A kind of preparation method of aluminum silicon carbide electronic packaging box body connector hole

An aluminum silicon carbide and electronic packaging technology, which is applied in the direction of electric solid devices, semiconductor/solid device manufacturing, semiconductor devices, etc., can solve problems such as cracking, microcracks, and affecting the airtightness of the packaging box, and achieve good mechanical properties. No microscopic cracks at the interface, and the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

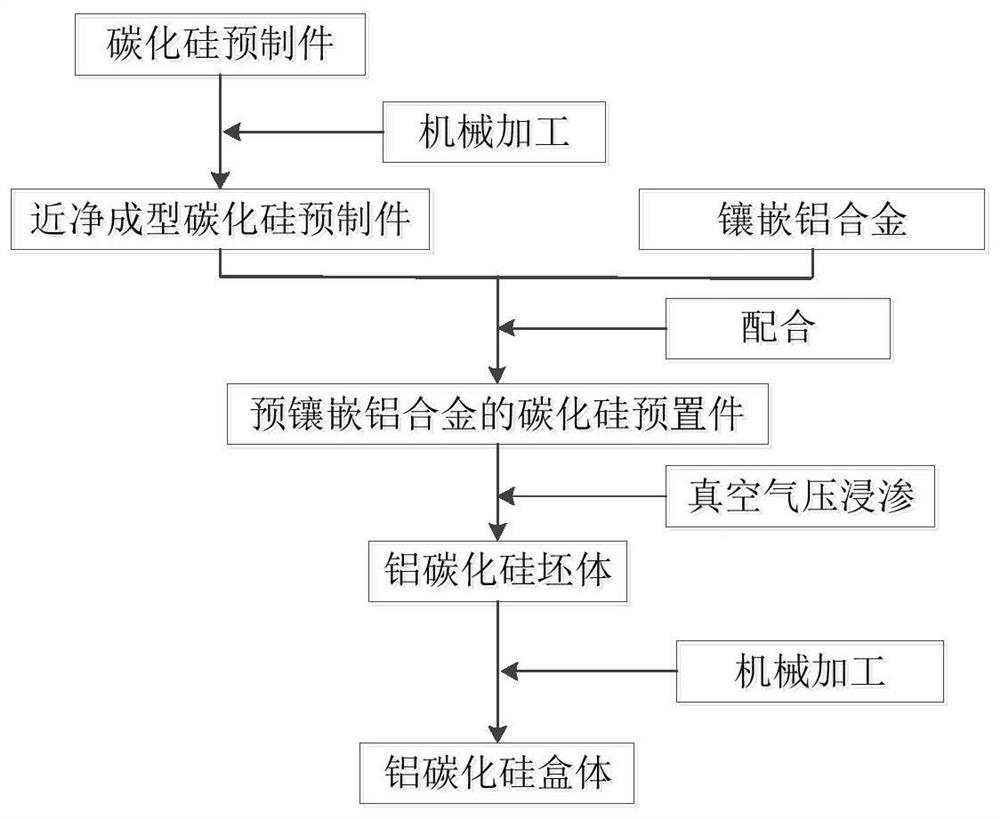

[0036] The invention provides a method for preparing an electrical connector hole of an aluminum silicon carbide box to effectively solve the problem of machining the electrical connector hole of an aluminum silicon carbide box. The technical solution is to inlay aluminum alloy at the position where the electrical connector hole needs to be processed on the aluminum silicon carbide box body. On the one hand, the aluminum alloy has a soft texture and is suitable for conventional machining; on the other hand, the interface between the inlaid aluminum alloy and the aluminum silicon carbide box is continuous without micro-crack defects, which ensures the airtightness of the packaging box.

[0037] Preferably, the inlaid aluminum alloy can be a particle-reinforced aluminum alloy or a spray-deposited aluminum-silicon alloy, wherein the particle-reinforced aluminum alloy reinforcement particles are aluminum alloy powder with a particle size of 10-200 μm, which can be selected accordin...

Embodiment 1

[0039] Attached below figure 1 for further clarification.

