Composite material interlayer for battery as well as preparation method and application of composite material interlayer

A composite material and interlayer technology, applied in the field of composite materials, can solve the problems of lithium dendrites with fast migration of lithium ions, uneven temperature distribution of lithium-sulfur batteries, local temperature, persulfide shuttle, etc., to improve mechanical properties and improve electrochemical performance. Reaction rate, the effect of promoting electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A kind of preparation method of composite material interlayer for battery provided by the invention comprises the following steps:

[0047] (1) Dissolving the catalytic material precursor in the aqueous solution of graphene oxide, stirring to obtain a uniformly dispersed graphene oxide-catalytic material precursor mixed dispersion;

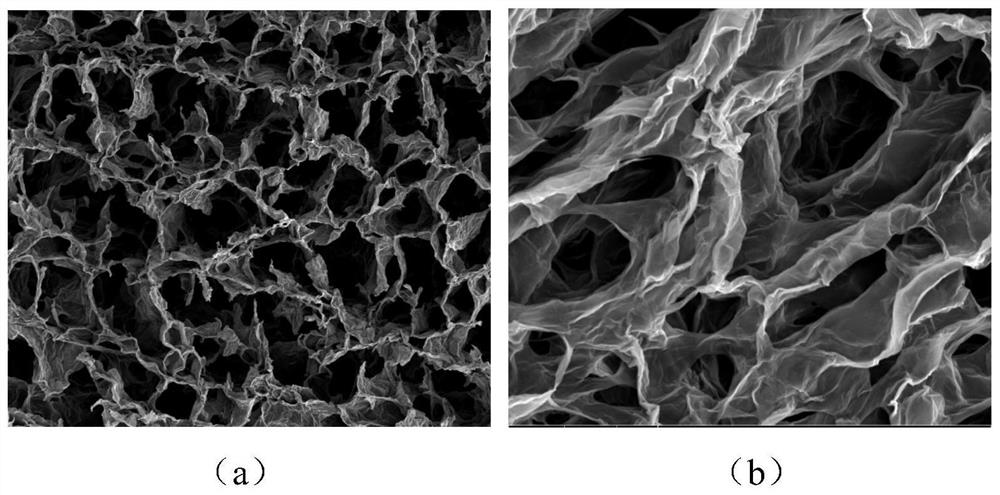

[0048] (2) The graphene oxide-catalyzed material precursor mixed dispersion obtained in step (1) is prepared by the ice template method to obtain the graphene oxide / catalyzed material precursor aerogel;

[0049] (3) heat-treating the graphene oxide / catalytic material precursor aerogel obtained in step (2) under a protective atmosphere to obtain graphene / catalytic material aerogel;

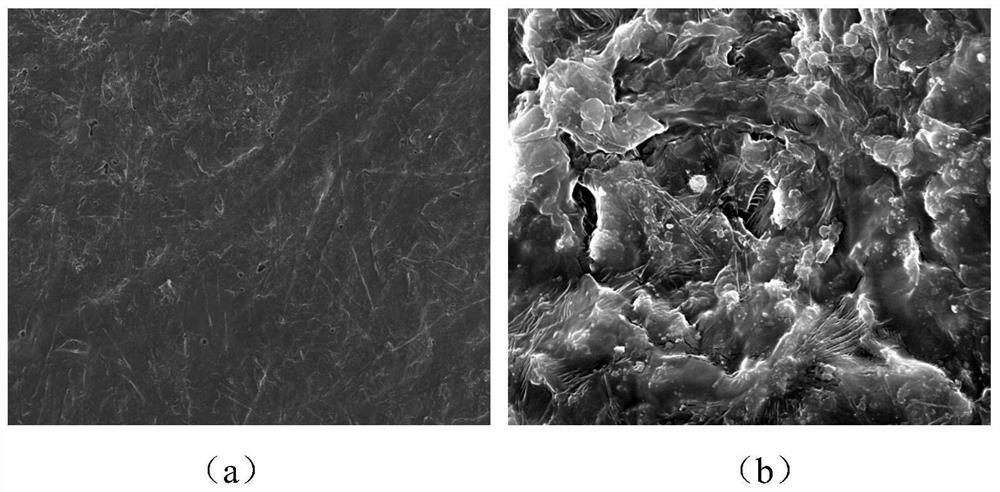

[0050] (4) the organic solution of macromolecule material is perfused in the Graphene / catalyst material aerogel that step (3) obtains, makes the pore of the Graphene / catalyst material aerogel that step (3) obtains be covered by macromolecule material The organi...

