Method for preparing compound type light-weighted reflecting mirror blank and compound type light-weighted reflecting mirror blank

A mirror and lightweight technology, applied in the field of mirrors, can solve the problems of reducing the quality of the mirror body, low yield, insufficient bonding strength of the alloy substrate and glass, etc., and achieve the effects of stable process, high yield, and lower connection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

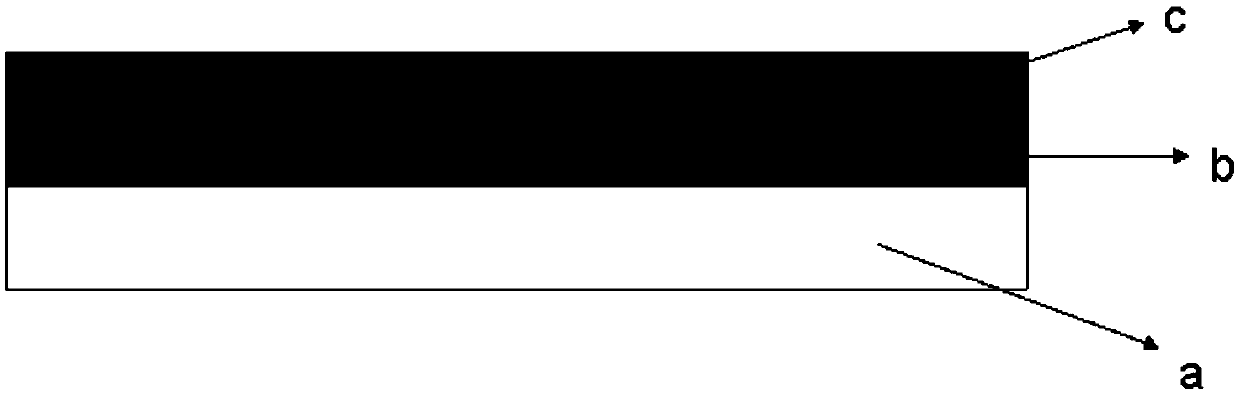

[0035] The preparation method of the composite lightweight reflector blank of the present embodiment comprises the following steps:

[0036] 1) Grinding and polishing: Take a titanium substrate (industrial pure titanium TA1) with a length of 100mm, a width of 70mm, and a height of 12mm, and use 80#, 150#, 400#, 600#, 800#, 1000#, 1400#, 1600 #Water sandpaper grinds the surface step by step to make the surface smooth;

[0037] 2) Alkaline cleaning and degreasing: Soak the titanium base in 85°C mixed lye for 25 minutes to remove the grease on the surface of the titanium base; the mixed lye is 50g of sodium hydroxide, 30g of sodium silicate and 50g of phosphoric acid Made by dissolving sodium in 1000ml water;

[0038] 3) pickling activation: the titanium substrate is placed in the pickling solution for pickling, the pickling time is 60s, the oxide film on the surface of the titanium substrate is removed, the titanium substrate is activated, and an activated substrate is obtained...

Embodiment 2

[0047] The preparation method of the composite lightweight reflector blank of the present embodiment comprises the following steps:

[0048] 1) Grinding and polishing: Take a titanium substrate (titanium alloy TC4) with a length of 100mm, a width of 70mm, and a height of 12mm, and use 80#, 150#, 400#, 600#, 800#, 1000#, 1400#, 1600# for the titanium substrate Water sandpaper grinds the surface step by step to make the surface smooth;

[0049] 2) Alkaline cleaning and degreasing: Soak the titanium base in 90°C mixed lye for 20 minutes to remove the grease on the surface of the titanium base; the mixed lye is 50g of sodium hydroxide, 30g of sodium silicate and 50g of phosphoric acid Made by dissolving sodium in 1000ml water;

[0050] 3) pickling activation: the titanium substrate is placed in the pickling solution for pickling, the pickling time is 90s, the oxide film on the surface of the titanium substrate is removed, the titanium substrate is activated, and an activated subs...

