Immersion cooling heat dissipation structure, radiator, heat dissipation system and manufacturing method of immersion cooling heat dissipation structure

A technology of immersion cooling and heat dissipation structure, which is applied in the fields of high-efficiency heat transfer structure, heat sink, immersion cooling heat dissipation structure, heat dissipation system and its production, which can solve the problem that the consistency of product performance is difficult to guarantee, and the heat dissipation capacity is difficult to meet the heat dissipation requirements of higher power GPUs. demand and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

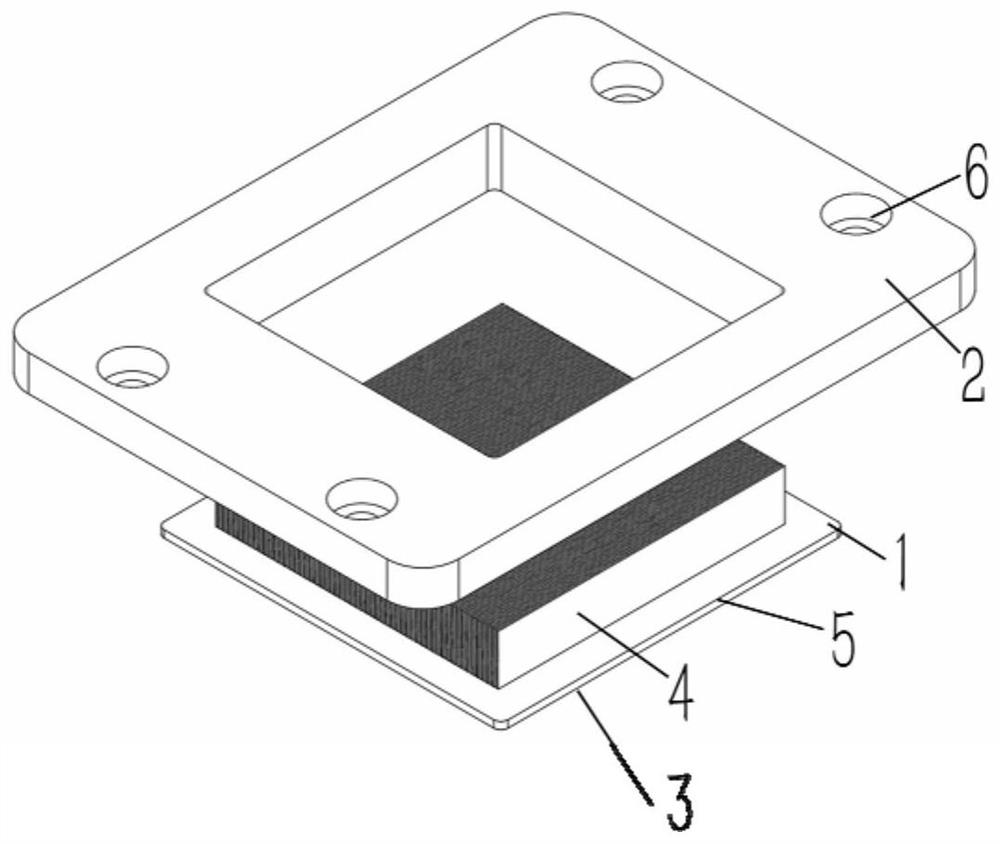

[0099] refer to figure 1 As shown, in a typical embodiment, an immersion cooling radiator includes a boiling heat exchange unit 1 and an upper assembly unit 2 thereof. Wherein, the bottom surface 3 (defined as the second surface) of the boiling heat exchange unit 1 is a smooth surface, and the top surface (defined as the first surface) is processed with a rectangular groove structure 4 . The upper end surface of the assembly unit can be processed with a number of screw holes 6 for fixing, which are used to cooperate with bolts or screws to combine the radiator with the heating element.

