High-sensitivity negative capacitance field effect transistor photoelectric detector and preparation method

A technology of photodetectors and capacitive fields, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as large dark current, complex preparation process of quantum dot material size and quality control, low detection rate, etc. current, improve photodetection efficiency, and suppress dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

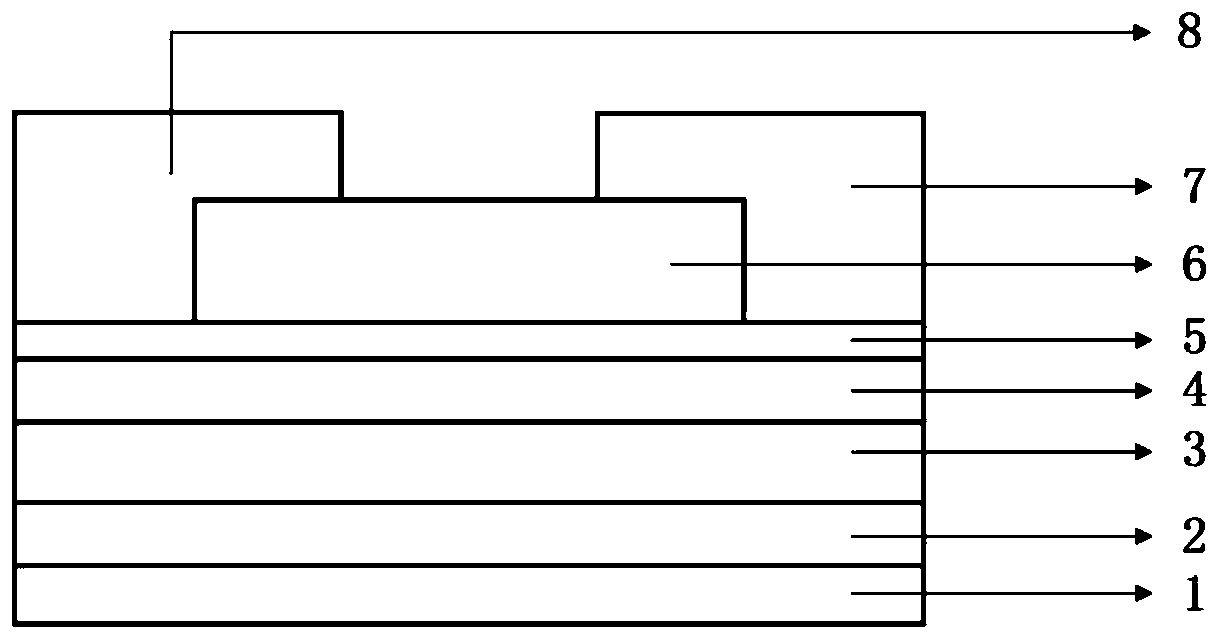

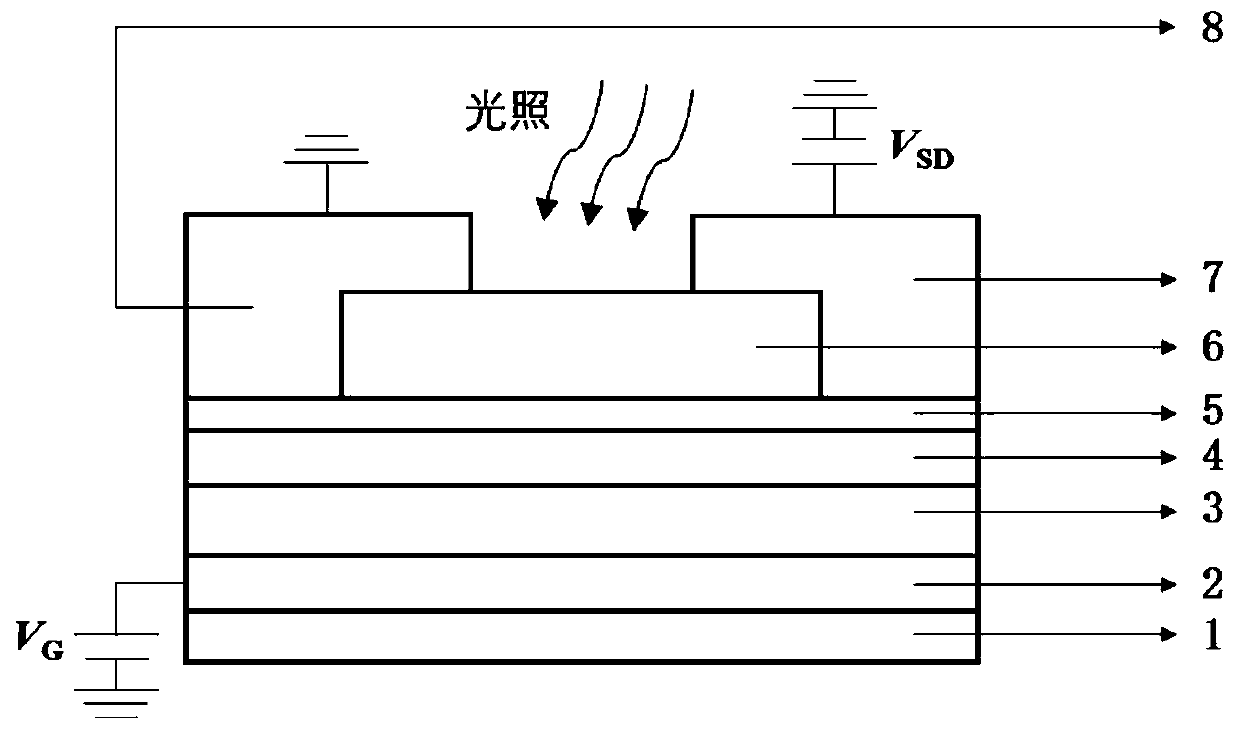

[0064] In this embodiment, a low-dimensional material phototransistor device under the control of a hafnium oxide-based ferroelectric film is provided. The cross-sectional view of the device is as follows figure 1 shown.

[0065] From bottom to top, the detector is as follows: 1 substrate, 2 oxide, 3 gate electrode, 4 hafnium oxide-based ferroelectric gate dielectric with negative capacitance effect, 5 oxide gate dielectric, 6 low-dimensional semiconductor material, 7 metal source electrodes with 8 metal drain electrodes.

[0066] In this embodiment, substrate 1 is a P-type doped silicon substrate; oxide layer 2 is silicon dioxide with a thickness of 285 nanometers; gate electrode 3 is titanium nitride with a thickness of 40 nanometers; hafnium oxide with negative capacitance effect The base ferroelectric grid dielectric 4 is zirconium-doped hafnium oxide, and the molecular formula is Hf 0.5 Zr 0.5 o 2 , with a thickness of 10 nanometers; the oxide gate dielectric 5 is alu...

Embodiment 2

[0071] In this embodiment, a low-dimensional material phototransistor device under the control of a hafnium oxide-based ferroelectric film is provided. The cross-sectional view of the device is as follows figure 1 shown.

