Preparation method of porous Si/SiC/C material and negative electrode material

A technology of silicon powder and powder, which is applied in the field of porous Si/SiC/C material preparation, can solve the problems of complex process, difficult to guarantee the thickness and uniformity of silicon carbide layer, etc., and achieve low cost, huge environmental benefits and Economic benefits, the effect of solving the problem of garbage disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

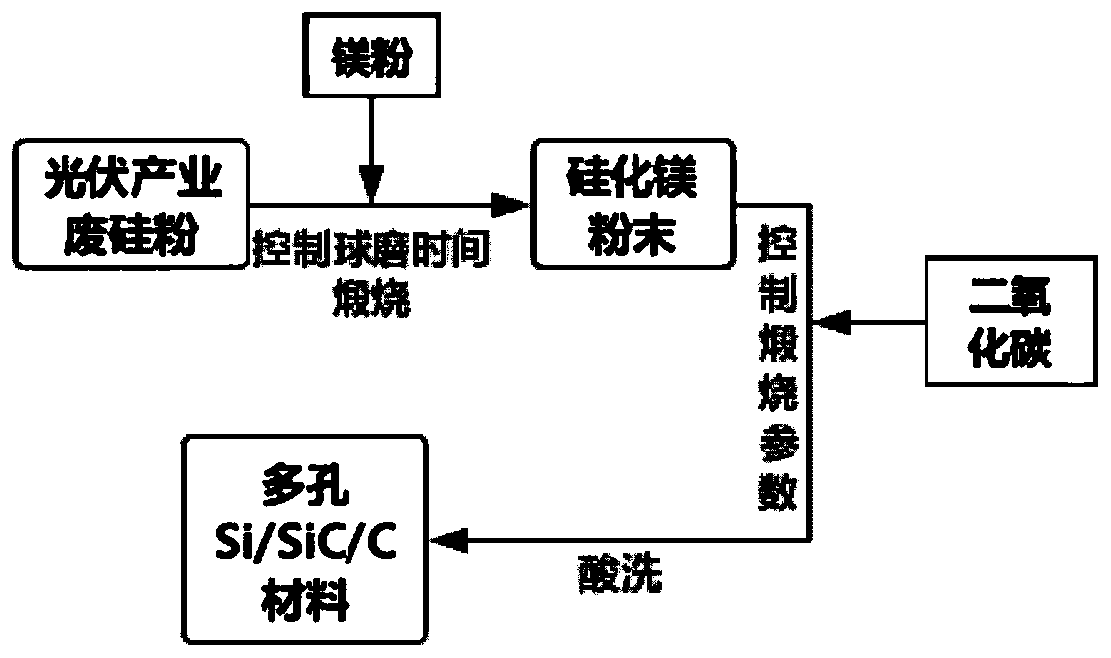

[0052] refer to figure 1 The process flow in prepares porous Si / SiC / C material, specifically as follows:

[0053] S1. Grinding and mixing 1g of silicon powder and 1.8g of magnesium powder, the mixture and 10ml of absolute ethanol were placed in a planetary ball mill for physical ball milling for 24 hours, and dried to obtain a silicon-magnesium alloy powder;

[0054] S2. In a nitrogen atmosphere, put the silicon-magnesium alloy powder in a crucible, place it in an atmosphere sintering furnace, raise the temperature to 550°C at a rate of 3°C / min, keep it for 5 hours, cool it with the furnace, and grind it to obtain the described Magnesium silicide powder;

[0055] S3. Put the magnesium silicide powder in a crucible, place it in an atmosphere sintering furnace, and then 2 , heat up to 650°C at a rate of 10°C / min, keep warm for 1 hour, cool in the furnace, grind, pickle with 1mol / L hydrochloric acid aqueous solution, then pickle with 1wt% hydrofluoric acid aqueous solution and ...

Embodiment 2

[0061] To prepare a lithium ion battery, the porous Si / SiC / C material prepared in Example 1 was used as an active material to make a button half battery (CR-2025). The steps include: mixing 60wt% active material, 20wt% Super P and 20wt% sodium alginate binder to form a uniform slurry; pasting the obtained slurry on a copper foil, vacuum drying in an oven at 100°C for 12h, and then Punch the copper foil into a disc. The half-cells were assembled in a glove box filled with argon, using pure lithium foil as the counter electrode, and a porous membrane (Celgard2400) as the separator.

Embodiment 3

[0063] The button half-cell (CR-2025) prepared in Example 2 was used to conduct an electrochemical test at room temperature within a voltage window of 0.01V-1.5V. see test results Figure 5 , Figure 6 .

[0064] From Figure 5 It can be seen that the first discharge specific capacity of the battery is 903mAh / g at a current density of 400mA / g. After the first 20 cycles, the specific capacity retention rate is greater than or equal to 90%; after 100 cycles, the specific capacity is 594mAh / g. g, with better cycle performance.

[0065] From Figure 6 It can be seen that the battery exhibits a relatively stable rate performance. Under the current density of 3A / g, the specific discharge capacity remained at 617mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com