Gradient nanostructured metal material and preparation method thereof

A technology of metal materials and nanostructures, applied in the field of precision processing, can solve the problems that the toughness and strength of metal materials cannot be improved at the same time, achieve the effect of simple and easy to operate preparation method, realize use requirements, high material strength and material toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

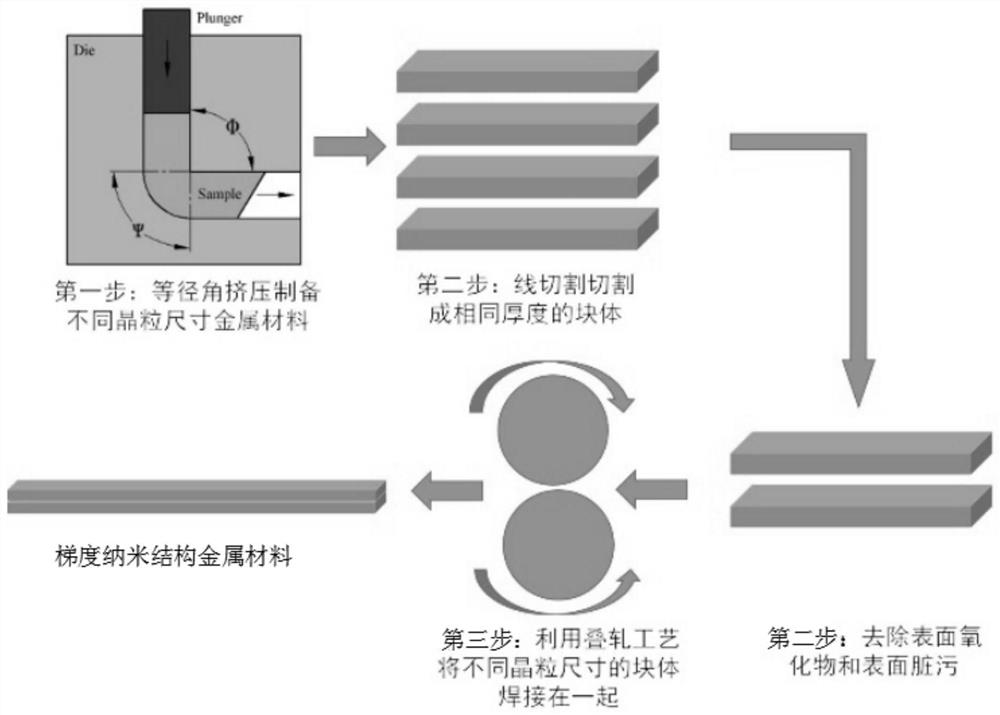

[0034] A first aspect of the embodiments of the present application provides a method for preparing a gradient nanostructured metal material, such as figure 1 shown, including the following steps:

[0035] S01. Provide n pieces of original metal materials, and use the equal-diameter angular extrusion process to perform extrusion processing on the original metal materials in different passes to obtain n pieces of metal materials with different grain sizes, wherein n is not less than 3;

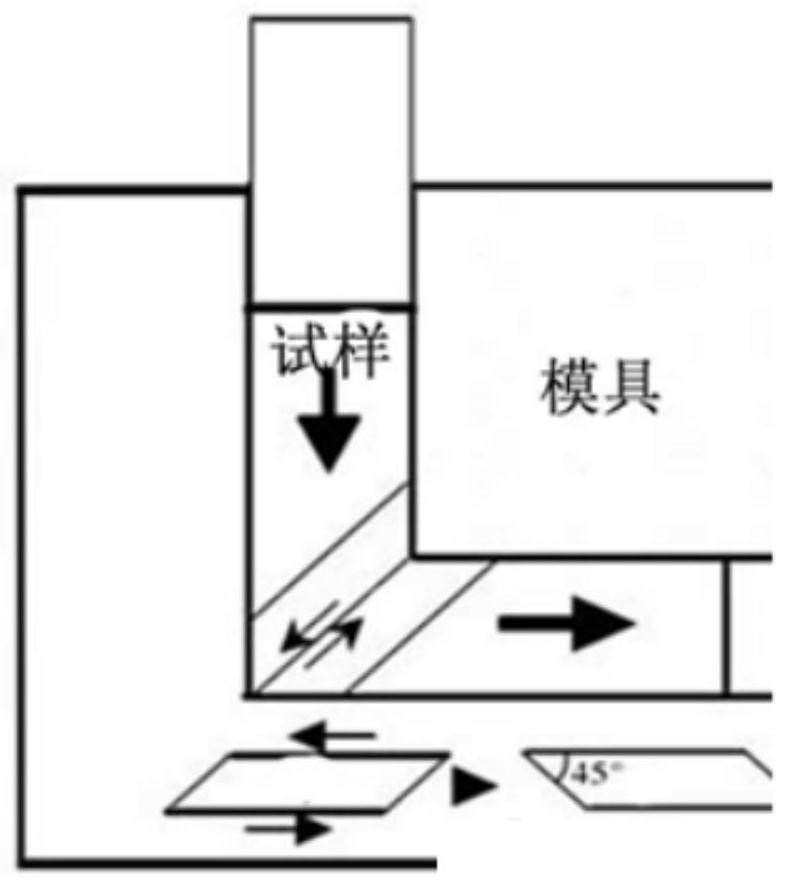

[0036]S02. The n pieces of the metal material are respectively cut by a wire cutting process, and the impurity removal treatment is carried out to obtain n pieces of metal material sheets with different grain sizes;

[0037] S03. Provide the original metal material sheet and the coarse-grained metal material sheet, and arrange the n pieces of the metal material sheet in order according to the size of the crystal grains, and use the cumulative rolling welding process to carry out the rolling pr...

