Steel structure house anti-corrosion treatment process

A treatment process and anti-corrosion technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problem that the comprehensive performance is difficult to meet the requirements of use, cannot be placed in a humid environment for a long time, and has poor water resistance and salt spray resistance. problem, to achieve the effect of excellent salt spray resistance, comprehensive performance improvement, rapid and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

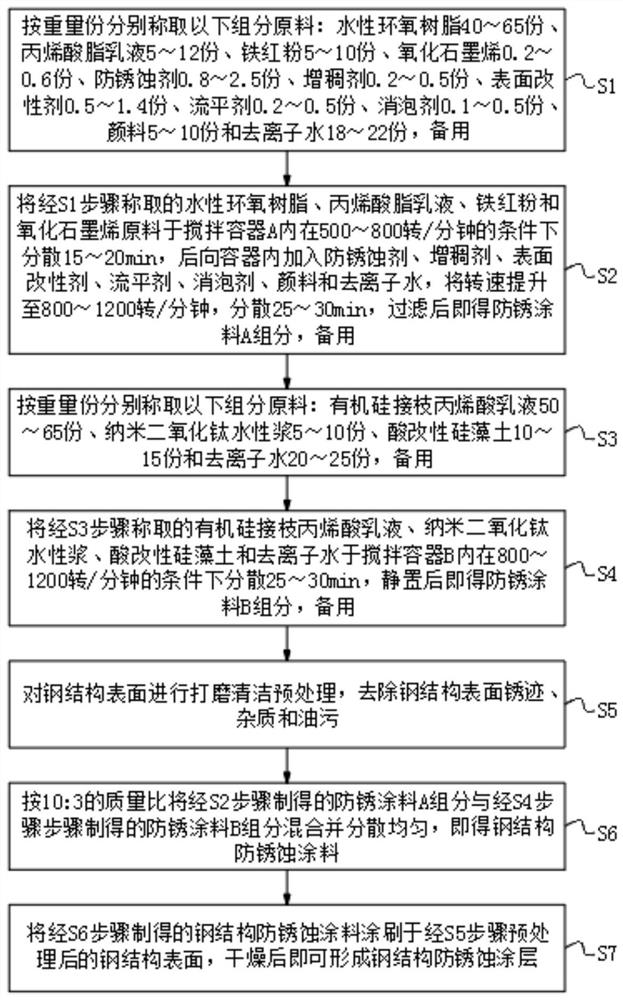

[0030] see Figure 1-2 , the present invention provides the following technical solutions: a steel structure residential anti-corrosion treatment process, including the following treatment steps:

[0031] Step S1. Weigh the following component A raw materials by weight: 52 parts of water-based epoxy resin; 8 parts of acrylic emulsion, 7 parts of iron red powder, 0.5 parts of graphene oxide, 1.5 parts of high-efficiency flash rust inhibitor, gas phase dioxide 0.3 parts of silicon, 1 part of Z-6040 epoxy silane coupling agent, 0.3 parts of BYK-346 leveling agent, 0.4 parts of BYK-024 defoamer, 7 parts of titanium dioxide and 21 parts of deionized water, set aside;

[0032] Step S2, disperse the water-based epoxy resin, acrylate emulsion, iron red powder and graphene oxide raw materials weighed in step S1 in a stirring container at 600 rpm for 18 minutes, and then add a high-efficiency flash rust inhibitor into the container , fumed silica, Z-6040 epoxy silane coupling agent, BY...

Embodiment 2

[0040] see Figure 1-2 , the present invention provides the following technical solutions: a steel structure residential anti-corrosion treatment process, including the following treatment steps:

[0041] Step S1. Weigh the following component A raw materials by weight: 40 parts of water-based epoxy resin; 12 parts of acrylate emulsion, 10 parts of iron red powder, 0.6 parts of graphene oxide, 2.5 parts of modified sulfonic acid sodium salt inhibitor, 0.5 parts of cellulose ether thickener, 1.4 parts of Z-6040 epoxy silane coupling agent, 0.5 parts of BYK-346 leveling agent, 0.5 parts of BYK-024 defoamer, 10 parts of kaolin and 22 parts of deionized water, spare;

[0042] Step S2, disperse the water-based epoxy resin, acrylate emulsion, iron red powder and graphene oxide raw materials in the stirring container at 500 rpm for 15 minutes, and then add modified sodium sulfonate to the container Salt inhibitor, cellulose ether thickener, Z-6040 epoxy silane coupling agent, BYK-3...

Embodiment 3

[0050] see Figure 1-2 , the present invention provides the following technical solutions: a steel structure residential anti-corrosion treatment process, including the following treatment steps:

[0051] Step S1. Weigh the following component A raw materials by weight: 65 parts of water-based epoxy resin; 5 parts of acrylate emulsion, 5 parts of iron red powder, 0.2 part of graphene oxide, 0.8 part of high-efficiency flash rust inhibitor, hydrogenated castor oil 0.2 parts, 0.5 parts of Z-6040 epoxy silane coupling agent, 0.2 parts of BYK-346 leveling agent, 0.1 parts of BYK-024 defoamer, 5 parts of quartz powder and 18 parts of deionized water, set aside;

[0052] Step S2, disperse the water-based epoxy resin, acrylate emulsion, iron red powder and graphene oxide raw materials weighed in step S1 in a stirring container at 800 rpm for 15 minutes, and then add a high-efficiency flash rust inhibitor into the container , hydrogenated castor oil, Z-6040 epoxy silane coupling agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com