A kind of preparation method of environment-friendly algae-removing coagulant

An environmentally friendly, coagulant technology, applied in the field of environmental governance, can solve the problems of consuming dissolved oxygen, easily clogged membrane pores, and increased treatment costs of water plants, achieving low water pollution and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

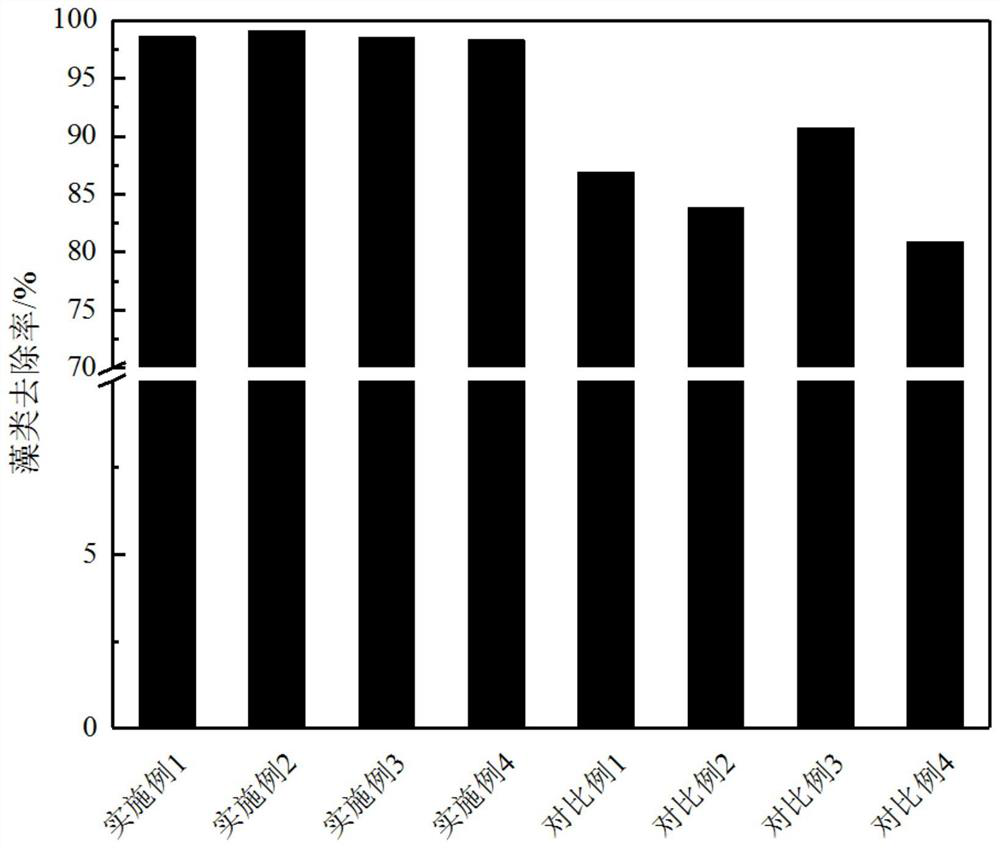

Image

Examples

Embodiment 1

[0022] An environment-friendly algae-removing coagulant, the preparation method of which is:

[0023] (1) Aluminum chloride hexahydrate powder, ferric chloride hexahydrate powder, and cerium trichloride hexahydrate powder are respectively ground and passed through a 500-mesh sieve, and aluminum chloride hexahydrate and chlorine hexahydrate after sieving are weighed. Ferric chloride, cerium trichloride hexahydrate powder, three kinds of sieved powders are mixed evenly in the ratio of aluminum chloride hexahydrate by mass: ferric chloride hexahydrate: cerium trichloride hexahydrate=1:1:0.3 Finally, heat to 250°C for a roasting, the roasting time is 20min, after the roasting is completed, air cool to normal temperature, and then add iridium trichloride powder to the powder, the blending quality of the iridium trichloride powder is chlorinated hexahydrate in the powder 1 / 18 times the mass of aluminum, stir the powder evenly, heat again to 180°C for secondary roasting, the roasting...

Embodiment 2

[0027] An environment-friendly algae-removing coagulant, the preparation method of which is:

[0028] (1) Aluminum chloride hexahydrate powder, ferric chloride hexahydrate powder, and cerium trichloride hexahydrate powder were ground respectively and passed through a 500-mesh sieve, and the sieved aluminum chloride hexahydrate and hexahydrate Ferric chloride, cerium trichloride hexahydrate powder, three kinds of sieved powders are mixed by mass ratio aluminum chloride hexahydrate: ferric chloride hexahydrate: cerium trichloride hexahydrate=1:1:0.4 After uniformity, heat to 270 ° C for a roasting time of 18 minutes. After the roasting is completed, air cool to room temperature, and then add iridium trichloride powder to the powder. 1 / 18 times the mass of aluminum chloride, stir the powder evenly, heat again to 190°C for a second roasting, the roasting time is 30min; after the roasting is completed, air cool to room temperature;

[0029] (2) Pour the powder processed in the ste...

Embodiment 3

[0032] An environment-friendly algae-removing coagulant, the preparation method of which is:

[0033] (1) Aluminum chloride hexahydrate powder, ferric chloride hexahydrate powder, and cerium trichloride hexahydrate powder were ground respectively and passed through a 500-mesh sieve, and the sieved aluminum chloride hexahydrate and hexahydrate Ferric chloride, cerium trichloride hexahydrate powder, three kinds of sieved powders are mixed in the ratio of aluminum chloride hexahydrate by mass: ferric chloride hexahydrate: cerium trichloride hexahydrate=1:2:0.5 After uniformity, heat to 290 ° C for a roasting time of 15 minutes. After the roasting is completed, air cool to room temperature, and then add iridium trichloride powder to the powder. 1 / 18 times the mass of aluminum chloride, stir the powder evenly, heat again to 190°C for secondary roasting, the roasting time is 30min; air cool to room temperature after the roasting is completed;

[0034] (2) Pour the powder processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com