Embodiment 3

[0059] The preparation method of the composite lightweight reflector blank of the present embodiment comprises the following steps:

[0060] 1) Grinding and polishing: Take a titanium substrate (industrial pure titanium TA1) with a length of 100mm, a width of 70mm, and a height of 12mm, and use 80#, 150#, 400#, 600#, 800#, 1000#, 1400#, 1600 #Water sandpaper grinds the surface step by step to make the surface smooth;

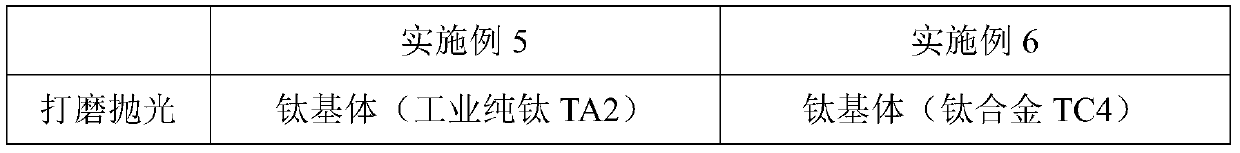

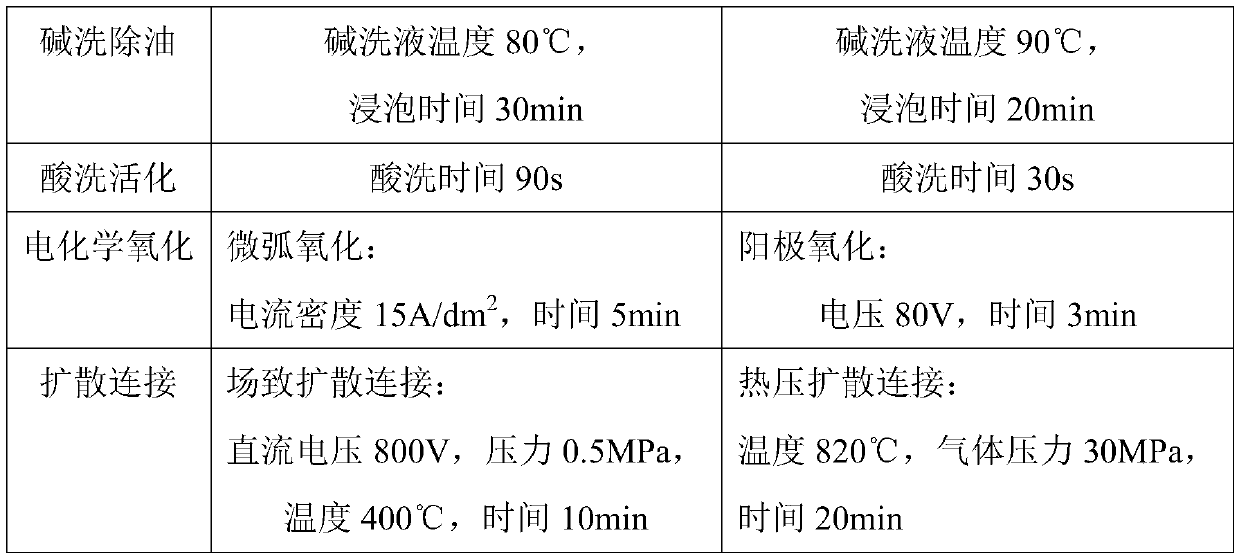

[0061] 2) Alkaline cleaning and degreasing: Soak the titanium substrate in 80°C mixed lye for 30 minutes to remove the grease on the surface of the titanium substrate; the mixed lye is 50g of sodium hydroxide, 30g of sodium silicate and 50g of phosphoric acid Made by dissolving sodium in 1000ml water;

[0062] 3) pickling activation: the titanium substrate is placed in a pickling solution for pickling, the pickling time is 30s, the oxide film on the surface of the titanium substrate is removed, the titanium substrate is activated, and an activated substrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com