Thin-film lithium niobate-based integrated chip and preparation method thereof

An integrated chip and lithium niobate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor passband shape of the filter, difficulty in application, low stability and reliability, etc., to achieve accurate splitting ratio, The effect of large working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Its preparation method specifically comprises the following steps:

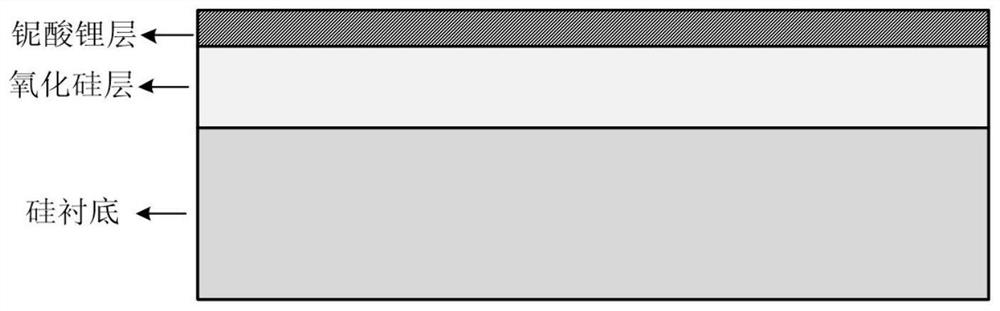

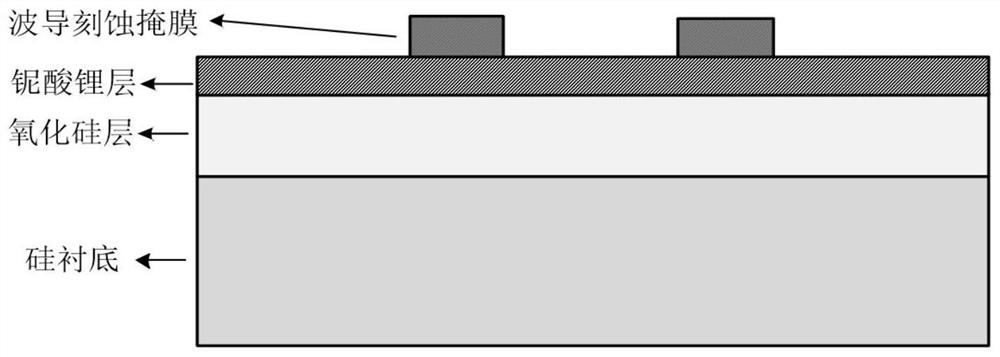

[0051] 1) On the silicon-based thin film lithium niobate substrate material, the waveguide pattern mask is prepared by electron beam exposure technology. The electron beam glue adopts HSQ negative glue with a thickness of 500-800 nanometers, such as figure 1 , figure 2 shown;

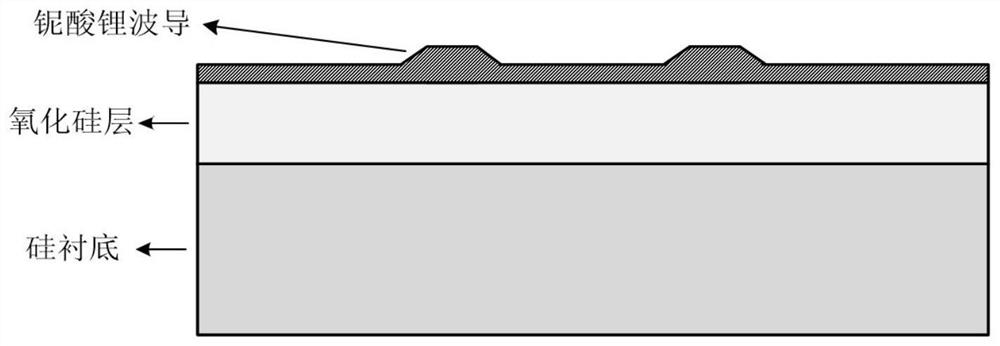

[0052] 2) The lithium niobate waveguide is prepared by inductively coupled plasma etching based on sulfur hexafluoride gas, and the etching depth is 250-350 nm, such as image 3 shown;

[0053] 3) Using plasma-enhanced chemical vapor deposition to grow a silicon oxide upper cladding layer with a thickness of 1-3 microns, such as Figure 4 shown;

[0054] 4) The photoresist pattern of the dielectric hole is prepared by planar photolithography and development technology. The photoresist can be selected from AZ 7908, AZMIR 701 or AZ 4562, the thickness is greater than the thickness of the silicon oxide cladding, and the photor...

Embodiment 1

[0058] The filtering and delay implementation methods are as follows:

[0059] 1) Initial state debugging: first adjust U1 to adjust the first ring to an over-coupling state, then adjust U3 and U4 to adjust the resonance wavelengths of the two resonant cavities to be the same, that is, adjust to a resonance peak, and adjust U2 to adjust the second The ring is tuned to an over-coupling state.

[0060] 2) Bandwidth-tunable filtering: In the initial state, change U2 (in the over-coupling state), and fine-tune U1 accordingly to achieve a filter response with a constant central wavelength and adjustable bandwidth, such as Figure 9 shown.

[0061] 3) Adjustable central wavelength filtering: In the initial state, change U1 to achieve a filter response with constant bandwidth and adjustable central wavelength, such as Figure 10 shown.

[0062] 4) Simultaneously adjustable bandwidth and center wavelength filtering: In the initial state, change U2 (in the over-coupling state) and U...

Embodiment 2

[0068] A method for preparing a thin-film lithium niobate-based integrated chip, specifically comprising the following steps:

[0069] 1) On the silicon-based thin-film lithium niobate substrate material, the mask of the waveguide pattern is prepared by electron beam exposure technology. The electron beam glue uses HSQ negative glue with a thickness of 600 nanometers, such as figure 1 , figure 2 shown;

[0070] 2) The lithium niobate waveguide was prepared by inductively coupled plasma etching based on sulfur hexafluoride gas, with an etching depth of 300 nm, such as image 3 shown;

[0071] 3) Using plasma-enhanced chemical vapor deposition to grow a silicon oxide upper cladding layer with a thickness of 2 microns, such as Figure 4 shown;

[0072] 4) The photoresist pattern of the dielectric hole is prepared by planar photolithography and development technology. The photoresist is AZ MIR 701 with a thickness of 2.5 microns, and the electrodes are etched by inductively c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com