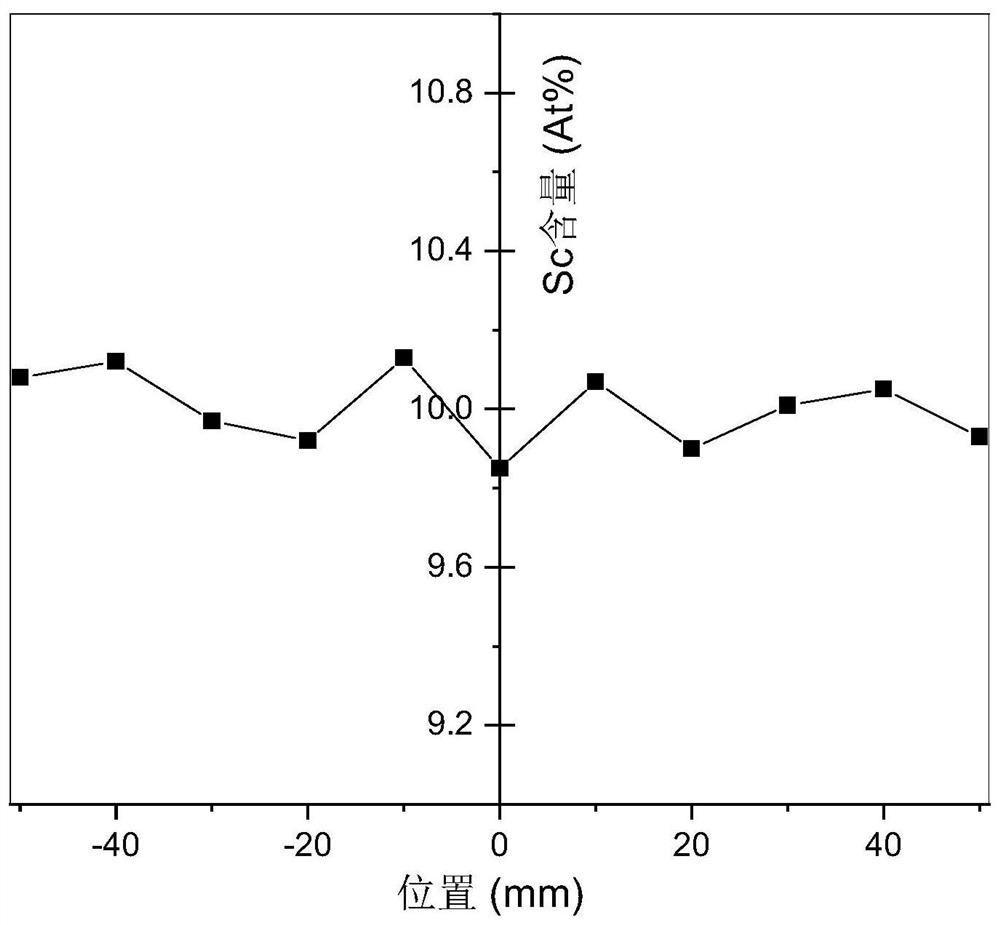

[0047] (5) Sampling the aluminum-scandium alloy sputtering target obtained in step...

Embodiment 2

[0051] In this embodiment, the preparation method of the aluminum scandium alloy sputtering target is carried out according to the following steps:

[0052] (1) Raw material smelting: In a vacuum intermediate frequency induction furnace, mix Sc metal and Al metal to make the Sc content reach 20at%; pump to vacuum to 6Pa, feed Ar gas to 0.07Mpa, and heat to 1280°C through induction furnace for smelting , turn off the power after heating for 3 hours, and use water-cooled iron molds for casting;

[0053] (2) heating the ingot in the step (1) to 1100° C. under an Ar environment, and forging the ingot, and the processing rate is 75%;

[0054] (3) subjecting the alloy in the step (2) to hot isostatic pressing for 3 hours at 1150°C and 180Mpa;

[0055] (4) machining the alloy in the step (3) into a diameter of 102mm, an aluminum-scandium alloy sputtering target with a thickness of 4mm;

