Insulating wear-resistant anti-corrosion multifunctional coating for track and preparation method thereof

A multi-functional, rail technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. Anti-corrosion, weak anti-corrosion performance and other problems, to achieve the effect of improving the inhibition effect, high economic value, and high insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

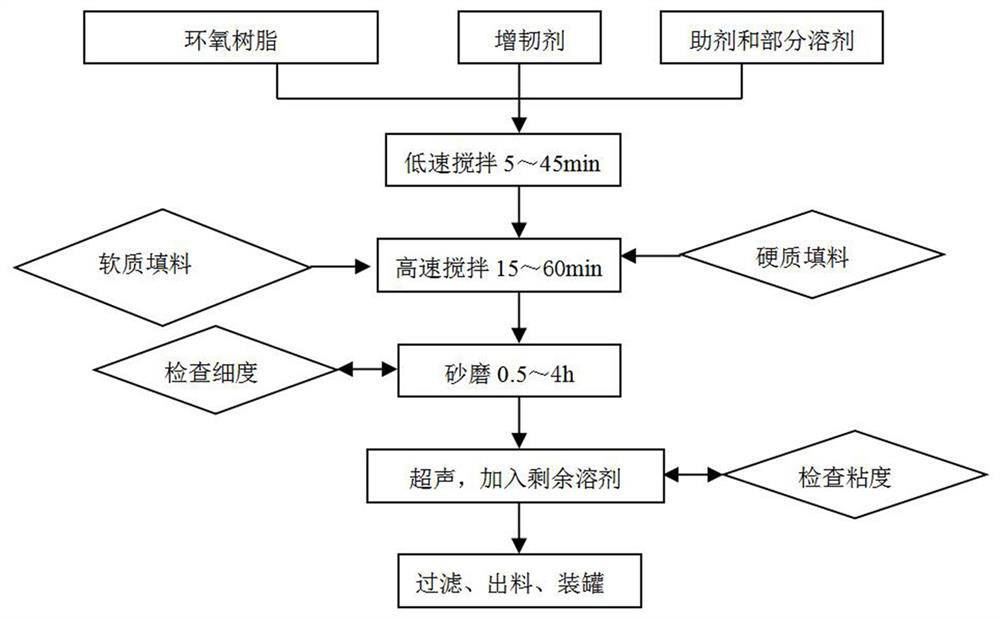

[0050] The invention is prepared by adding hard fillers such as silicon carbide and superfine alumina and soft fillers such as iron red, precipitated barium sulfate and kaolin into the elastic epoxy resin system, and has excellent insulation, wear resistance and anticorrosion properties. The preparation method of the insulating, wear-resistant and anti-corrosion multifunctional coating comprises the following steps:

[0051] Step 1. Material preparation

[0052] Weigh each component according to the number of parts to be measured, and set aside;

[0053] Step 2. Drying of filler

[0054] Place the silicon carbide, ultrafine alumina, iron red, precipitated barium sulfate and kaolin weighed in step 1 in a drying oven at a temperature of 110±5°C for 2 to 12 hours, and cool naturally to room temperature. Each stuffing is bagged and sealed for standby, and marked for standby;

[0055] Step 3, the preparation of ingredient A

[0056] Add the epoxy resin, toughening agent, disper...

Embodiment 1

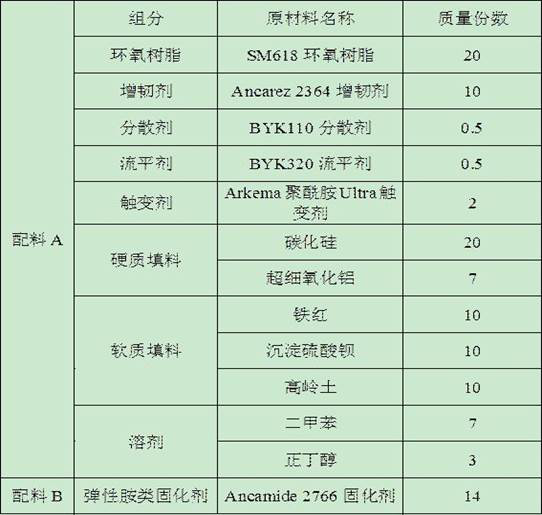

[0063] Table 1 is the coating formula of embodiment 1

[0064] Table 1

[0065]

[0066] The preparation method of present embodiment coating is as follows:

[0067] 1. Preparation of ingredients A

[0068] (1) Drying treatment of filler

[0069] According to the parts by weight in Table 1, weigh silicon carbide, ultra-fine alumina, iron red, precipitated barium sulfate and kaolin, respectively, and place them in a drying oven at a temperature of 110°C for 8 hours, and then naturally cool to room temperature. , bagging, sealing, and labeling each filler separately;

[0070] (2) Preparation of ingredient A

[0071] According to the parts by weight in Table 1, take epoxy resin, toughening agent, dispersant, leveling agent and thixotropic agent, and add 70% of the solvent mass into the disperser, and carry out low-speed dispersion treatment at 700rpm for 30min , after that, add dried silicon carbide, superfine alumina, iron red, precipitated barium sulfate and kaolin, and...

Embodiment 2

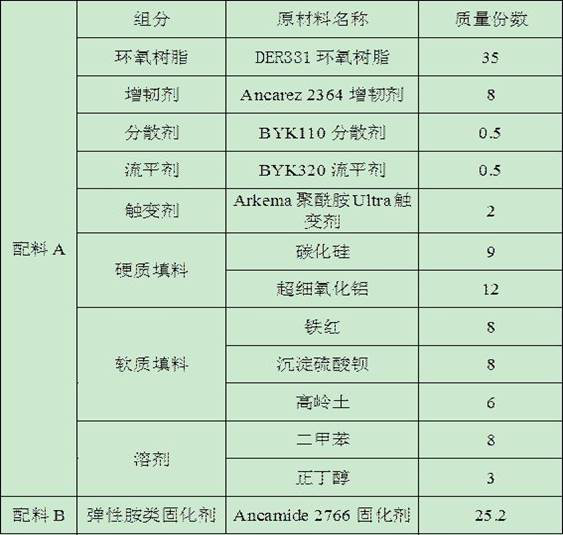

[0077] Table 2 is the coating formula of embodiment 2

[0078] Table 2

[0079]

[0080] The preparation method of present embodiment coating is as follows:

[0081] 1. Preparation of ingredients A

[0082] (1) Drying treatment of filler

[0083] According to the parts by weight in Table 1, weigh silicon carbide, ultrafine alumina, iron red, precipitated barium sulfate, and kaolin, respectively, and place them in a drying oven at a temperature of 115°C for 2 hours, and then naturally cool to room temperature. , bagging, sealing, and labeling each filler separately;

[0084] (2) Preparation of ingredient A

[0085] According to the parts by weight in Table 1, take epoxy resin, toughening agent, dispersant, leveling agent and thixotropic agent, and add 65% of the solvent mass into the disperser, and carry out low-speed dispersion treatment at 900rpm for 5min , after that, add dried silicon carbide, ultra-fine alumina, iron red, precipitated barium sulfate and kaolin, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com