Expansion type nanometer inhibition gel for inhibiting spontaneous combustion of coal and preparation method of expansion type nanometer inhibition gel

An intumescent flame retardant and intumescent technology, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of inability to improve material performance and decline in material performance, and achieve good water retention performance, Effect of reducing heat release and heat release rate and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

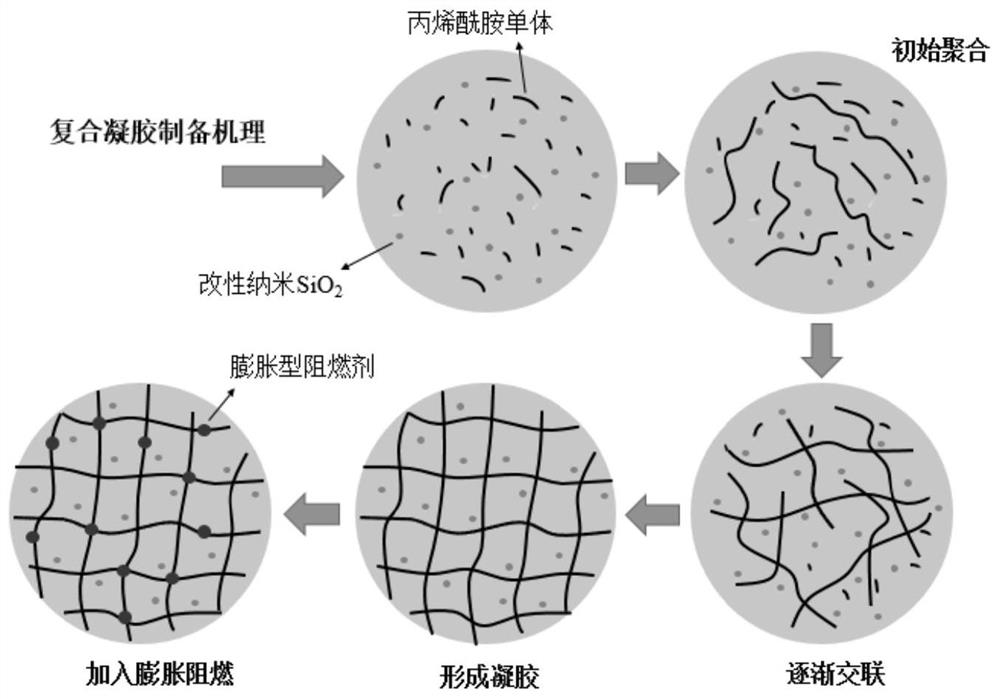

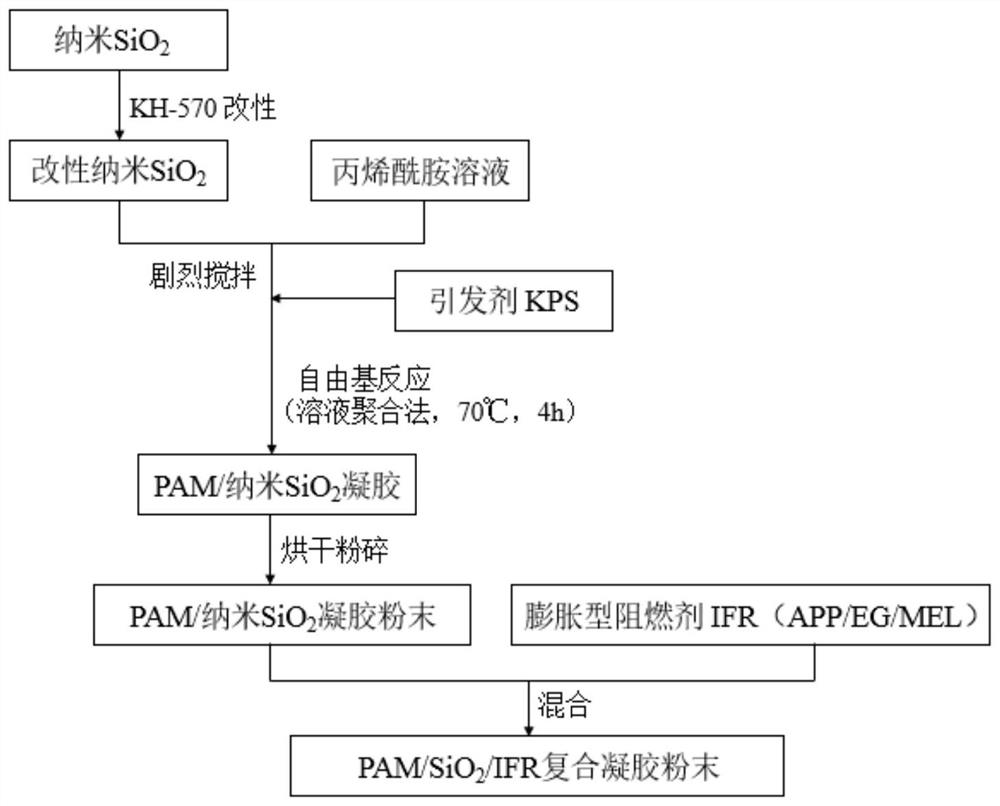

[0047] The present invention compound modified nano-silica and polyacrylamide gel, prepare modified nano-silica / polyacrylamide composite gel, and find the best compounding of modified nano-silica / polyacrylamide Ratio, in order to achieve the optimal effect of inhibitor inhibition.

[0048] Modified nano-silica / polyacrylamide composite, we use solution polymerization method, acrylamide is monomer, initiator potassium persulfate. According to the central combination design principle of Box-Benhnkende, the reaction temperature (A) the amount of modified nano-silica, (B) the amount of initiator potassium persulfate, and (C) three factors that have a significant impact on the inhibitory effect of the inhibitor are selected. Adopting 3-factor and 3-level response surface analysis method, the design experimental points include 12 factorial design points and 5 calibration zero points. According to experimental results and experience, the value range of the amount of modified nano-sil...

Embodiment 2

[0058] Experimental comparative analysis of microstructure and morphology of swelling nano-barrier gel

[0059] (1) Sample preparation