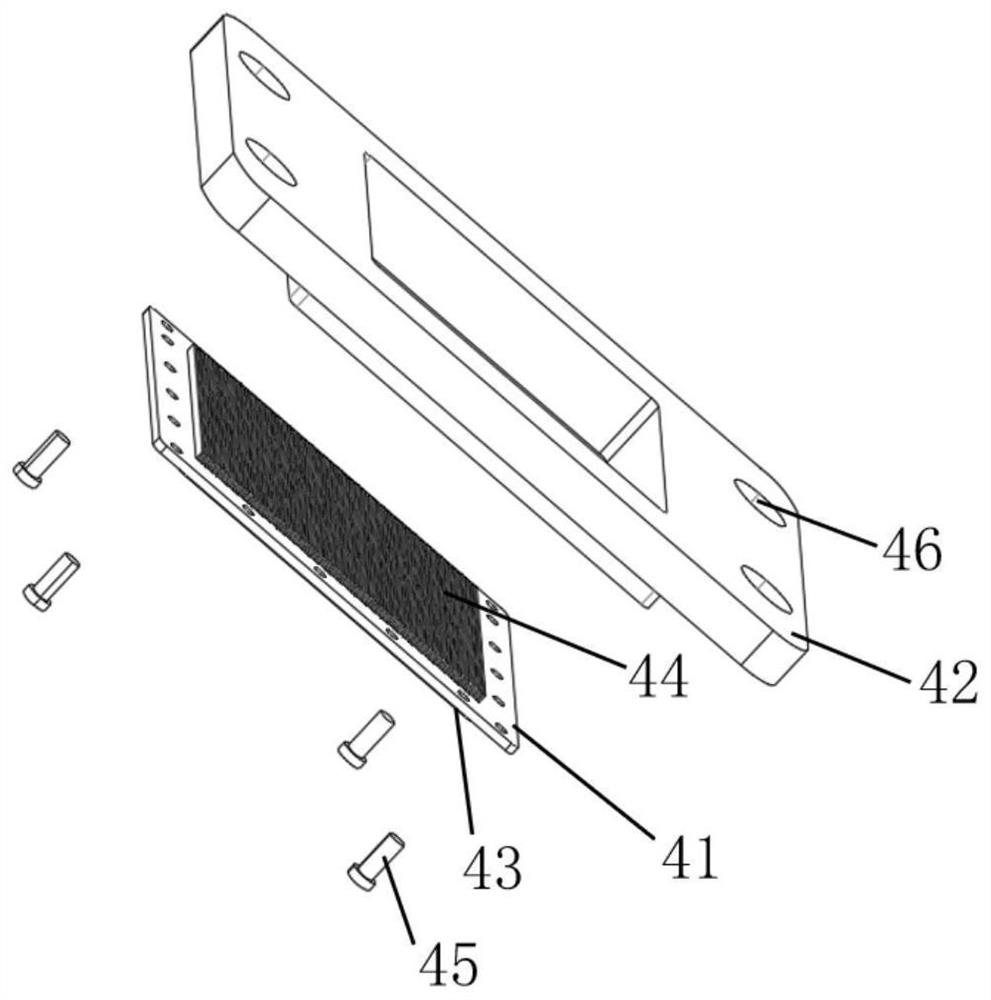

[0100] see again figure 2 As shown, in this embodiment, the boiling heat exchange unit 1 and the assembly unit 2 in the immersion cooling radiator are manufactured separately.

[0101] Among them, the boiling heat exchange unit 1 is a red copper plate, one side of the plate is a smooth surface, and the other side is machined with a rectangular micro-groove structure 4, and the depth and wid...

Embodiment 2

[0108] The submerged cooling radiator provided by this embodiment also has figure 2 The structure shown includes a boiling heat exchange unit 1 and its upper assembly unit 2; the boiling heat exchange unit 1 is a copper flat plate, one side of which is a smooth surface, and the other side adopts a tooth-shoveling machine to process a rectangular micro-groove structure 4, each The depth and width of the rectangular microgrooves are the same; the assembly unit is made of copper substrate, and the bottom edge is connected with the edge 5 of the side containing the microgrooves of the boiling heat exchange unit through friction welding. Fixing screw holes 6 are processed on the upper surface of the assembly unit, and the heating element is connected with the smooth surface of the boiling heat exchange unit through a film-shaped heat-conducting material (not shown in the figure).

[0109] In this embodiment, the aforementioned microgrooves have a depth of 8 mm, a width and a pitch...

Embodiment 3

[0113] The submerged cooling radiator provided by this embodiment also has figure 2 The structure shown includes a boiling heat exchange unit 1 and an assembly unit 2; the boiling heat exchange unit 1 is a copper plate, one side of which is a smooth surface, and the other side adopts a spade machine to process a rectangular groove structure 4, the depth of the rectangular groove and The widths are all the same; the assembly unit is made of red copper base material, and the bottom edge is connected to the edge 5 of the side containing the microgroove of the boiling heat exchange unit by soldering, and the welding temperature is 230°C. The upper surface of the assembly unit is processed with screw holes 6 for fixing, and the heating element and the smooth surface of the boiling heat exchange unit are connected through a film-shaped heat-conducting material (not shown in the figure).

[0114] In this embodiment, the aforementioned microgrooves have a depth of 8 mm, a width and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com