Diffusion bonding method of ternary layered ceramic titanium-silicon-carbon and solid solution thereof and ferritic stainless steel based on Ni foil intermediate layer

A ternary layered, diffusion-connected technology, used in solid electrolyte fuel cells, electrical components, fuel cell components, etc., can solve the problem of long-term stability of the coating that needs to be investigated, and achieve high practical value and anti-oxidation performance. Excellent, low junction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

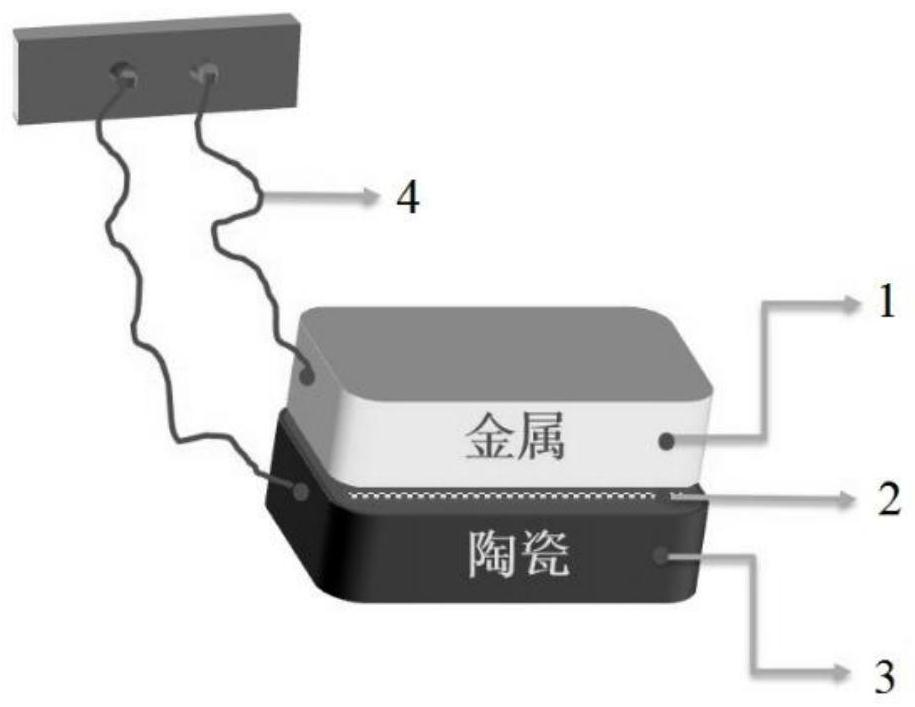

[0028] Will (Ti,Nb) 3 SiC 2Wire cutting for ceramics and Crofer22APU stainless steel, respectively cut into 10*10*2mm 3 The size of the size, then (Ti, Nb) 3 SiC 2 The surface to be connected of ceramics and Crofer22APU stainless steel is polished step by step with 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# metallographic sandpaper, and then polished with diamond abrasive paste with a particle size of 1 μm. 30μm Ni foil, the Ni foil is ultrasonically cleaned and dried for later use. Put the above-mentioned surface-treated materials into the pre-treatment machine, and put them on the horizontal platform according to (Ti, Nb) 3 SiC 2 The order of ceramic / Ni foil / Crofer22APU stainless steel is arranged, and then the welding torch is used on (Ti,Nb) 3 SiC 2 Platinum wires were welded on the 2mm side edges of ceramic and Crofer22APU stainless steel metal blocks. Fix the welded sample in the vacuum chamber of the thermal simulation testing machine, when the vacuum degree r...

Embodiment 2

[0030] Ti 3 SiC 2 Ceramic and Ebrite stainless steel are cut into 10*10*2mm respectively 3 size, and then Ti 3 SiC 2 The surface to be connected of ceramics and Ebrite stainless steel is polished step by step with 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# metallographic sandpaper, and then polished with diamond abrasive paste with a particle size of 1 μm; the thickness is selected to be 50μm Ni foil, the Ni foil was ultrasonically cleaned and dried, and set aside. Put the above-mentioned surface-treated materials into the pre-treatment machine, and place them on the horizontal platform according to Ti 3 SiC 2 Sequential arrangement of ceramic / Ni foil / Ebrite stainless steel, and then welding torch on Ti 3 SiC 2 Platinum wires were welded to the 2 mm side edges of ceramic and Ebrite stainless steel metal blocks. Fix the welded sample in the vacuum chamber of the thermal simulation testing machine, when the vacuum degree reaches 5×10 -3 Start heating at Pa, keep const...

Embodiment 3

[0032] Ti 3 SiC 2 Ceramic and SUS430 stainless steel are cut into 10*10*2mm respectively 3 size, and then Ti 3 SiC 2 The surface to be connected of ceramics and SUS430 stainless steel is polished step by step with 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# metallographic sandpaper, and then polished with diamond abrasive paste with a particle size of 1 μm; the thickness is selected to be 10μm Ni foil, the Ni foil was ultrasonically cleaned and dried, and set aside. Put the above-mentioned surface-treated materials into the pre-treatment machine, and place them on the horizontal platform according to Ti 3 SiC 2 The order of ceramic / Ni foil / SUS430 stainless steel is arranged, and then the Ti 3 SiC 2 Platinum wire is welded on the 2mm side of the ceramic and SUS430 stainless steel metal block. Fix the welded sample in the vacuum chamber of the thermal simulation testing machine, when the vacuum degree reaches 5×10 -3 Start heating at Pa, keep constant pressure for 30mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com