Short carbon fiber-reinforced boron carbide composite material and preparation method thereof

A technology of short carbon fibers and composite materials, which is applied in shielding, nuclear engineering, reactors, etc., can solve the problems of enhanced boron carbide neutron-absorbing performance, complicated preparation process, and high equipment requirements, so as to improve neutron-absorbing efficiency and prepare The process is simple and the effect of product performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

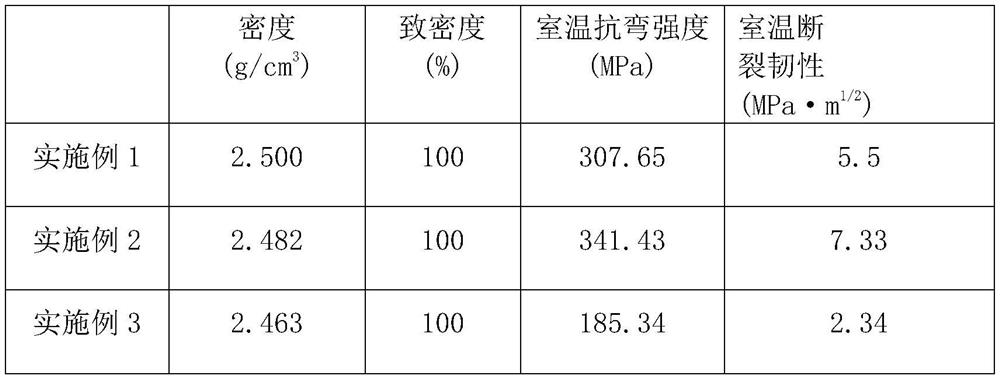

Embodiment 1

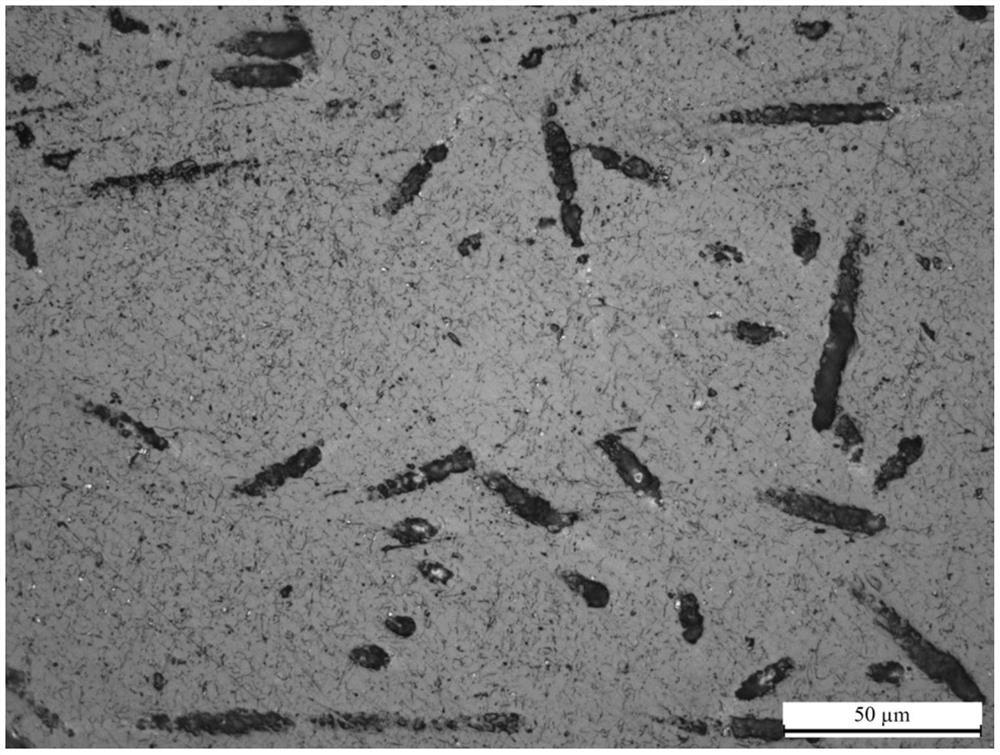

[0047] Weigh 97.5vt.% boron carbide powder with a particle size of about 3.5μm and 2.5vt.% short carbon fiber, and mix the two uniformly and dry under a magnetic stirrer to obtain a mixed powder of B4C and short carbon fiber. The purity of the boron carbide powder is greater than 99%, containing trace Fe or graphite carbon; short carbon fiber is T300 type with a diameter of 7μm.

[0048] Pour the mixed powder into a Φ40mm graphite mold. The mold and the powder are separated by graphite paper, and sent to the spark plasma sintering equipment (FCT D25 / 3) for sintering. The vacuum is 1Pa, the pre-pressure is 8MPa, and the current parameter is on-off. Under the condition of 8ms-2ms, continue to pressurize to 45MPa, and raise the temperature to 2000°C at a heating rate of 100°C / min. After keeping the temperature for 20 minutes, it is cooled to 500°C at a cooling rate of 100°C / min and the furnace is cooled to room temperature;

[0049] The mold is taken out from the spark plasma sinteri...

Embodiment 2

[0052] Weigh 95vt.% of boron carbide powder with a particle size of about 3.5μm and 5vt.% of short carbon fiber, mix them evenly and dry under a magnetic stirrer to obtain a mixed powder of B4C and short carbon fiber. The purity of the boron carbide powder is greater than 99% , Containing trace Fe or graphite carbon; Short carbon fiber is T300 type with a diameter of 7μm.

[0053] Pour the mixed powder into a Φ40mm graphite mold. The mold and the powder are separated by graphite paper, and sent to the spark plasma sintering equipment (FCT D25 / 3) for sintering. The vacuum is 1Pa, the pre-pressure is 8MPa, and the current parameter is on-off. Under the condition of 8ms-2ms, continue to pressurize to 45MPa, and raise the temperature to 2000°C at a heating rate of 100°C / min. After keeping the temperature for 20 minutes, it is cooled to 500°C at a cooling rate of 100°C / min and the furnace is cooled to room temperature;

[0054] The mold is taken out from the spark plasma sintering furn...

Embodiment 3

[0057] Weigh 92.5vt.% of boron carbide powder with a particle size of about 3.5μm and 7.5vt.% of short carbon fiber, mix the two evenly and dry under a magnetic stirrer to obtain a mixed powder of B4C and short carbon fiber. The purity of the boron carbide powder is greater than 99%, containing trace Fe or graphite carbon; short carbon fiber is T300 type with a diameter of 7μm.

[0058] Pour the mixed powder into a Φ40mm graphite mold. The mold and the powder are separated by graphite paper, and sent to the spark plasma sintering equipment (FCT D25 / 3) for sintering. The vacuum is 1Pa, the pre-pressure is 8MPa, and the current parameter is on-off. Under the condition of 8ms-2ms, continue to pressurize to 45MPa, and raise the temperature to 2000°C at a heating rate of 100°C / min. After keeping the temperature for 20 minutes, it is cooled to 500°C at a cooling rate of 100°C / min and the furnace is cooled to room temperature;

[0059] The mold is taken out from the spark plasma sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com