Processing and production method of anticorrosive latex paint

A production method and technology of latex paint, applied in the field of latex paint, can solve the problems of interface compatibility between inorganic zinc and organic raw materials, difficulty in significantly improving anti-corrosion performance, and difficulty in significantly improving material corrosion resistance, so as to improve hydrophobic effect, The effect of stabilizing the system and improving the degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

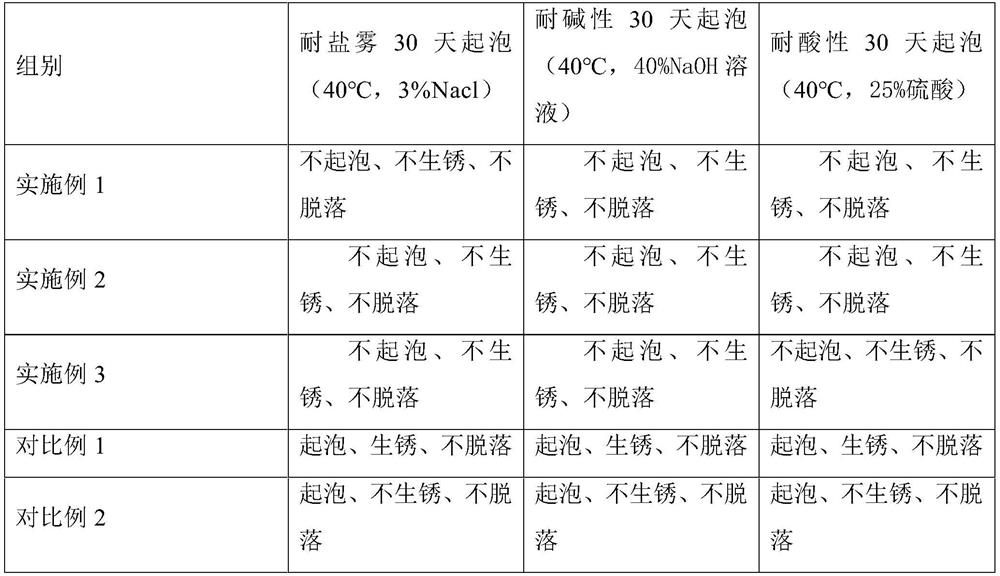

Examples

Embodiment 1

[0028] A kind of processing production method of anticorrosion latex paint of the present embodiment, comprises the following steps:

[0029] Step 1, the preparation of modified zinc oxide powder:

[0030] S1: Pre-calcine 40 parts of zinc oxide for 15 minutes at a pre-calcination temperature of 350°C, then cool to 65°C and keep warm for later use;

[0031] S2: Then add 10 parts of polyethylene glycol to 100 parts of ethanol solution, first stir at a speed of 100r / min for 255min, then add 30 parts of isophorone diisocyanate, and then add 1 part of organotin catalyst , get modifier;

[0032] S3: Add the heat-preserved zinc oxide into the modifier, then stir at a speed of 1500r / min for 25min at a stirring temperature of 105°C, then add 20 parts of aspartic acid with a molar concentration of 0.5 mol / L boric acid solution, and continue Stir for 20 minutes, finally wash with water, filter, and centrifuge to obtain modified zinc oxide powder;

[0033] Step 2, weighing of raw mater...

Embodiment 2

[0044] A kind of processing production method of anticorrosion latex paint of the present embodiment, comprises the following steps:

[0045] Step 1, the preparation of modified zinc oxide powder:

[0046] S1: Pre-calcine 50 parts of zinc oxide for 25 minutes at a temperature of 450°C, then cool to 75°C and keep it warm for later use;

[0047] S2: Then add 20 parts of polyethylene glycol to 200 parts of ethanol solution, first stir at a speed of 200r / min for 35 minutes, then add 40 parts of isophorone diisocyanate, and then add 5 parts of organotin catalyst , get modifier;

[0048] S3: Add the heat-preserved zinc oxide into the modifier, then stir at a speed of 250r / min for 35min at a stirring temperature of 115°C, then add 30 parts of aspartic acid with a molar concentration of 0.9 mol / L boric acid aqueous solution, and continue Stir for 30 minutes, finally wash with water, filter, and centrifuge to obtain modified zinc oxide powder;

[0049] Step 2, weighing of raw materi...

Embodiment 3

[0060] A kind of processing production method of anticorrosion latex paint of the present embodiment, comprises the following steps:

[0061] Step 1, the preparation of modified zinc oxide powder:

[0062] S1: 45 parts of zinc oxide were pre-calcined for 20 minutes at a pre-calcination temperature of 400°C, then cooled to 70°C, and kept warm for later use;

[0063] S2: Then add 15 parts of polyethylene glycol to 150 parts of ethanol solution, first stir at a speed of 150r / min for 30min, then add 35 parts of isophorone diisocyanate, and then add 3 parts of organotin catalyst , get modifier;

[0064] S3: Add the heat-preserved zinc oxide into the modifier, then stir at a speed of 200r / min for 30min at a stirring temperature of 110°C, then add 25 parts of aspartic acid with a molar concentration of 0.7 mol / L boric acid aqueous solution, and continue Stir for 25 minutes, finally wash with water, filter, and centrifuge to obtain modified zinc oxide powder;

[0065] Step 2, weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com