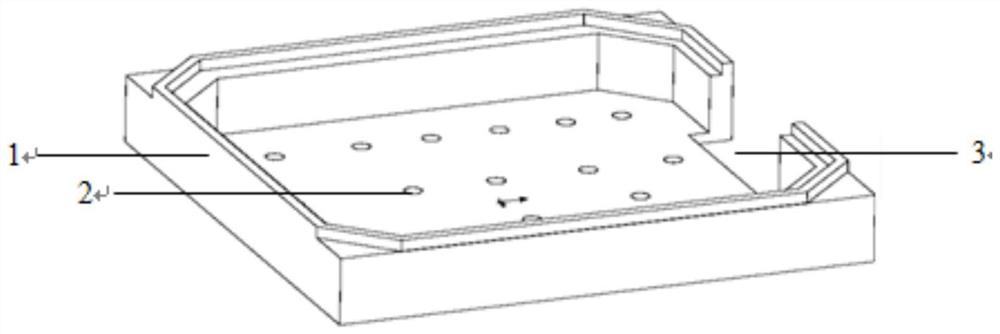

[0040] In this embodiment, the aluminum silicon carbide box structure with the electrical connector hole is as follows Figure 4 As shown, the inlaid aluminum alloy 15 constituting the electrical connector hole is composed of 6063 aluminum alloy particle powder and ZL101A aluminum alloy matrix as the reinforcing phase. After the square notch and cylindrical through hole are filled with 6063 aluminum alloy particle powder, the notch and through hole are filled with ZL101A aluminum alloy solution, and after cooling, the inlaid aluminum alloy 15 is formed, in which the volume fraction of 6063 aluminum alloy powder The volume fraction of the ZL101A aluminum alloy matrix is 30%, and its proportion can be adjusted according to the actual application. The aluminum silicon carbide box 16 is composed of silicon carbide particles and a ZL101A aluminum alloy matrix, wherein the volume fraction of silicon carbide is 63%, and ...

Embodiment 2

[0048] The structure of the aluminum silicon carbide box body with the electrical connector hole of the present embodiment is as follows: Figure 4 As shown, the inlaid aluminum alloy 15 constituting the hole of the electrical connector is a spray-deposited aluminum-silicon alloy, wherein the content of silicon is 27%, and the content of aluminum is 73%. The aluminum silicon carbide box 16 is composed of silicon carbide particles and Zl102 aluminum alloy matrix, wherein the volume fraction of silicon carbide is 63%, and the volume fraction of Zl102 aluminum alloy is 37%.

[0049] Concrete preparation steps are as follows:

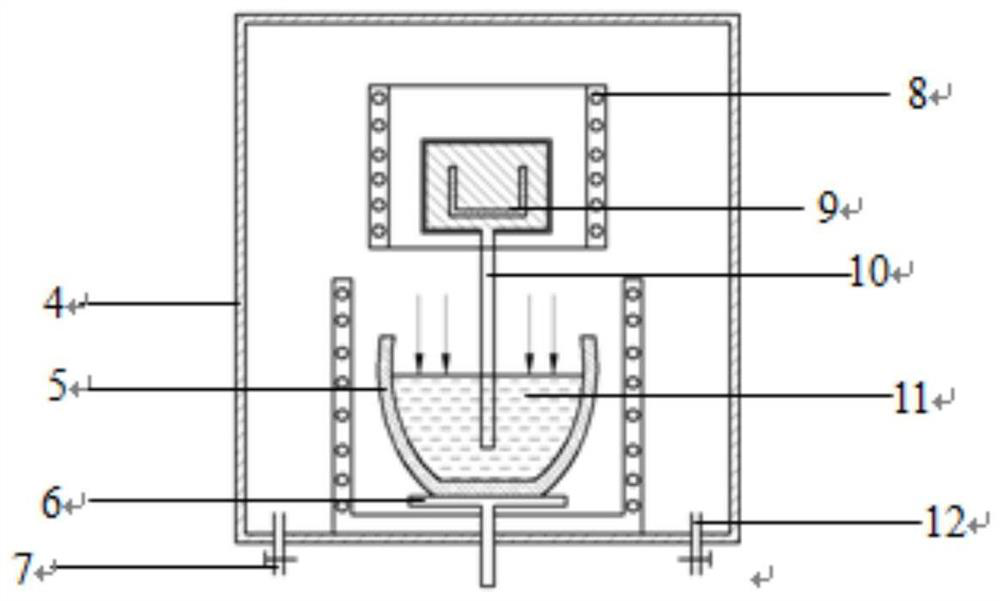

[0050] 1) Preparation of near-net-shaped silicon carbide preforms. First, with reference to the size of the final product, the rough outline of the silicon carbide preform 1 is processed; then, referring to the size of the electrical connector hole 14, a square notch 3 is processed on the silicon carbide preform 1 as a position for inlaying aluminum alloy,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com