Preparation method of clay anti-sensitivity solid polycarboxylate superplasticizer

A clay anti-sensitivity and polycarboxylate technology, which is applied in the field of preparation of clay anti-sensitivity solid polycarboxylate superplasticizers, can solve the problems of inconvenient storage and transportation, high production energy consumption, and destruction of polycarboxylate superplasticizer molecules structural issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

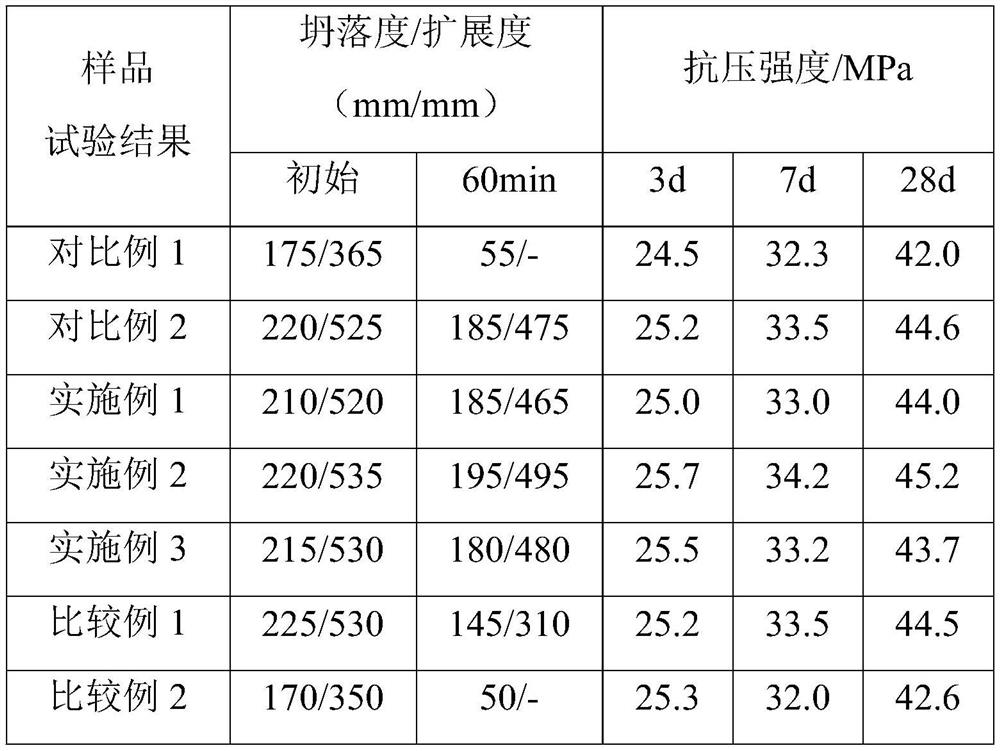

Examples

Embodiment 1

[0029] A preparation method of clay antisensitivity solid polycarboxylate water reducer, comprising the following steps:

[0030] Step 1: Add 240g prenyl polyoxyethylene ether (molecular weight 2400) and 1.2g polyethylene glycol 800 (PEG-800) into the reactor, heat up to 70°C, fully melt and stir for later use;

[0031] Step 2: Add 0.25 g of concentrated sulfuric acid, 5.3 g of 60% dimethyl diallyl ammonium chloride, and 0.5 g of azobisisobutylcyanide to the liquid obtained in step 1, and stir for 10 minutes to dissolve and mix;

[0032] Step 3: The reaction temperature is controlled at 70-75°C, and the mixture of 34.2g of acrylic acid, 6.5g of hydroxypropyl acrylate, 1.25g of azobisisobutylcyanide and 2.0g of mercaptoacetic acid is added dropwise at a constant speed to the liquid obtained in step 2, The dripping time is 3h respectively; after the dripping is finished, continue the insulation reaction for 1.5h;

[0033] Step 4: Add 5.0 g of triethanolamine to the liquid obtai...

Embodiment 2

[0035] A preparation method of clay antisensitivity solid polycarboxylate water reducer, comprising the following steps:

[0036] Step 1: Add 240g isopentenyl polyoxyethylene ether (molecular weight 2400), 2.0g fatty alcohol polyoxyethylene ether (Pingpingjia O-25) into the reaction kettle, heat up to 65°C, fully melt and stir for later use;

[0037] Step 2: Add 0.25 g of concentrated sulfuric acid, 5.2 g of 80% methacryloyloxyethyltrimethylammonium chloride, and 0.5 g of azobisisoheptylcyanide to the liquid obtained in step 1, and stir for 10 minutes to dissolve and mix;

[0038] Step 3: The reaction temperature is controlled at 60-65°C, and the mixture of 36g of acrylic acid, 9.3g of hydroxyethyl acrylate, 1.0g of azobisisoheptyl cyanide and 1.5g of mercaptopropionic acid is added dropwise at a constant speed to the liquid obtained in step 2, The dripping time is 3.5h respectively, and after the dripping is finished, the insulation reaction is continued for 1.5h;

[0039] S...

Embodiment 3

[0041] A preparation method of clay antisensitivity solid polycarboxylate water reducer, comprising the following steps:

[0042] Step 1: Add 300g isopentenyl polyoxyethylene ether (molecular weight 3000) and 2.5g alkylphenol polyoxyethylene ether (OP-10) into the reaction kettle, heat up to 75°C, fully melt and stir for later use;

[0043] Step 2: Add 0.3 g of concentrated sulfuric acid, 8.25 g of 75% (3-acrylamidopropyl) trimethylammonium chloride, and 0.6 g of dimethyl azobisisobutyrate to the liquid obtained in step 1, and stir for 5 minutes to make it well mixed;

[0044] Step 3: Control the reaction temperature at 75-80°C, and add 39.6g of acrylic acid, 9.1g of hydroxypropyl acrylate, 1.2g of dimethyl azobisisobutyrate and 2.5g of mercapto to the liquid obtained in step 2. For the mixed solution of propionic acid, the dropwise addition time is 3h; after the dropwise addition, continue the heat preservation reaction for 1h;

[0045] Step 4: Add 8.5 g of triethanolamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com