Coating for improving spheroidal graphite casting mechanical performance

A technology of mechanics and performance, applied in casting molding equipment, coatings, molds, etc., can solve the problems of high price, lingering performance of casting coatings, low operability, etc., to improve casting mechanical properties, improve mechanical properties, pearlescent The effect of increasing body mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

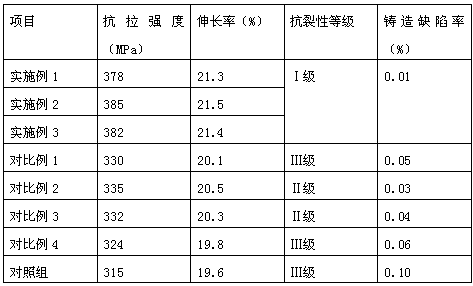

Embodiment 1

[0014] A coating for improving the mechanical properties of ductile graphite casting, which is made of the following components in parts by weight: 65 parts of refractory powder, 1.5 parts of mixed suspending agent, 1.0 part of phenolic resin, 0.5 part of ethyl silicate, 15 parts of ethanol, carboxymethyl 0.4 parts of sodium cellulose, 0.3 parts of ethyl cellulose;

[0015] The preparation method is: add the mixed suspending agent into the reactor, heat to 50°C, stir for 20 minutes, add refractory powder and ethanol solution, slowly raise the temperature to 75°C, add phenolic resin, ethyl silicate, carboxymethyl Sodium cellulose and ethyl cellulose are dissolved and homogenized, added to the reactor, kept for 500 minutes, cooled to 40°C, ground and homogenized, stirred evenly, discharged when the temperature reaches 30°C, and packaged.

[0016] As a further improvement to the above scheme, the refractory powder contains the following components in terms of mass percentage: sil...

Embodiment 2

[0020] A coating for improving the mechanical properties of ductile graphite casting, which is made of the following components in parts by weight: 68 parts of refractory powder, 1.8 parts of mixed suspending agent, 1.1 parts of phenolic resin, 0.6 parts of ethyl silicate, 18 parts of ethanol, carboxymethyl 0.5 parts of sodium cellulose, 0.4 parts of ethyl cellulose;

[0021] Its preparation method is: add the mixed suspending agent into the reactor, heat to 55°C, stir for 25 minutes, add refractory powder and ethanol solution, slowly raise the temperature to 76°C, add phenolic resin, ethyl silicate, carboxymethyl Sodium cellulose and ethyl cellulose were dissolved and homogenized, added to the reactor, kept for 55 minutes, cooled to 45°C, ground and homogenized, stirred evenly, discharged when the temperature reached 32°C, and packaged.

[0022] As a further improvement to the above scheme, the refractory powder contains the following components in terms of mass percentage: s...

Embodiment 3

[0026] A coating for improving the mechanical properties of ductile graphite casting, which is made of the following components in parts by weight: 70 parts of refractory powder, 2.0 parts of mixed suspending agent, 1.2 parts of phenolic resin, 0.7 parts of ethyl silicate, 20 parts of ethanol, carboxymethyl 0.6 parts of sodium cellulose, 0.5 parts of ethyl cellulose;

[0027] The preparation method is as follows: add the mixed suspending agent into the reactor, heat to 60°C, stir for 30 minutes, add refractory powder and ethanol solution, slowly raise the temperature to 78°C, add phenolic resin, ethyl silicate, carboxymethyl Sodium cellulose and ethyl cellulose are dissolved and homogenized, added to the reactor, kept for 60 minutes, cooled to 50°C, ground and homogenized, stirred evenly, discharged when the temperature reaches 35°C, and packaged.

[0028] As a further improvement to the above scheme, the refractory powder contains the following components in terms of mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com