Embodiment 1

[0071] Pure copper gradient nanostructured metal material and preparation method thereof

[0072] Preparation method of pure copper gradient nanostructured metal material

[0073] The preparation method of pure copper gradient nanostructure metal material comprises the following steps:

[0074] Provide pure copper original metal material, wherein the original material is selected from pure copper bars with a diameter of 15mm and an average grain size of about 7μm;

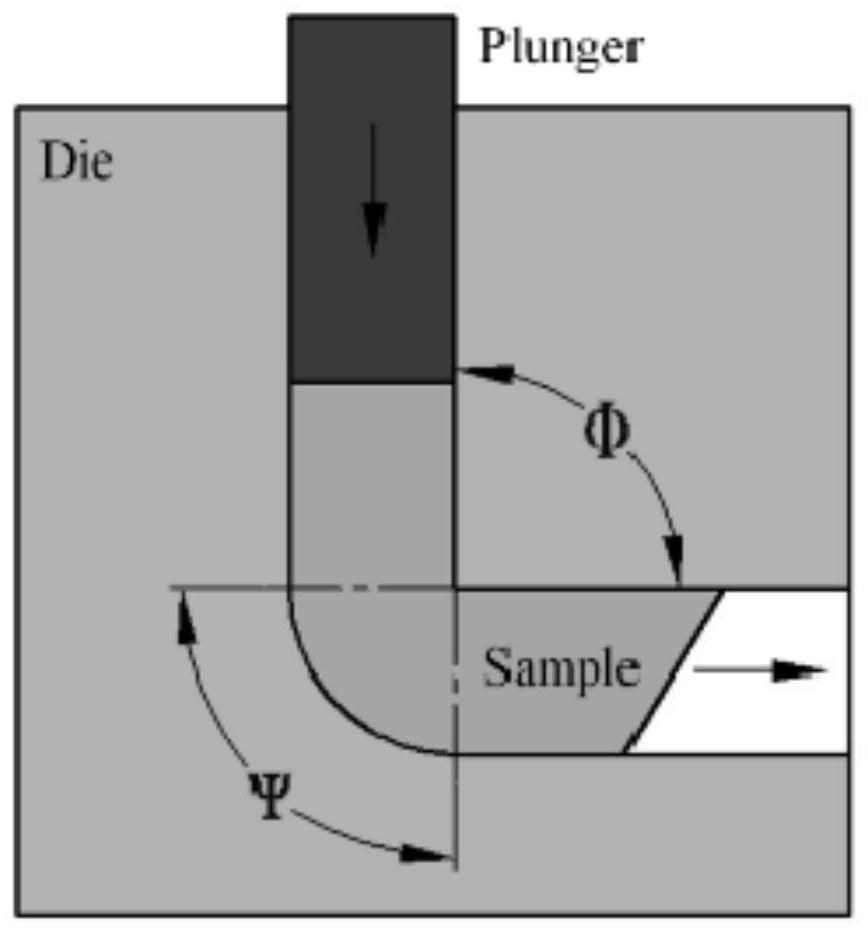

[0075] The three pure copper bars were extruded for 4 passes, 6 passes and 8 passes respectively by the equal-diameter angular extrusion process to obtain 3 metal materials with different grain sizes; The treatment temperature is room temperature 25°C, the inner mold corner Φ where the channels intersect is 90°; the mold center angle Ψ where the channels intersect is 90° for equal-diameter angular extrusion treatment. Further, the average grain size of the pure copper material subjected to 4 passes of extrusion...

Embodiment 2

[0083] 6061 aluminum alloy gradient nanostructured metal material and preparation method thereof

[0084] Preparation method of 6061 aluminum alloy gradient nanostructured metal material

[0085] The preparation method of 6061 aluminum alloy gradient nanostructure metal material comprises the following steps:

[0086] Provide 6061 aluminum alloy raw metal materials, wherein the raw materials are selected from pure copper bars with a diameter of 15mm and an average grain size of about 7μm;

[0087] The three 6061 aluminum alloy bars were extruded for 4 passes, 6 passes and 8 passes respectively by the equal-diameter angular extrusion process to obtain 3 pieces of metal materials with different grain sizes; The temperature of the pressure treatment is room temperature 25°C, the inner die corner Φ where the channels intersect is 90°; the central angle Ψ of the die where the channels intersect is 90° for equal-diameter angular extrusion treatment. Further, the average grain si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com