Gas-barrier moisture-permeable film containing sulfonated polyaromatic ether polymer as well as preparation method and application thereof

A technology of polymers and aromatic ethers, applied in the direction of chemical instruments and methods, applications, special packaging objects, etc., can solve the problems of complicated process, moisture permeability that cannot be changed with humidity, and high price, and achieve a tight molecular structure and good Oxygen barrier properties, effects of excellent gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

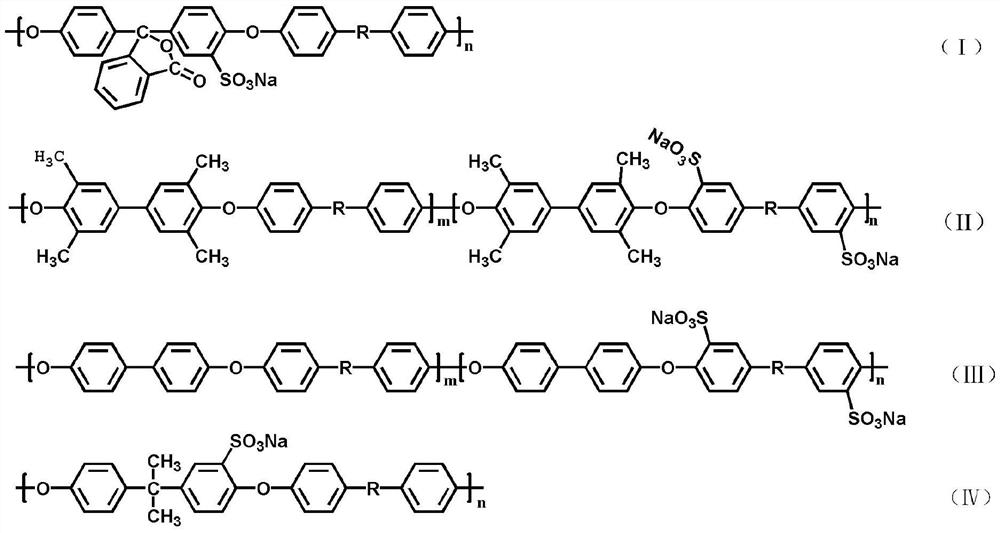

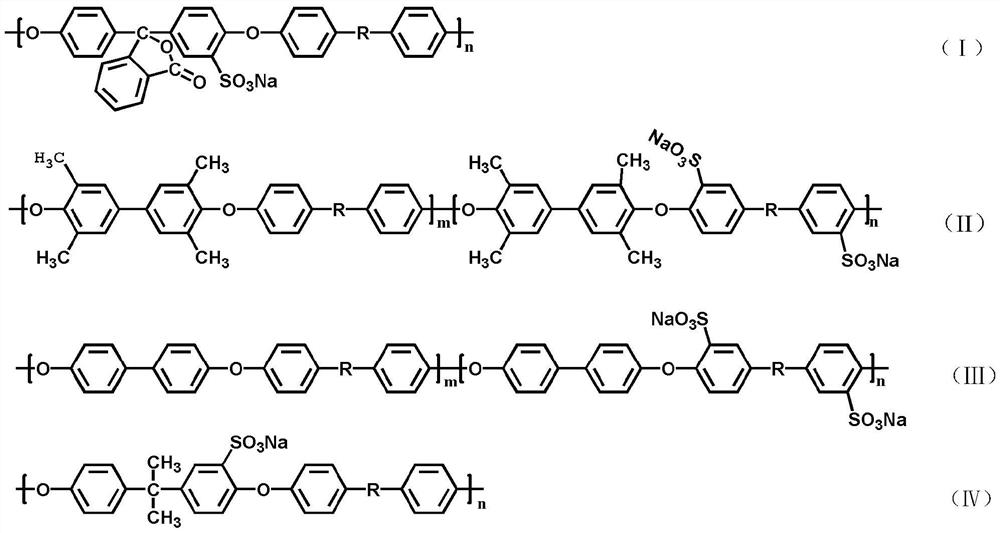

[0039] 2kg of polypropylene (F1002B, Sinopec Yangzi Petrochemical) was stretched into a porous film (the average pore size of the porous film is 2 microns) on a film uniaxial stretching machine (Guangzhou Putong, MESI-LL). Add 5 g of sulfonated polyethersulfone (number average molecular weight: 65,000, ion exchange capacity: 1.86) having the structure of formula (I) into 95 g of formic acid and fully dissolve. Add 2.1g of lithium chloride and 0.2g of nano-zinc oxide into the obtained solution, and stir well until the mixture is uniform. The solution was evenly brushed on one surface of the polypropylene porous film, then placed in an oven, and dried at 70° C. for 10 minutes to obtain a gas-barrier and moisture-permeable film (A1). Wherein, the thickness of the polypropylene supporting layer is 25 microns, and the thickness of the functional layer is 10 microns.

Embodiment 2

[0041] 2kg of polypropylene (F1002B, Sinopec Yangzi Petrochemical) was stretched into a porous film (the average pore size of the porous film is 2 microns) on a film uniaxial stretching machine (Guangzhou Putong, MESI-LL). Add 7g of sulfonated polyethersulfone (number-average molecular weight: 58,000, ion exchange capacity: 2.10) having the structure of formula (II) into 93g of ethylene glycol monomethyl ether, and fully dissolve it. Add 1.4g of lithium fluoride and 0.2g of nano-zinc oxide (Bahringwei, 99.5%, particle size 10-30nm) into the obtained solution, and fully stir until mixed evenly. Brush this solution evenly on one surface of the polypropylene porous film, then place it in an oven, and dry it at 70° C. for 10 minutes to obtain a gas-barrier and moisture-permeable film (A2). Wherein, the thickness of the polypropylene supporting layer is 25 microns, and the thickness of the functional layer is 12 microns.

Embodiment 3

[0043] 2kg of polypropylene (F1002B, Sinopec Yangzi Petrochemical) was stretched into a porous film (the average pore size of the porous film is 2 microns) on a film uniaxial stretching machine (Guangzhou Putong, MESI-LL). Add 9g of sulfonated polyethersulfone (number-average molecular weight: 80,000, ion exchange capacity: 1.67) having the structure of formula (III) into 91g of N,N-dimethylformamide, and fully dissolve it. Add 2.7g of attapulgite (Bailingwei, 10nm in diameter and 1 micron in length) and 0.2g of nano-zinc oxide (Bailingwei, 99.5%, 10-30nm in particle size) into the obtained solution, and stir until they are evenly mixed. Brush this solution evenly on one surface of the polypropylene porous film, then place it in an oven, and dry it at 70° C. for 10 minutes to obtain a gas-barrier and moisture-permeable film (A3). Wherein, the thickness of the polypropylene support layer is 25 microns, and the thickness of the functional layer is 13 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com