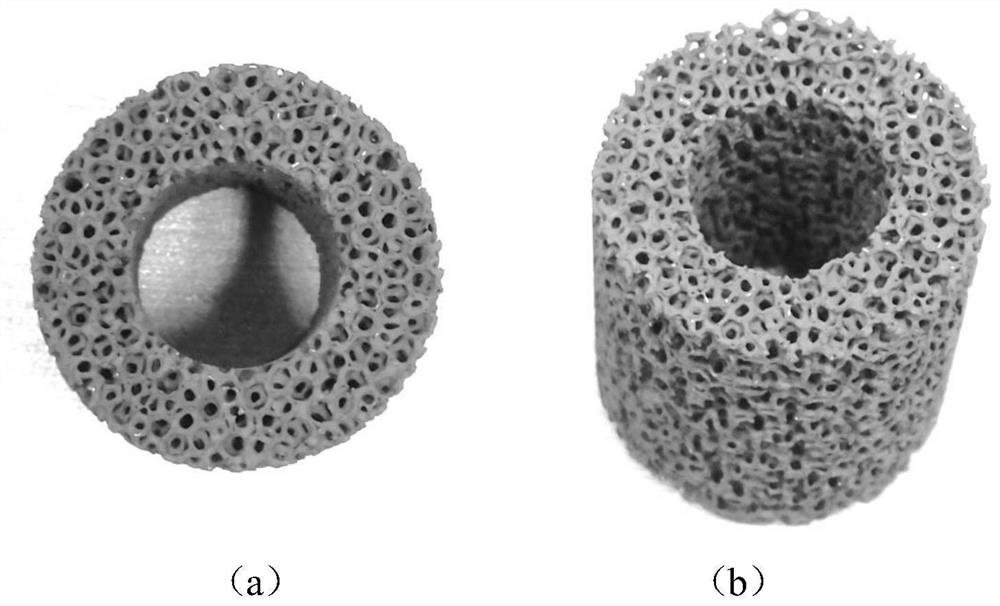

Silicon carbide random filler with porous structure, and preparation method thereof

A technology of porous silicon carbide and random packing, which is applied in the field of chemical packing, can solve the problems of accelerated corrosion of silicon-aluminum ceramics, unknown feasibility and cost performance, and no preparation technology route, so as to achieve good mass transfer efficiency and density The effect of small, well-developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, silicon carbide powder (average particle size 5 μm), phenolic resin, p-toluenesulfonic acid, and absolute ethanol were mixed in a weight ratio of 60:35:5:30, mechanically stirred, ball milled for 1 hour, and filtered. Obtain slurry raw material. The polyurethane foam with an average pore diameter of 2mm was dipped in the slurry and taken out, the slurry between the pores was blown away by compressed air, and then dried with hot air at 50°C for 20 minutes.

[0039]Cut the pre-dried polyurethane foam into long strips with a width of 10 mm and a thickness of 5 mm, and wind them in a spiral form on a metal rod coated with Teflon coating. When helically wound, the pitch is 10mm, which is consistent with the width of the polyurethane foam strip. The metal rod has a diameter of 15mm and a length of 1000mm. Heat the wrapped metal rod and polyurethane foam at 100°C to 120°C for 5 minutes to cure the resin.

[0040] After solidification, the metal rod was pull...

Embodiment 2

[0044] As described in Example 1, the difference is that the polyurethane foam is impregnated into the slurry and preliminarily dried, and then molded into a saddle-shaped, θ-shaped random packing.

Embodiment 3

[0046] The porous silicon carbide random packing as described in Example 1 was used to study its corrosion resistance in different media environments.

[0047] (1) Using HCl as the medium to study the corrosion resistance of the material. Configure three different concentrations of HCl acid solution (respectively 10wt%, 15wt%, 20wt%), take porous silicon carbide random packing and soak it in three kinds of different concentration solutions for 14 days, measure the mass change rate before and after, porous carbonization Silica random packing weight loss ≤ 0.2%, basically no corrosion;

[0048] (2) Using H 2 SO 4 As a medium, the corrosion resistance of the material was studied, and three different concentrations of H 2 SO 4 Acid solution (respectively 10wt%, 15wt%, 20wt%), take porous silicon carbide random packing and soak in three different concentration solutions for 14 days, measure the mass change rate before and after measurement, the weight loss of porous silicon car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com