Two-photon parallel direct writing device and method based on multi-dot matrix generation and independent control

An independent control, two-photon technology, applied in photoplate-making process exposure devices, optics, optomechanical equipment, etc., can solve the problems of low processing throughput, poor uniformity, manufacturing difficulty and cost increase, and achieve high processing throughput. , high gray level, flexible processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

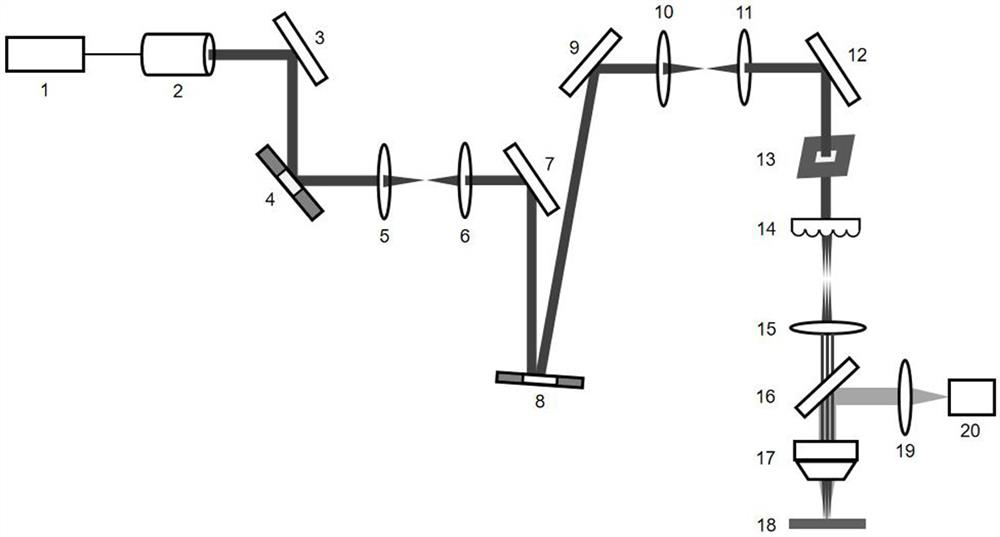

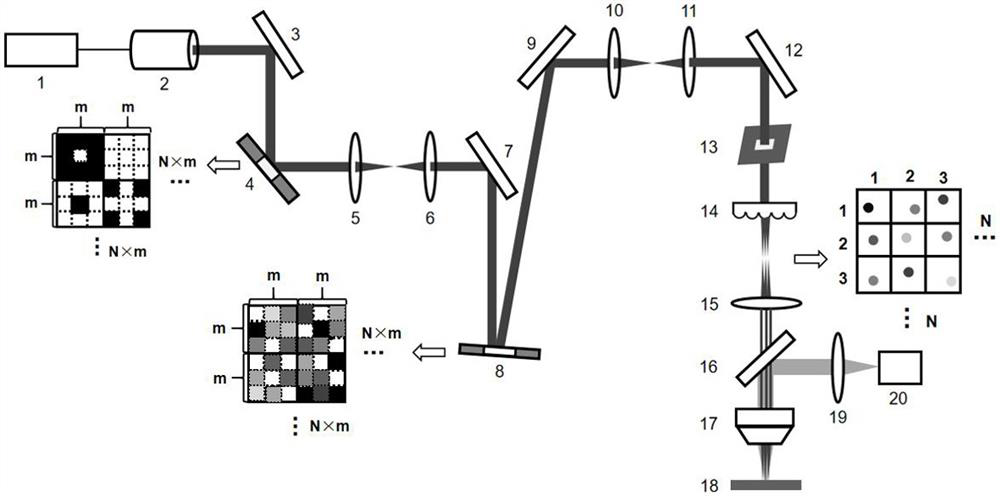

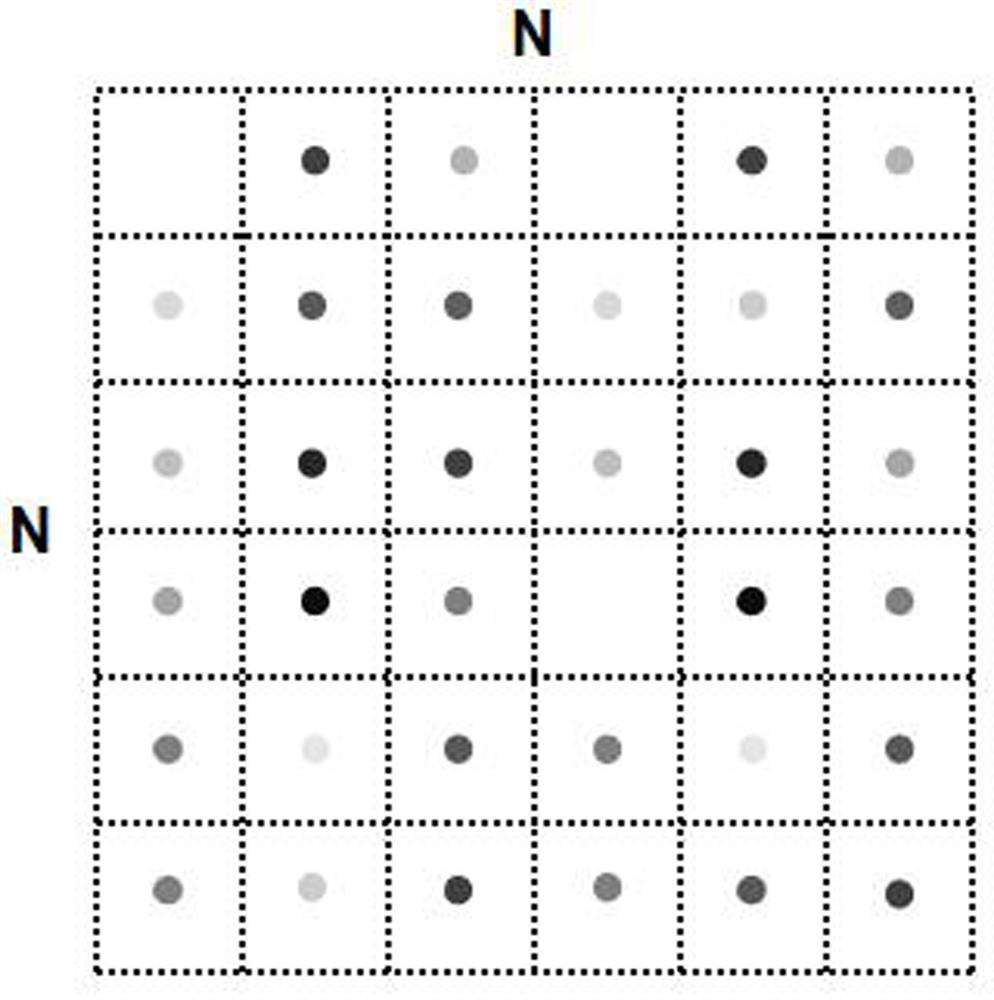

[0027] Such as figure 1 As shown, the present invention provides a two-photon parallel direct writing device for multi-lattice generation and independent control, which includes a femtosecond laser pulse 1, a beam expander 2, a first mirror 3, Digital micromirror array DMD4, first convex lens 5, second convex lens 6, second mirror 7, spatial light modulator SLM8, third mirror 9, third convex lens 10, fourth convex lens 11, fourth mirror 12, Square adjustable diaphragm 13 , microlens array MLA14 , fifth convex lens 15 , dichroic mirror 16 , objective lens 17 , precision displacement stage 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com