Novel cladding alloy powder material with controllable thermal expansion and manufacturing method thereof

A technology for cladding alloys and powder materials, which is applied in the coating process and coating of metal materials, can solve problems such as cracks in cladding materials, achieve the effects of reducing thermal stress, simple preparation method, and reducing crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

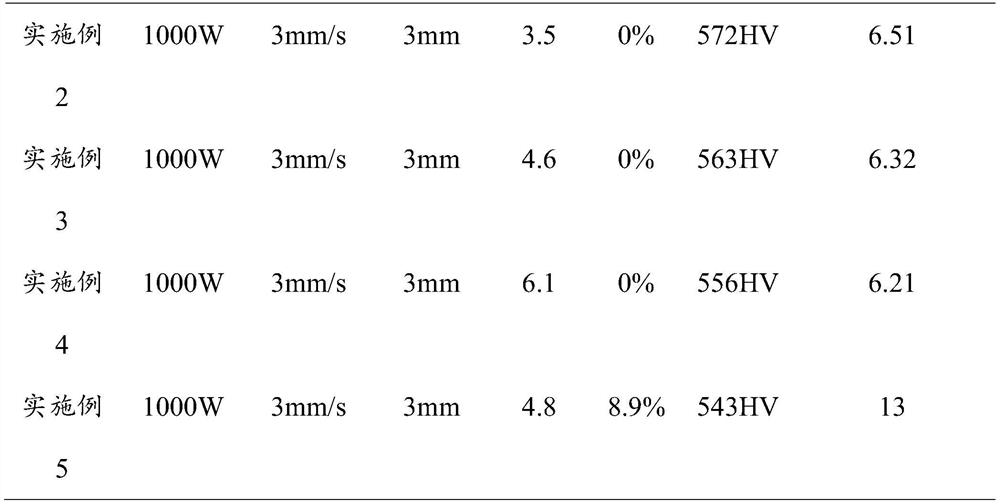

Examples

preparation example Construction

[0023] A method for preparing a new cladding alloy powder with controllable thermal expansion, comprising the following steps: using a planetary ball mill to mix the above powder, setting the mixing time of the ball mill to 90-120 minutes, and the speed to 90-120r / min for powder mixing , to obtain a new cladding alloy powder material with controllable thermal expansion.

[0024] A method for preparing a new cladding alloy cladding layer with controllable thermal expansion, which meets the following steps:

[0025] (1) The new cladding alloy powder with controllable thermal expansion is uniformly mixed with absolute ethanol and preset on the 42CrMo matrix.

[0026] (2) Under the protection of high-purity argon gas, the cladding layer is formed by using a fiber laser.

[0027] In some embodiments, before the step (1), the substrate needs to be polished with coarse sandpaper to remove impurities such as rust and oil.

[0028] In some embodiments, the thickness of the preset pow...

Embodiment 1

[0036] The laser cladding composite powder of this embodiment is composed as follows by volume percentage: 30% ZrW 2 o 8 +70%NiCrBSi; matrix is 42CrMo.

[0037] The method of using the above raw material components to produce new cladding alloy powder and cladding layer with controllable thermal expansion for laser cladding is as follows:

[0038] Step 1: Put the mixed powder into a planetary ball mill, grind the above composite powder with alumina grinding balls, set the ball-to-material ratio to 3:1, the mixing time to 320min, and the speed of the ball mill to 120r / min. After powder mixing, use a drying oven for drying treatment. The temperature of the drying oven is set at 110°C, and the drying time is 320 minutes. After drying, a new type of cladding alloy powder with controllable thermal expansion for laser cladding is obtained.

[0039]Step 2: Use prefabricated powder spreading method, the thickness of the powder layer is 0.8mm-1mm.

[0040] Step 3: During laser cl...

Embodiment 2

[0042] The composition of the laser cladding composite powder in this embodiment is as follows by volume percentage:

[0043] 40%ZrW 2 o 8 +60%NiCrBSi

[0044] The matrix is 42CrMo.

[0045] The method for preparing a new type of cladding alloy powder and cladding layer with controllable thermal expansion for laser cladding is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com