Perovskite nano-material, composite luminescent material containing perovskite nano-material, and preparation method and application thereof

A technology of nanomaterials and luminescent materials, applied in the field of materials, can solve the problems that β-CsPbI cannot exist stably at room temperature, cannot meet the production conditions, and loses the size limitation effect, and achieves broad market application prospects, excellent luminescent performance, and stable fluorescence Sexual Enhancement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

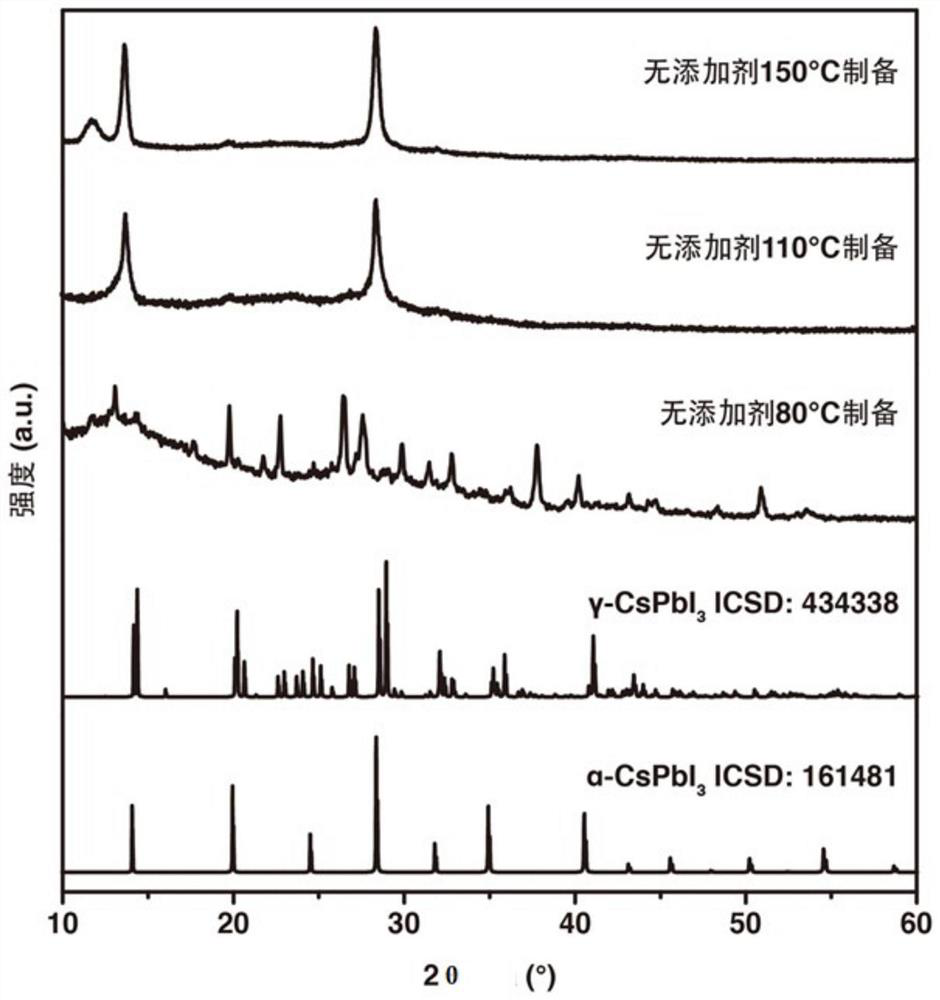

[0156] The rest of the steps are the same as in Comparative Example 1, the difference is that in solution A, the polymer is polyacrylonitrile (PAN), the organic solvent is dimethyl sulfoxide (DMSO), and the mass ratio of polymer to organic solvent is 1:6 , adding the additive ZnI 2 , to control the mass ratio for the polymer:ZnI 2 =1:0.5, the mechanical stirring is not less than 6h to obtain a clear and transparent solution. In B solution, the organic solvent is dimethyl sulfoxide (DMSO), control PbI 2 : The molar ratio of CsI is 1:0.75, and the organic solvent is controlled: (PbI 2 +CsI) has a mass ratio of 1:0.001. In the precursor solution, the mass ratio of solution A: solution B is controlled to be 1:1. The precursor solution was transferred to a transparent glass sheet by dipping and pulling method, and the thickness of the precursor solution on the transparent glass sheet was controlled to be 0.2 mm. The air pressure in the vacuum drying oven was 0.01 MPa, the tempe...

Embodiment 2

[0158] All the other steps are with embodiment 1, difference is, control organic solvent: (PbI 2 +CsI) with a mass ratio of 1:0.1. Stir mechanically to mix the solution evenly, remove the solvent in a vacuum oven and place it on a heating plate at 150°C for 10 minutes to obtain γ-CsPbI 3 Quantum dot / PAN composite film. Figure 5 It is the emission spectrum diagram of the sample, and the luminescence peak is located at 606nm. This sample XRD test result and Figure 4 Similarly, the XRD pattern shows that the sample is in the gamma phase.

Embodiment 3

[0160] All the other steps are with comparative example 1, and difference is, in first solution, polymer is polyvinylidene chloride (PVDF), and organic solvent is trimethyl phosphate (TMP), and control polymer: the mass ratio of organic solvent is 1:15. In the second solution, the organic solvent is trimethyl phosphate (TMP), and the organic solvent and (PbI 2 +CsI) with a mass ratio of 1:0.2, PbI 2 The molar ratio to CsI is 1:0.1. The mass ratio of solution A and solution B is 1:0.02. Transfer the precursor solution to the glass petri dish by the solution sinking method, control the thickness of the precursor solution in the glass petri dish to 5mm, the air pressure in the vacuum drying oven is 0.05MPa, the temperature is 110°C, and dry for 10h to obtain γ-CsPbI 3 Quantum dot / PVDF composite film. Figure 6 It is the emission spectrum diagram of the sample, and the luminescence peak is located at 655nm. This sample XRD test result and Figure 4 Similarly, the XRD pattern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com