Hydrothermal preparation method and product of superconducting single crystal film

A superconducting film and superconducting technology, applied in the field of materials, can solve the problems of inability to grow high-temperature and easily decomposed thin-film materials, high cost, high pollution, etc. The method is simple, efficient and easy to promote, the shape and size are not limited, and the film-forming area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

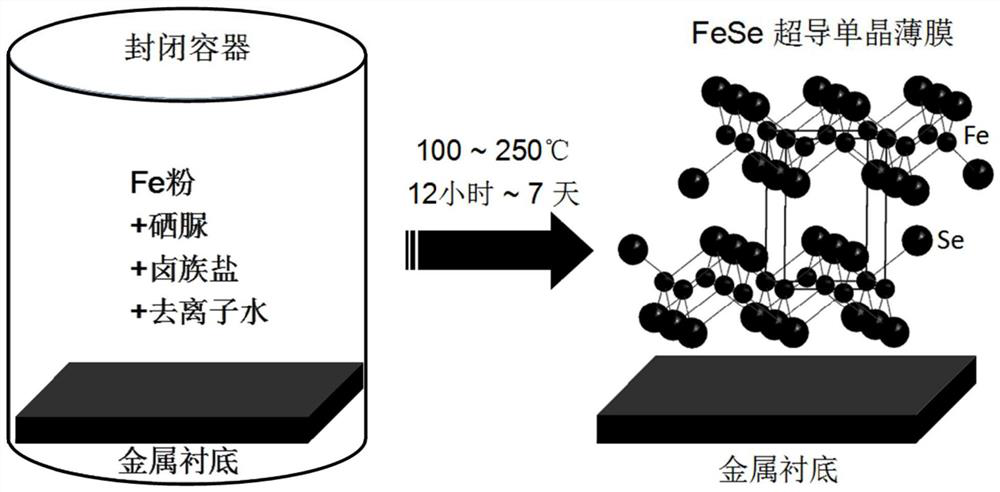

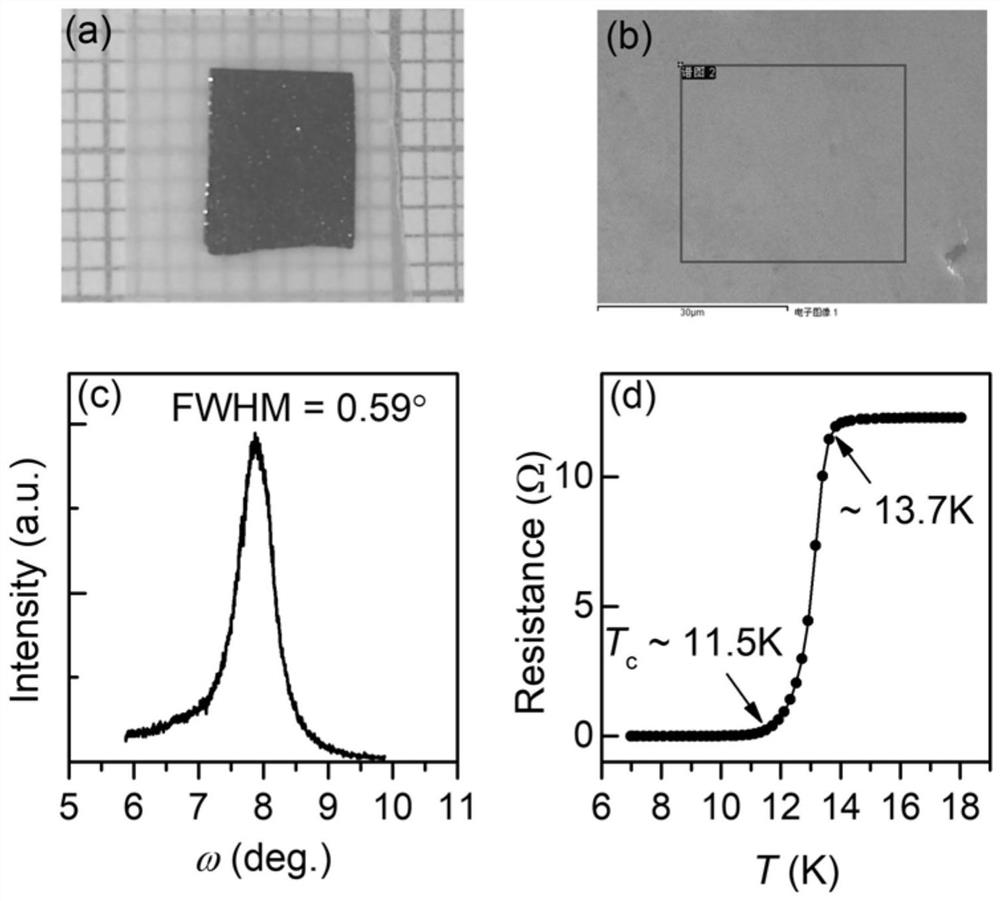

[0043] The present examples serve to illustrate the metal substrate by the growth of high quality single crystal thin film FeSe soft chemistry.

