Method for preparing TC21 titanium alloy gradient structure with high strength and toughness

A TC21, gradient microstructure technology, applied in the field of alloy materials, can solve the problems of difficulty in preparing small samples, complex preparation process, and difficult operation, and achieve the effect of large-scale industrial promotion value, simple operation, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

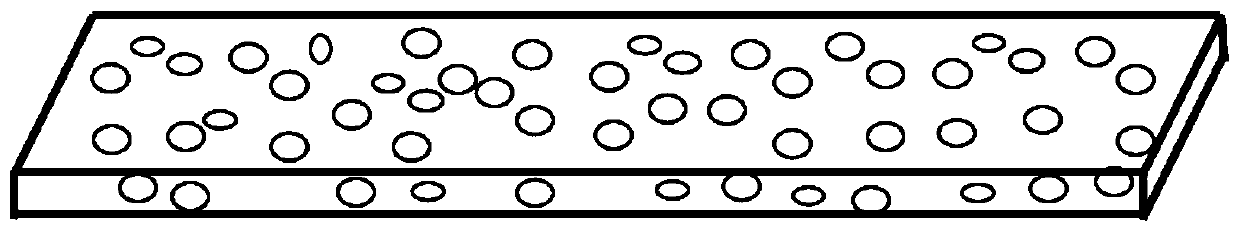

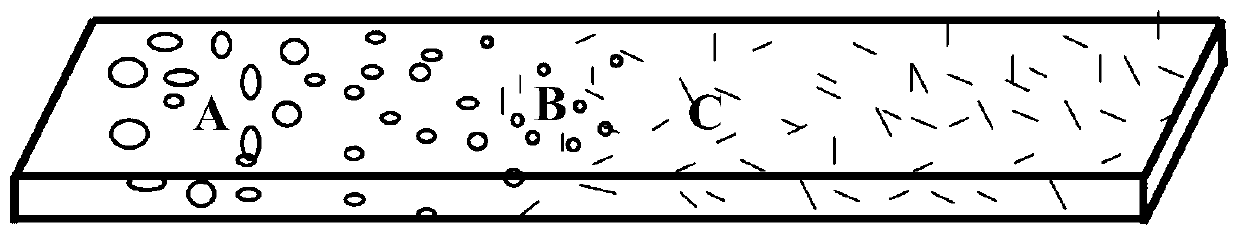

[0039] (1) Select a TC21 titanium alloy plate-shaped sample with a length of about 80 mm, and use metallographic sandpaper to polish the surface of the plate-shaped titanium alloy sample; then use absolute ethanol to moisten the absorbent cotton to wipe the sample, and dry it for later use, as figure 1 shown;

[0040] (2) Connect the plate sample to the positive and negative copper plate electrodes of the pulse power supply, and put it into the glove box;

[0041] (3) vacuumize the glove box, the vacuum degree is 4KPa, then fill the glove box with an argon atmosphere, keep the air pressure at 80KPa, to prevent the sample from being oxidized;

[0042] (4) Turn on the pulse power supply, turn on the pulse power switch, adjust the pulse voltage to 67V, the pulse current to 78A, and the pulse frequency to 550Hz. The heating time is 1 minute, and the real-time temperature is tested by an infrared thermometer, kept at 1000°C for 5 minutes, and then air-cooled to room temperature; ...

Embodiment 2

[0046] (1) Select a TC21 titanium alloy round bar sample with a diameter of 11 mm and a length of about 80 mm, first process it into a round bar shape by a lathe, and then polish the surface of the sample with metallographic sandpaper; then use absolute ethanol to moisten the absorbent cotton to wipe the sample, and dried for later use, such as Figure 4 shown;

[0047] (2) Connect the sample to be heat treated with the positive and negative copper plate electrodes of the pulse power supply, and put it into the glove box;

[0048] (3) Vacuumize the glove box, and the vacuum degree is 4KPa, then pass the argon atmosphere into the glove box, keep the air pressure at 80KPa, protect the sample to be heat-treated, and prevent it from being oxidized;

[0049] (4) Turn on the power and turn on the pulse power switch. Adjust the pulse voltage to 75V, the pulse current to 80A, and the pulse frequency to 600Hz. The heating time is 1.5 minutes, and the real-time temperature is measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com