Macroporous ion exchange resin with function of highly selectively adsorbing rhenium metal ions and preparation method of macroporous ion exchange resin

An ion exchange resin and selective adsorption technology, which is applied in the direction of cation exchange materials, chemical instruments and methods, and other chemical processes, can solve the problems of complex process, low rhenium yield, and easy emulsification, so as to improve ion exchange rate, Effect of increasing the amount of amino grafts and enhancing the adsorption capacity of rhenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

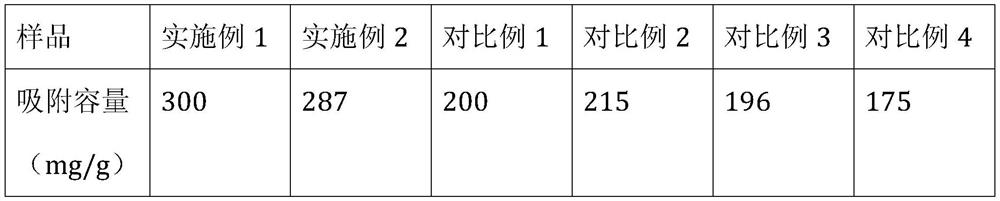

Examples

Embodiment 1

[0023] A preparation method of a macroporous ion exchange resin with highly selective adsorption of rhenium metal ions, comprising the following steps:

[0024] S1. Polymerization: Monomer methyl acrylate and cross-linking agent divinylbenzene are used to prepare white balls by suspension polymerization, in which ternary porogen diethylbenzene-isobutanol-toluene is added;

[0025] S2. Amino functionalization and cross-linking: After the white ball is fully swollen, add triethylenetetramine to reflux in a water bath at 70°C, add glutaraldehyde dropwise, continue to reflux in a water bath, and react for 3 hours;

[0026] S4. Methylation: mix the aminated sphere with formic acid, formaldehyde, and water, the mass ratio of the aminated sphere to formic acid, formaldehyde, and water is 18:200:3:40, and react at 50°C for 60 minutes to obtain the intermediate product resin A;

[0027] S4. Inorganic modification: the intermediate product resin A is soaked in NaOH solution, washed with...

Embodiment 2

[0029] A preparation method of a macroporous ion exchange resin with highly selective adsorption of rhenium metal ions, comprising the following steps:

[0030] S1. Polymerization: Preparation of seed white balls by precipitation polymerization: add divinylbenzene, methyl acrylate, initiator azobisisobutyronitrile, ternary porogen diethylbenzene-isobutanol-toluene and The solvent is acetonitrile, ultrasonically dispersed, nitrogen deoxygenated, heated to 70°C, reacted for 4 hours, suction filtered, washed, and dried;

[0031] S2. Amino functionalization and cross-linking: After the white ball is fully swollen, add triethylenetetramine to reflux in a water bath at 70°C, add glutaraldehyde dropwise, continue to reflux in a water bath, and react for 3 hours;

[0032] S4. Methylation: mix the aminated sphere with formic acid, formaldehyde, and water, the mass ratio of the aminated sphere to formic acid, formaldehyde, and water is 18:200:3:40, and react at 50°C for 60 minutes to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com