Polyimide double-sided flexible heat-conducting copper-clad plate as well as preparation method and application thereof

A technology of polyimide and copper clad laminate, applied in the field of polyimide double-sided flexible thermal conductive copper clad laminate and its preparation, can solve the problems of mechanical properties decline of composite materials, inability to meet requirements, etc., and achieve peel strength and heat resistance. The effect of good performance and efficient thermal conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

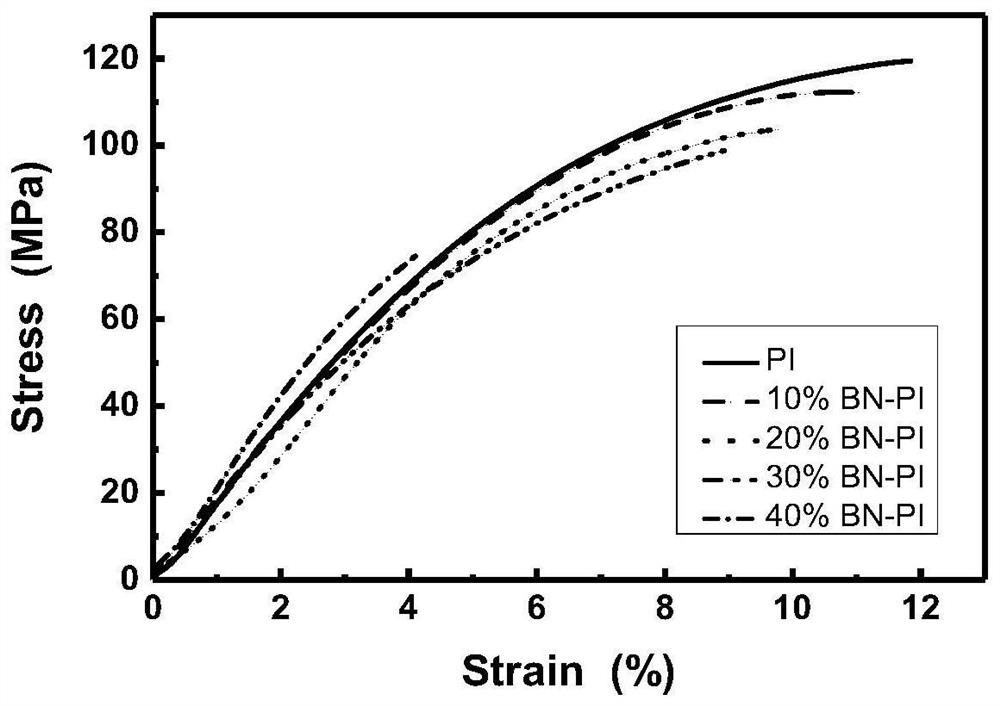

[0055] This example provides four kinds of polyimide composite films (h-BN@DMY-200°C / PI composite film) containing different contents of dihydromyricetin modified hexagonal boron nitride microsheets, and combined with pure polyimide Comparison of imide films to determine the optimal addition amount of dihydromyricetin-modified hexagonal boron nitride microsheets in polyimide double-sided flexible thermally conductive copper clad laminates.

[0056] The preparation method of polyimide composite film is as follows:

[0057] S1. Ultrasonic disperse 100 parts of hexagonal boron nitride (h-BN) in 1000 parts of dihydromyricetin-ethanol solution with a mass concentration of 50 mg / ml, stir and react at room temperature for 24 hours, filter, and vacuum dry at 70°C for 12 hours. Dihydromyricetin-modified hexagonal boron nitride microsheets (h-BN@DMY) were obtained, and h-BN@DMY was heat-treated at 200°C for 4 hours to obtain dihydromyricetin-modified hexagonal boron nitride microsheets ...

Embodiment 2

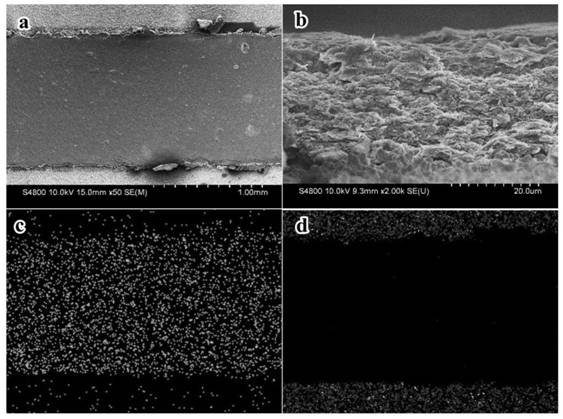

[0061] This embodiment provides a polyimide double-sided flexible heat-conducting copper-clad laminate. The preparation method of the polyimide double-sided flexible heat-conducting copper-clad laminate is as follows:

[0062] S1. Preparation of sodium cholate modified hexagonal boron nitride nanosheets (BNNS@SC):

[0063] Weigh 2 parts of hexagonal boron nitride powder and place it in a zirconia ball mill jar, add 10 parts of sodium cholate aqueous solution (0.1%) and 68 parts of zirconia balls, and ball mill for 12 hours at 200 rpm. Use sodium cholate-tert-butanol / water (0.1% sodium cholate, 60% tert-butanol) solution to wash out the powder after ball milling, put it in a beaker, ultrasonicate at 250W for 3h, and centrifuge the mixture at 3000rpm for 20min after ultrasonication, and take the upper layer The suspension was filtered, washed and dried to obtain BNNS@SC.

[0064] S2. Preparation of dihydromyricetin-modified hexagonal boron nitride microsheets (h-BN@DMY-200°C): ...

Embodiment 3

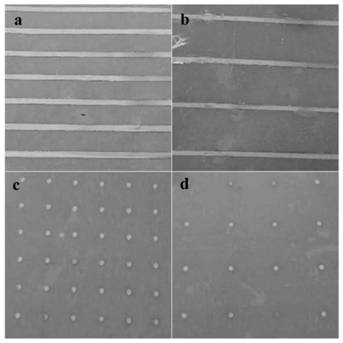

[0076] This embodiment provides a polyimide double-sided flexible heat-conducting copper-clad laminate. The difference between the preparation method of the polyimide double-sided flexible heat-conducting copper-clad laminate and Example 2 is that the pattern of the mask in step S3 is parallel Straight stripes, the stripe hollow width is 1mm, and the stripe interval is 9mm. After the mask is removed, the patterned copper foil Cu-P2 is obtained, such as figure 1 b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com