Crackless yttrium hydride neutron moderation material for space reactor and preparation method of crack-free yttrium hydride neutron moderation material

A crack-free, yttrium hydride technology, applied in transition element hydrides, moderators/core structures, reactors, etc., to achieve the effect of improving hydrogen atom density, excellent mechanical properties and processing performance, and avoiding thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

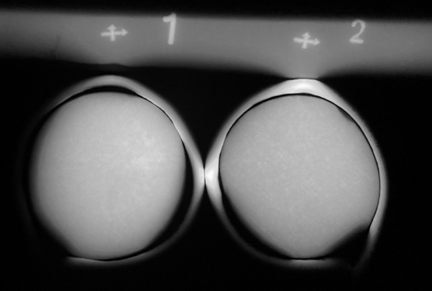

[0025] The crack-free yttrium hydride neutron moderator material of this embodiment is composed of the following elements by mass: the total mass percentage of Y and H is 99.00%, and the mass percentage of H is 1.83%, and the rest are unacceptable Avoid impurities.

[0026] The preparation method of the crack-free yttrium hydride neutron moderator material of the present embodiment comprises the following steps:

[0027] Step 1. Select yttrium metal powder with a mass purity of 99.5% and form it into a designed shape by cold pressing to obtain a pressed metal yttrium blank; The time is 3min;

[0028] Step 2, put the metal yttrium pressed blank obtained in the step 1 into a molybdenum boat, then place it in a high temperature hydrogenation furnace as a whole, and evacuated to a vacuum degree of 10 -2 After Pa, into the high-temperature hydrogenation furnace at a flow rate of 0.1 L / min, hydrogen with a mass purity of 99.95% was introduced for sintering, and the hydrogen pressu...

Embodiment 2

[0033] The crack-free yttrium hydride neutron moderator material of this embodiment is composed of the following elements by mass: the total mass percentage of Y and H is 99.2%, and the mass percentage of H is 2.02%, and the rest are unacceptable Avoid impurities.

[0034] The preparation method of the crack-free yttrium hydride neutron moderator material of the present embodiment comprises the following steps:

[0035] Step 1. Select yttrium metal powder with a mass purity of 99.5% and form it into a designed shape by cold pressing to obtain a pressed metal yttrium blank; The time is 6min;

[0036] Step 2, put the metal yttrium pressed blank obtained in the step 1 into a molybdenum boat, then place it in a high temperature hydrogenation furnace as a whole, and evacuated to a vacuum degree of 10 -1 After Pa, pass hydrogen with a mass purity of 99.95% into the high-temperature hydrogenation furnace at a flow rate of 0.5 L / min, and then sinter, and ensure that the hydrogen pre...

Embodiment 3

[0039] The crack-free yttrium hydride neutron moderator material of this embodiment is composed of the following elements by mass: the total mass percentage of Y and H is 99.20%, and the mass percentage of H is 2.03%, and the rest are unacceptable Avoid impurities.

[0040] The preparation method of the crack-free yttrium hydride neutron moderator material of the present embodiment comprises the following steps:

[0041] Step 1. Select yttrium metal powder with a mass purity of 99.5% and form it into a designed shape by cold pressing to obtain a pressed metal yttrium blank; The time is 10min;

[0042] Step 2, put the metal yttrium pressed blank obtained in the step 1 into a molybdenum boat, then place it in a high temperature hydrogenation furnace as a whole, and evacuated to a vacuum degree of 10 -2 After Pa, feed hydrogen with a mass purity of 99.99% into the high-temperature hydrogenation furnace at a flow rate of 0.8 L / min, and then sinter, and ensure that the hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com