[0044] Table reaction conditions for growing a single crystal thin film FeSe

[0045]

[0046]

[0047] Specifically, the following steps:

[0048] (A) 0.01 mol of urea selenium, iron 0.02 mol, catalyst and NaF 0.03mol 5ml of deionized water, heating the vessel charged with a closable, sufficiently mixed with stirring with a glass rod and placed in a metal substrate polished FeTe. All reagents were purchased from AlfaAesar Corporation, purity higher than 4N.

[0049] (B) the closed container is then sealed, placed in an oven at a rate of 2 ℃ / min from room temperature to 130. deg.] C, reacted at this temperature for seven days, and then incubated stopped, cooled to room temperature.

[0050] After (c) the reaction, remove the metal substrate to open the closed container, and washed repeatedly with deionized water to obtain a single ...

Embodiment 16~27

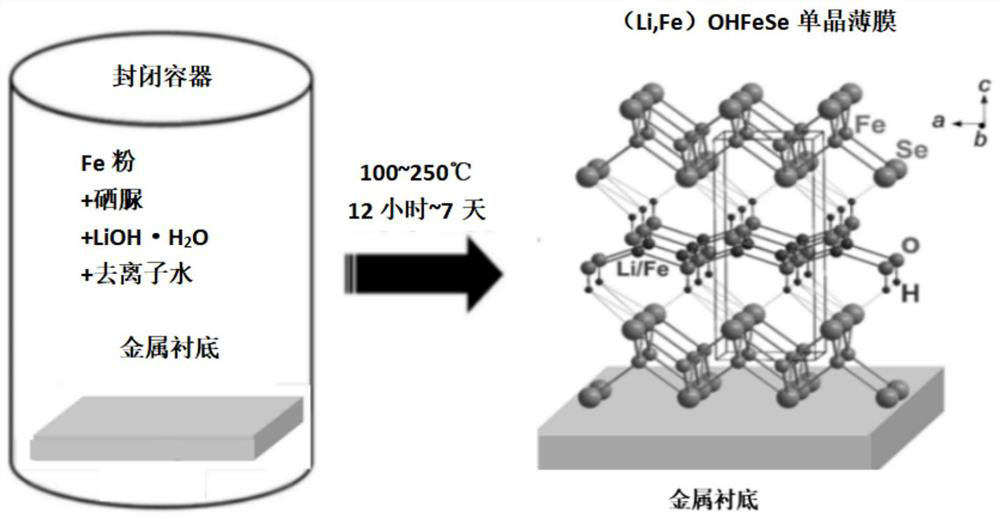

[0058] Examples for explaining the present embodiment on a substrate by a metal (Li, Fe) OHFeSe growth of high quality single crystal thin film of soft chemistry.

[0059] Table 3 Reaction conditions of growth (Li, Fe) OHFeSe single crystal thin film

[0060]

[0061] (A) the selenourea 0.01mol, iron 0.015mol, LiOH · H 2 O0.01mol and 5ml of deionized water, may be charged with a closed heating vessel and stirred thoroughly mixed with a glass rod and placed in a metal substrate polished FeTe. All reagents were purchased from AlfaAesar Corporation, purity higher than 4N.

[0062] (B) the closed container is then sealed, placed in an oven at a rate of 2 ℃ / min from room temperature to 130. deg.] C, reacted at this temperature for seven days, and then incubated stopped, cooled to room temperature.

[0063] After (c) the reaction, remove the metal substrate to open the closed container, and washed repeatedly with deionized water to obtain a (Li, Fe) OHFeSe superconducting single cry...

Embodiment 28-32

[0071] Similar procedure as in Example 1-27, it can be used for the growth of the transition metal dichalcogenide film MX 2 Wherein, M being a transition metal Ti, Nb, Ta, Mo, W; X is a chalcogen S, Se, Te, specific reactants and conditions are shown in Table 5.

[0072] The transition metal disulfide Table 5 were prepared under different reaction conditions chalcogenide film MX 2

[0073]

[0074]

[0075] Doping substance chalcogen may require only provide the desired chalcogen hydrothermal reaction, the reagent is not required to be, the substrate may be adjusted according to actual conditions, including various types of a single crystal or an alloy , only smooth the surface of the substrate, and does not participate in the hydrothermal reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com