[0072] From bottom to top, the detector is as follows: 1 substrate, 2 oxide, 3 gate electrode, 4 hafnium oxide-based ferroelectric gate dielectric with negative capacitance effect, 5 oxide gate dielectric, 6 low-dimensional semiconductor material, 7 metal source electrodes with 8 metal drain electrodes.

[0073] In this embodiment, substrate 1 is a P-type doped silicon substrate; oxide layer 2 is silicon dioxide with a thickness of 270 nanometers; gate electrode 3 is titanium nitride with a thickness of 30 nanometers; hafnium oxide with negative capacitance effect The ferroelectric gate dielectric 4 is yttrium-doped hafnium oxide, and its molecular formula is Hf 0.93 Y 0.07 o 2 , with a thickness of 10 nanometers; the oxide gate dielectric 5 is aluminum ...

Embodiment 3

[0078] In this embodiment, a low-dimensional material phototransistor device under the control of a hafnium oxide-based ferroelectric film is provided. The cross-sectional view of the device is as follows figure 1 shown.

[0079] From bottom to top, the detector is as follows: 1 substrate, 2 oxide, 3 gate electrode, 4 hafnium oxide-based ferroelectric gate dielectric with negative capacitance effect, 5 oxide gate dielectric, 6 low-dimensional semiconductor material, 7 metal source electrodes with 8 metal drain electrodes.

[0080] In this embodiment, the substrate 1 is a P-type doped silicon substrate; the oxide layer 2 is silicon dioxide with a thickness of 300 nm; the gate electrode 3 is titanium nitride with a thickness of 50 nm; The ferroelectric gate dielectric 4 is zirconium-doped hafnium oxide, the molecular formula is Hf 0.5 Zr 0.5 o 2 , with a thickness of 5nm; the oxide gate dielectric 5 is aluminum oxide, prepared by atomic layer deposition, with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com