Continuous casting three-piece composite oxidation-resistant erosion-resistant ceramic glaze and preparation method thereof

A ceramic glaze and anti-oxidation technology, which is applied in the field of inorganic non-metallic materials for metallurgical continuous casting, can solve the problems of unable to protect the three major pieces of refractory continuous casting, unable to generate liquid phase and glass phase glaze, etc., to achieve good adhesion Effects, easy usage, good antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

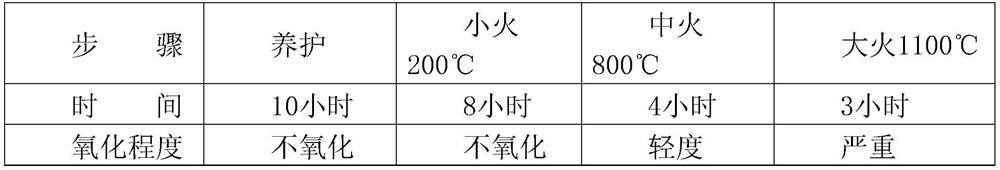

[0027] The present invention will be further described below in combination with specific embodiments.

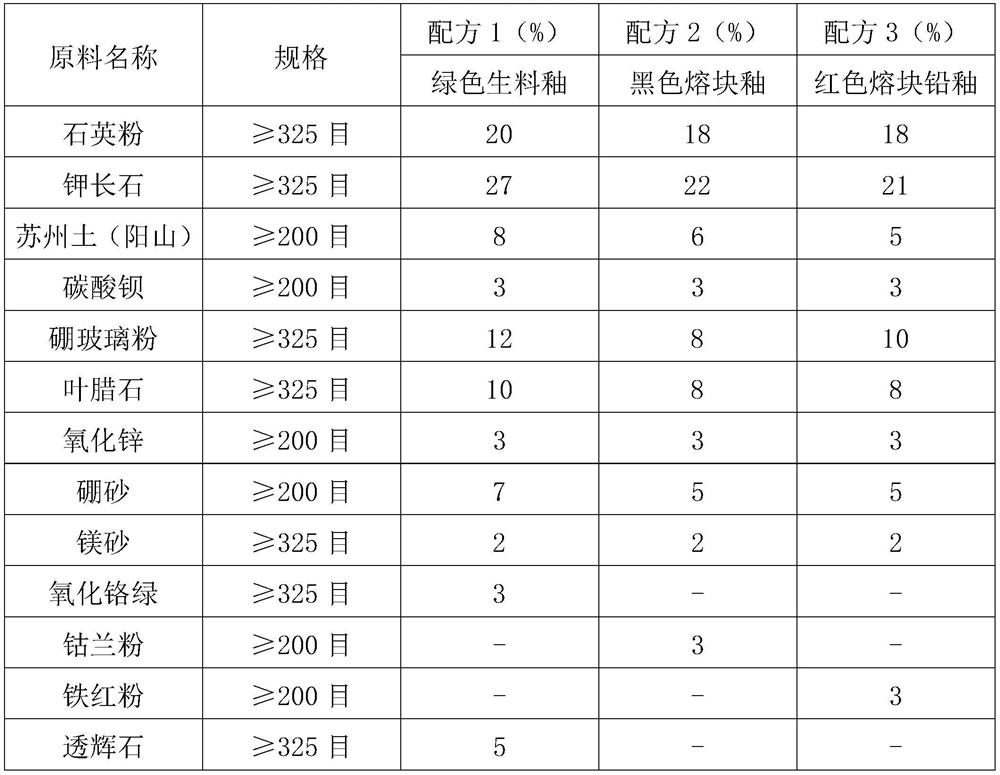

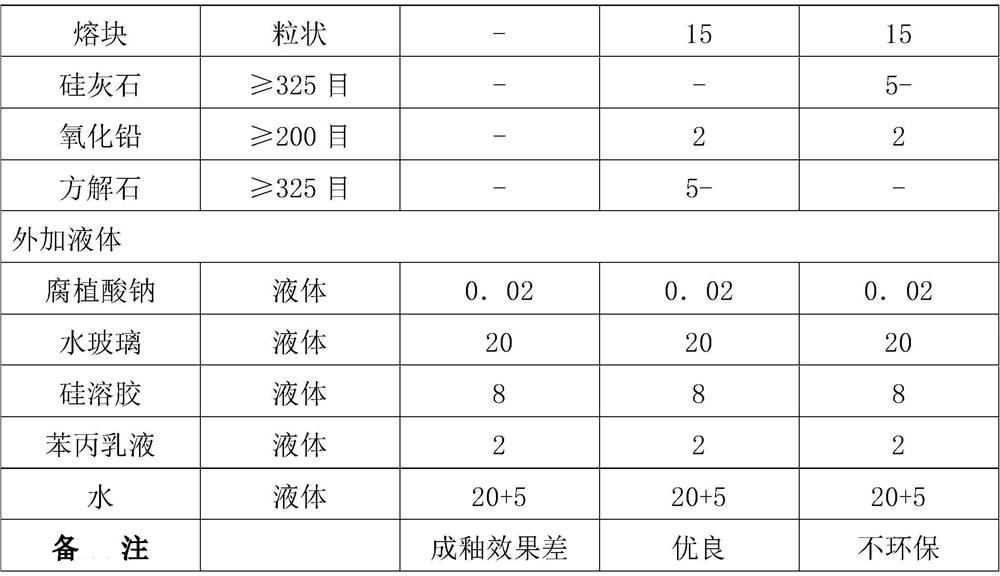

[0028] The composite anti-oxidation and anti-corrosion ceramic glaze for three continuous casting pieces contains the following components by weight percentage: 18%-20% of quartz powder, 21%-27% of potassium feldspar, and 5%-8% of Suzhou soil , barium carbonate 0%~3%, boron glass powder 8%~12%, pyrophyllite 8%~10%, zinc oxide 0%~3%, borax 5%~7%, magnesia 0%~2%, chromium oxide Green 0%~3%, cobalt blue powder 0%~3%, iron red powder 0%~3%, diopside 0%~5%, frit 0%~15%, wollastonite 0%~5%, Lead oxide 0%-2%, calcite 0%-5%, sodium humate 0%-0.2%, binder 0%-20%, silica sol 0%-8%, styrene-acrylic emulsion 0%-2% and water 20% to 25%.

[0029] Among them, the role of calcite in the glaze body:

[0030] 1. Before decomposing, it acts as a barren material in the green body.

[0031] 2. After heating and decomposing, it acts as a flux, and reacts with clay and quartz in the green bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com