Embodiment 1

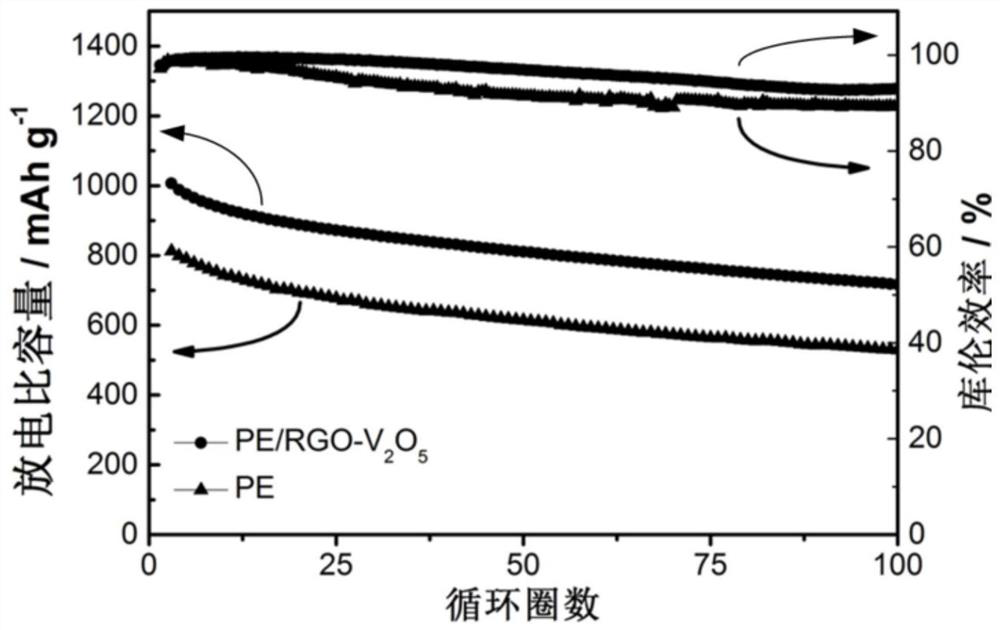

[0067] A composite material interlayer with heat conduction and catalytic functions, the composite material interlayer is a polyethylene oxide / graphene / vanadium pentoxide composite interlayer with a thickness of 5 μm; wherein the graphene has a honeycomb airgel network structure, and vanadium pentoxide is dispersed in the honeycomb airgel network structure; the polyethylene oxide is filled in the pores of the honeycomb airgel network structure; polyethylene oxide, graphene and The mass ratio of vanadium pentoxide is 90:2:8; the relative molecular mass of polyethylene oxide is 100,000.

[0068] The preparation method of the composite interlayer with heat conduction and catalytic functions comprises the following steps:

[0069](1) 1g ammonium metavanadate is dissolved in 0.1L concentration and is the aqueous solution of graphene oxide of 10g / L, through 1h ultrasonic stirring, obtains the graphene oxide-ammonium metavanadate mixed dispersion liquid of uniform dispersion;

[007...

Embodiment 2

[0076] A composite interlayer with heat conduction and catalytic functions, the composite interlayer is a polyethylene oxide / graphene / molybdenum disulfide composite interlayer with a thickness of 5 μm, wherein the graphene has a honeycomb airgel network structure, and Molybdenum disulfide is dispersed in the honeycomb airgel network structure; polyethylene oxide is filled in the pores of the honeycomb airgel network structure; the mass ratio of polyethylene oxide, graphene and molybdenum disulfide It is 90:5:5; the relative molecular mass of polyethylene oxide is 100,000.

[0077] The preparation method of the composite interlayer with heat conduction and catalytic functions comprises the following steps:

[0078] (1) 1g ammonium tetrathiomolybdate is dissolved in 0.1L concentration and is the aqueous solution of the graphene oxide of 10g / L, through 1h ultrasonic stirring, obtains the graphene oxide-ammonium tetrathiomolybdate mixed dispersion liquid uniformly dispersed;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com