Halogen-free flame-retardant reinforced polyamide composite material and preparation method and application thereof

A composite material and polyamide technology, which is applied in the field of halogen-free flame-retardant reinforced polyamide composite materials and its preparation, can solve the problems of lower flame-retardant efficiency than MPP, low flame-retardant synergistic effect, and increased corrosion effect, and achieve outstanding chemical resistance Corrosion, high stability, outstanding effect of physical abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

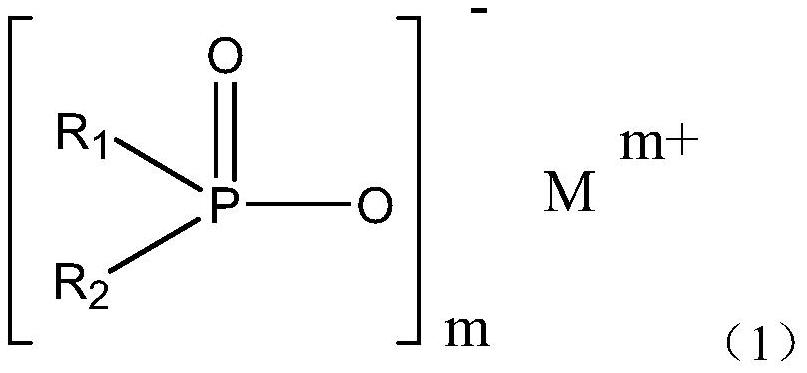

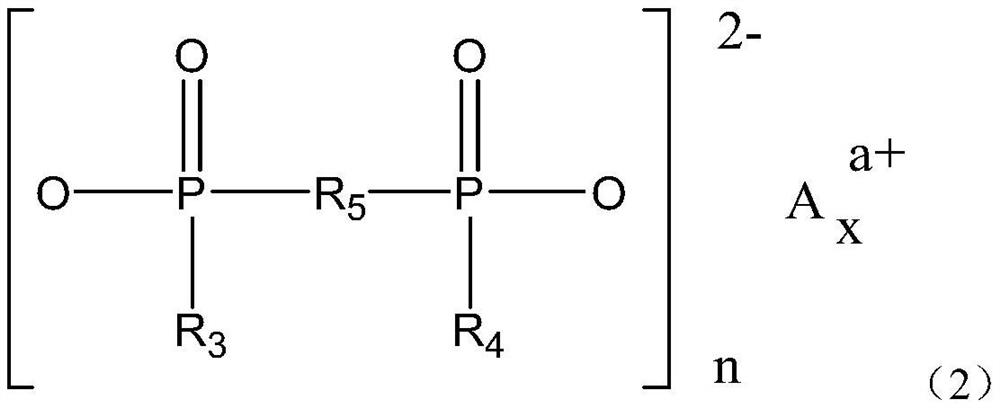

Method used

Image

Examples

Embodiment Construction

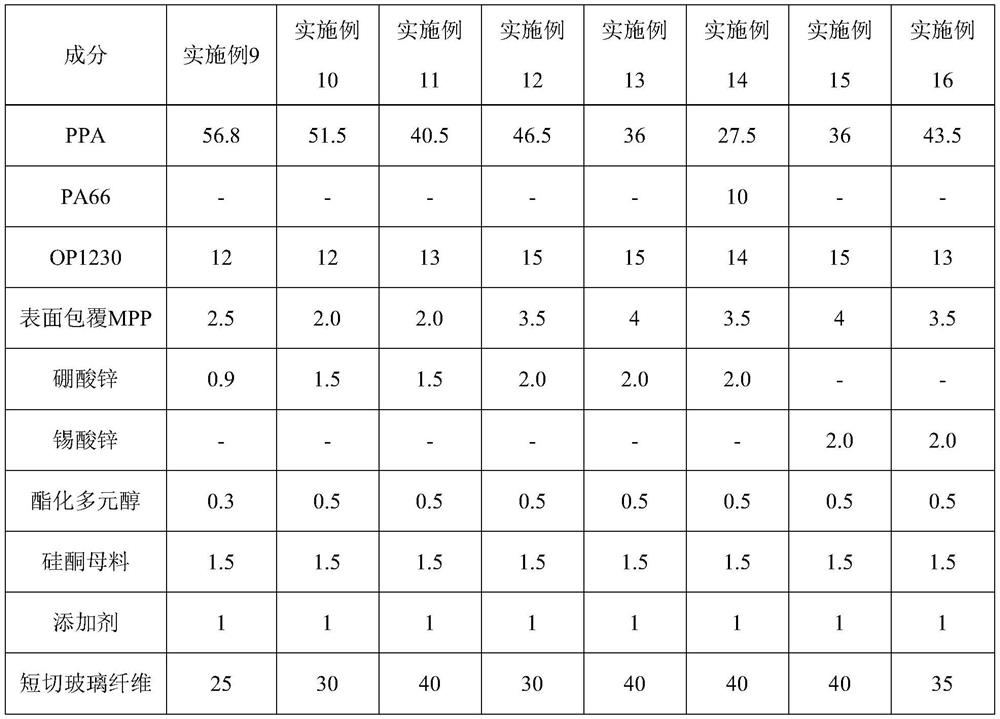

[0074] The content of the present invention will be described in further detail below through specific examples. The raw materials, reagents or devices used in the examples and comparative examples can be obtained from conventional commercial channels or obtained by prior art methods unless otherwise specified. Unless otherwise specified, experiments or testing methods are conventional methods in the art.

[0075] The raw materials adopted in the following examples are described as follows:

[0076] Polyamide resin: PA66 grade is A27, provided by BASF, Germany; PPA grade is HTplus M1000, provided by Evonik, Germany;

[0077] Organic hypophosphite is provided by Clariant, Germany, and its commercial grade is OP1230;

[0078] MPP for BASF 200;

[0079] Zinc borate supplied to Sanxiang (Borax) in the United States 500;

[0080] Zinc stannate is provided by Wembola Co., Ltd. of the United Kingdom, and its commercial grade is S;

[0081] The esterified polyol is prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com