Macroporous adsorption resin for blood perfusion and preparation method thereof

A technology of hemoperfusion and pore adsorption, which is applied in blood circulation treatment, chemical instruments and methods, and other chemical processes, can solve the problems of lowering polymer reaction temperature, lowering reaction rate, and large adsorption capacity, so as to improve mechanical strength, Effect of reducing melt viscosity and increasing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

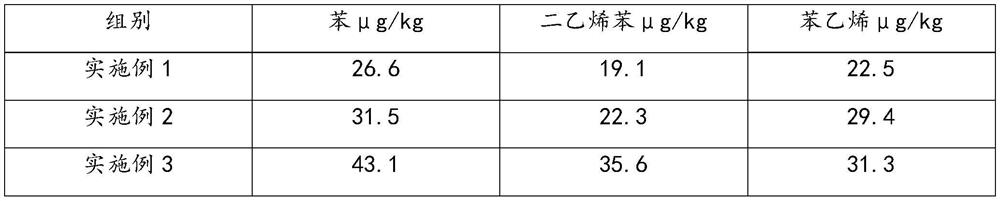

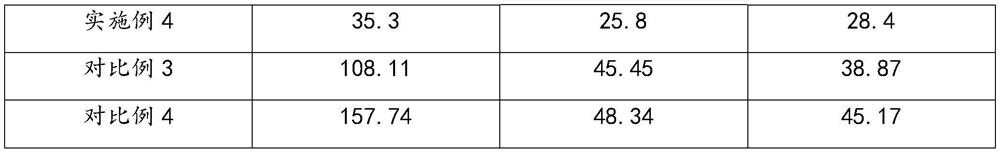

Examples

Embodiment 1

[0029] Embodiment 1 A kind of macroporous adsorbent resin for hemoperfusion

[0030] The preparation method of described macroporous adsorption resin comprises the following steps:

[0031] S1. Add 2kg of styrene, 6.5kg of divinylbenzene, 1kg of methyl acrylate, 0.01kg of gelatin derivatives, 14.25kg of toluene, 0.285kg of BPO, and 0.001kg of light magnesium oxide into the reaction kettle to form an oil phase, and stir it mechanically Add 3 times the mass fraction of the oil phase deionized water and raise the temperature to 70°C, keep the stirring speed in the reactor at 250 rpm, so that the oil phase forms uniform beads and disperses in the water phase, and keep the temperature for 2 hours Afterwards, heat up to 90°C and continue the heat preservation reaction for 4 hours to obtain polystyrene-divinylbenzene microspheres, wash them with water, dry them, and then use edible alcohol to extract toluene until clean, dry, and wet sieve to obtain a particle size of 0.3-1.5mm whit...

Embodiment 2

[0035] Embodiment 2 A kind of macroporous adsorbent resin for hemoperfusion

[0036] The preparation method of described macroporous adsorption resin comprises the following steps:

[0037] S1. Add 2.5kg of styrene, 7kg of divinylbenzene, 8kg of vinyl acetate, 0.06kg of gelatin derivatives, 10.kg of cyclohexane, 0.206kg of ABIN and 0.012kg of light magnesium oxide into the reactor to form an oil phase, Under mechanical stirring, add 1.2 times the deionized water of the mass fraction of the oil phase and heat up to 75°C, keep the stirring speed in the reactor at 300 rpm, so that the oil phase forms uniform beads and disperses in the water phase. After heat preservation reaction for 1.5 hours, heat up to 90°C and continue heat preservation reaction for 2 hours to obtain polystyrene-divinylbenzene microspheres, wash them with water, dry them, then use edible alcohol to extract toluene until clean, dry, and wet sieve Obtain white balls with a particle size of 0.3-1.5mm;

[0038] S...

Embodiment 3

[0041] Embodiment 3 A kind of macroporous adsorbent resin for hemoperfusion

[0042] The preparation method of described macroporous adsorption resin comprises the following steps:

[0043] S1. Add 2.2kg of styrene, 7.5kg of divinylbenzene, 0.001kg of TAIC triallyl isocyanurate, 0.15kg of gelatin derivatives, 0.605kg of dichloroethane, 0.087kg of BPO and light Mix 0.001kg of magnesium oxide to form an oil phase. Under mechanical stirring, add deionized water of 5 times the mass fraction of the oil phase and heat up to 70°C. Keep the stirring speed in the reactor at 250 rpm to make the oil phase uniform. The beads were dispersed in the water phase, and after 2 hours of heat preservation reaction, the temperature was raised to 90°C for 4 hours of heat preservation reaction to obtain polystyrene-divinylbenzene microspheres, which were washed with water, dried, and then extracted toluene with edible alcohol to Clean, dry, and wet sieve to obtain white balls with a particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com