[0060] Configure intumescent flame retardant / modified nano-silica / polyacrylamide composite gel (the present invention), modified nano-silica / polyacrylamide composite gel, pure polyacrylamide gel, grind after drying Before, block samples were taken for gold spraying treatment.

[0061] (2) Equipment parameters

[0062] Using ZEISS Gemini SEM 500 scanning electron microscope (SEM) system, under the condition of 30.00kV, different magnifications were used to observe the micro-morphological characteristics of the inhibitor.

[0063] (3) Research and analysis of microstructure morphology

[0064] image 3 (a) is the microscopic SEM of intumescent flame retardant / modified nano silicon dioxide / polyacrylamide composite gel (the present invention), image 3 (b) is a microscopic SEM of the modified nano-silica / polyacrylamide composite gel, image...

Embodiment 3

[0066] Comparative analysis of thermogravimetric experiments on the inhibition of spontaneous combustion of coal by intumescent nano-resistance gel

[0067] (1) Sample preparation

[0068] Coal powder with a particle size of 80-120 mesh (0.124-0.178mm) was used as the raw coal sample, and the intumescent nanogel was prepared according to the optimization result of the response surface analysis method, and the raw coal sample was processed. Put 15g of coal samples sieved through 140 mesh into 4 same 300ml beakers, add 35ml water to the first beaker, which is recorded as sample 1; add 35ml pure polyacrylamide gel to the second beaker, which is recorded as Sample 2; add 35ml of modified nano-silica / polyacrylamide gel to the third one, denoted as sample 3; add 35ml of intumescent flame retardant / modified nano-silica / polyacrylamide to the fourth one Composite gel (invention), designated as sample 4. Stir evenly, let it fully react for 24 hours, dry it naturally or dry it in an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com