Antistatic anti-aging polyimide explosion-proof membrane

A polyimide and anti-static technology, applied in the field of anti-static and anti-aging polyimide explosion-proof film, can solve the problems of improving the anti-static performance and anti-aging performance of explosion-proof film, and being unable to apply to folding screens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of explosion-proof film is:

[0036] (1) Weigh high-functionality urethane acrylate, antistatic flexible anti-aging agent, reactive diluent, photoinitiator, nanoparticles, anti-fingerprint agent and solvent in proportion, first disperse the nanoparticles in the solvent, grind them evenly, and then Add the remaining components and disperse evenly to obtain a hardening solution;

[0037] (2) uniformly coating the hardening solution prepared in step (1) on the polyimide film, then thermally drying to volatilize the solvent;

[0038] (3) Carry out UV curing, stick the protective film, and cut it as required.

Embodiment 1

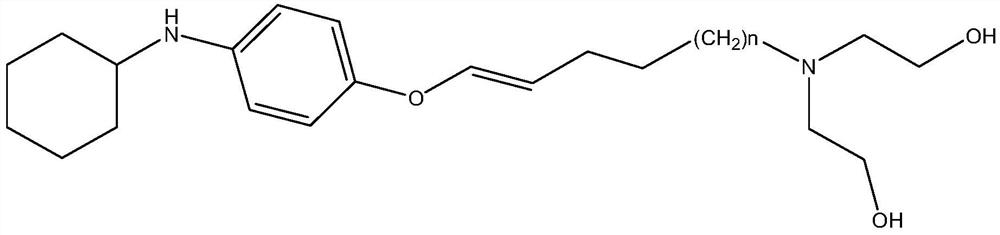

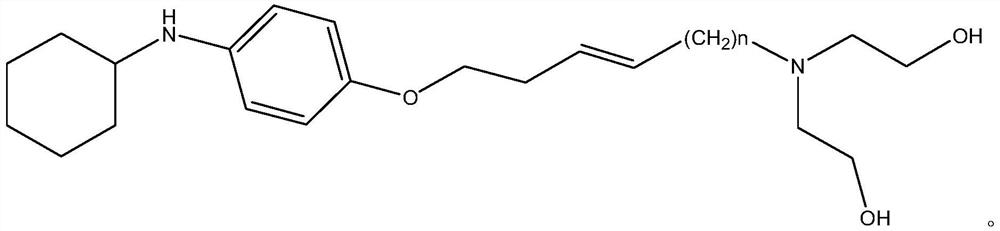

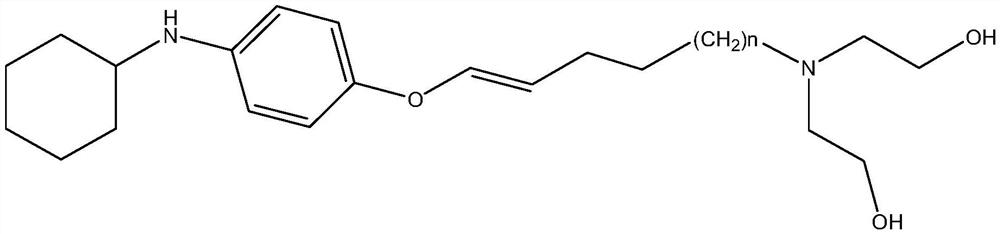

[0040] (1) Weigh 40 parts of Etercure6145-100 (6 grades) of Changxing Chemical, 40 parts of Etercure6150-100 (6 grades) of Changxing Chemicals, 15 parts of antistatic flexible anti-aging agent (n=15), 5 parts of tripropylene glycol Diacrylate, 5 parts of trimethylolpropane triacrylate, 1 part of phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide, 10 parts of silane coupling agent KH-570 modified nano Silicon dioxide, 0.05 parts of anti-fingerprint agent, 40 parts of methyl ethyl ketone, 40 parts of isopropanol, first add the nano-silica modified by silane coupling agent KH-570 into the solvent and grind it evenly, then add the rest of the components Divide and disperse evenly to obtain hardening solution;

[0041] (2) Evenly coat the hardening solution on the polyimide film, and dry at 80-85°C for 7 minutes to evaporate the solvent;

[0042] (3) according to the illuminance 300mW / cm 2 , light intensity 600mJ / cm 2 , The film surface temperature is 40 ℃ UV curing conditions f...

Embodiment 2

[0044] (1) Weigh 60 parts of Etercure6150-100 (6 parts) of Changxing Chemical, 30 parts of Etercure_DR-U591 (10 parts) of Changxing Chemical, 20 parts of antistatic flexible anti-aging agent (n=14), 10 parts of tripropylene glycol Diacrylate, 5 parts of isobornyl methacrylate, 1 part of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, 1 part of 2,4,6-trimethylbenzoyl di Phosphine phenoxide, 10 parts of nano silicon dioxide modified by silane coupling agent KH-570, 6 parts of nano titanium dioxide modified by silane coupling agent KH-570, 0.4 part of anti-fingerprint agent, 60 parts of propylene glycol monomethyl ether, 40 parts 1 part of n-butyl acetate, 20 parts of methyl ethyl ketone, first add nano-silica modified by silane coupling agent KH-570 and nano-titanium dioxide modified by silane coupling agent KH-570 into the solvent and grind evenly, and then add the remaining components Divide, disperse evenly to obtain hardening solution;

[0045] (2) Evenly coat the hardeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com