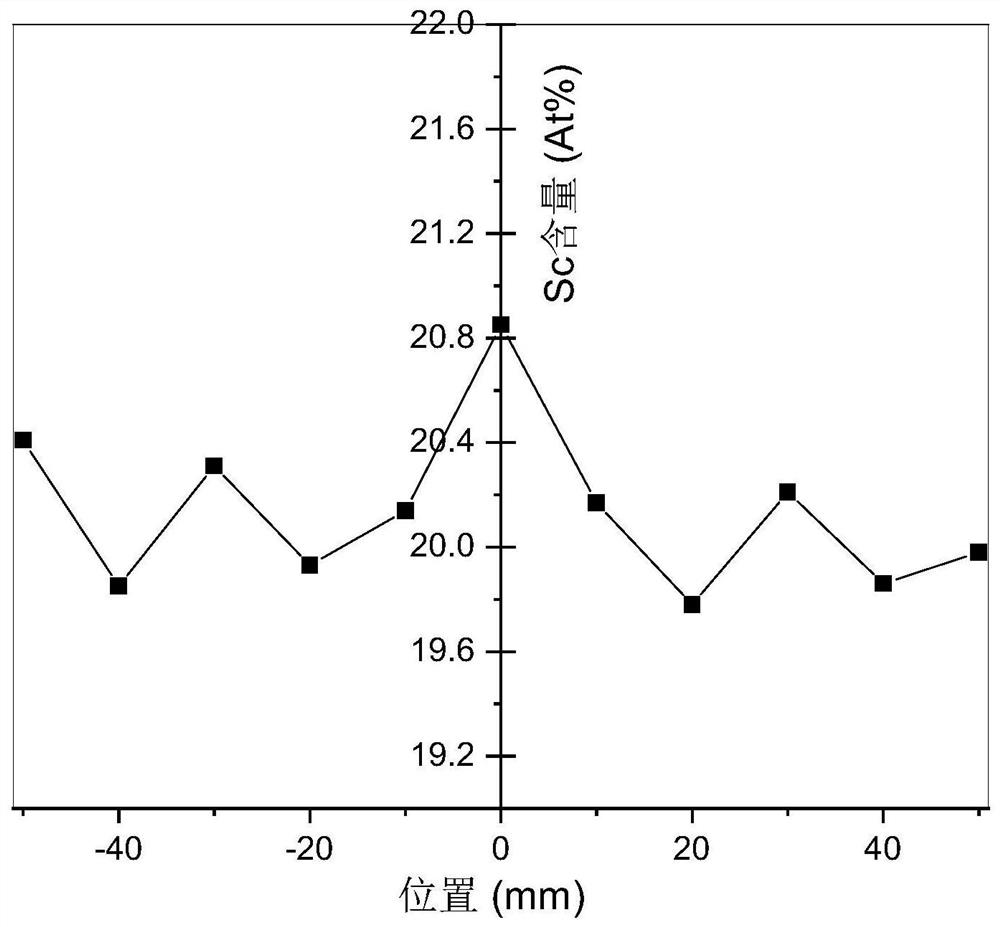

[0056] (5) Sampling the aluminum-scandium alloy sputtering target obtained in step 4, analyzing...

Embodiment 3

[0060] In this embodiment, the preparation method of the aluminum scandium alloy sputtering target is carried out according to the following steps:

[0061] (1) Raw material smelting: In a vacuum intermediate frequency induction furnace, mix Sc metal and Al metal to make the Sc content reach 30at%; evacuate to a vacuum of 4Pa, feed Ar gas to 0.06Mpa, and heat to 1400°C through an induction furnace for smelting , turn off the power after heating for 3 hours, and use graphite mold for casting.

[0062] (2) Heating the ingot in the step (1) to 1150° C. under an Ar environment, and forging the ingot with a processing rate of 75%.

[0063] (3) subjecting the alloy in the step (2) to hot isostatic pressing for 3 hours at 1150°C and 180Mpa;

[0064] (4) machining the alloy in the step (3) into a diameter of 102mm, an aluminum-scandium alloy sputtering target with a thickness of 4mm;

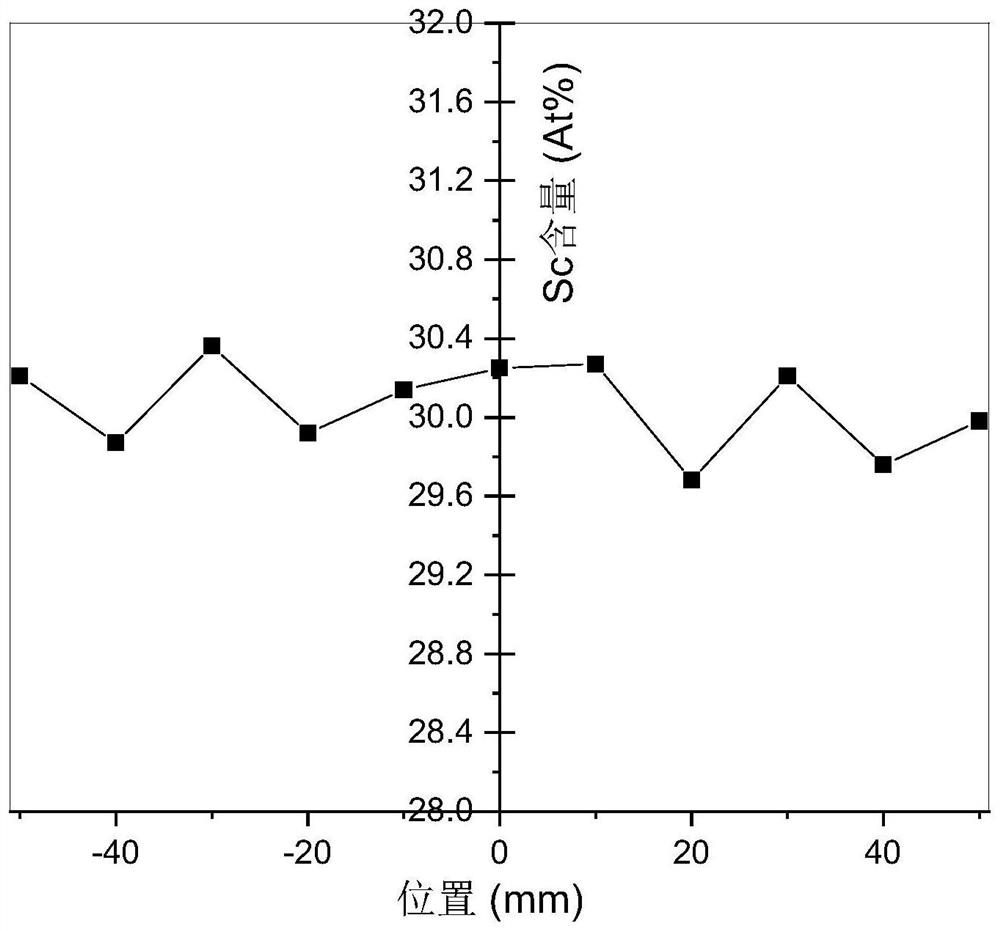

[0065] (5) Sampling the aluminum-scandium alloy sputtering target obtained in step 4, analyzing it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com