Titanium dioxide ceramic material prepared by a sol-gel method

A ceramic material, titanium dioxide technology, applied in anodizing, ceramic products, metal material coating process and other directions, can solve the problems of poor compactness, corrosion resistance can not meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

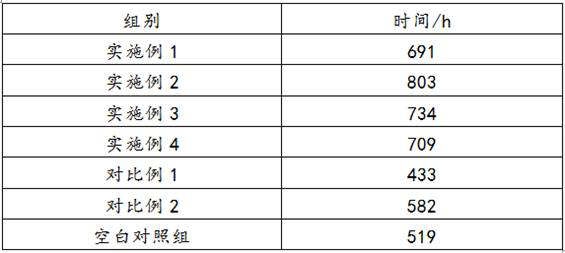

Examples

Embodiment 1

[0022] Sol-gel method prepares titanium dioxide ceramic material, comprises the following steps:

[0023] A. Using medical magnesium alloy as the substrate material, the magnesium alloy is cut into a size of 6×6×2mm;

[0024] B. Carry out pretreatment to magnesium alloy, and pretreatment includes degreasing, pickling, cleaning and drying, and wherein degreasing selects the sodium carbonate solution that concentration is 10%, and pickling selects concentration and is 15% hydrochloric acid solution, and cleaning process is anhydrous Ultrasonic cleaning with ethanol, drying under nitrogen atmosphere;

[0025] C. Preparation of micro-arc oxidation layer: with magnesium alloy as the anode, at 10A·dm -2 Under the conditions of constant current density, pulse frequency 450Hz, duty cycle 40%, termination voltage 400V, and time 10min, the magnesium alloy micro-arc oxidation layer was prepared, wherein the composition of the electrolyte was sodium hexametaphosphate 35g / L, hydrogen Pot...

Embodiment 2

[0031] Sol-gel method prepares titanium dioxide ceramic material, comprises the following steps:

[0032] A. Using medical magnesium alloy as the substrate material, the magnesium alloy is cut into a size of 6×6×2mm;

[0033] B. Carry out pretreatment to magnesium alloy, and pretreatment includes degreasing, pickling, cleaning and drying, and wherein degreasing selects the sodium carbonate solution that concentration is 10%, and pickling selects concentration and is 15% hydrochloric acid solution, and cleaning process is anhydrous Ultrasonic cleaning with ethanol, drying under nitrogen atmosphere;

[0034] C. Preparation of micro-arc oxidation layer: with magnesium alloy as the anode, at 10A·dm -2 Under the conditions of constant current density, pulse frequency 450Hz, duty cycle 40%, termination voltage 400V, and time 10min, the magnesium alloy micro-arc oxidation layer was prepared, wherein the composition of the electrolyte was sodium hexametaphosphate 35g / L, hydrogen Pot...

Embodiment 3

[0040] Sol-gel method prepares titanium dioxide ceramic material, comprises the following steps:

[0041] A. Using medical magnesium alloy as the substrate material, the magnesium alloy is cut into a size of 6×6×2mm;

[0042]B. Carry out pretreatment to magnesium alloy, and pretreatment includes degreasing, pickling, cleaning and drying, and wherein degreasing selects the sodium carbonate solution that concentration is 10%, and pickling selects concentration and is 15% hydrochloric acid solution, and cleaning process is anhydrous Ultrasonic cleaning with ethanol, drying under nitrogen atmosphere;

[0043] C. Preparation of micro-arc oxidation layer: with magnesium alloy as the anode, at 10A·dm -2 Under the conditions of constant current density, pulse frequency 450Hz, duty cycle 40%, termination voltage 400V, and time 10min, the magnesium alloy micro-arc oxidation layer was prepared, wherein the composition of the electrolyte was sodium hexametaphosphate 35g / L, hydrogen Pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com