Rubber-plastic alloy material with excellent oil and corrosion resistance, and preparation method thereof

A rubber-plastic alloy and corrosion-resistant technology, applied in the field of rubber-plastic alloy materials, can solve the problems of rubber-plastic alloy performance constraints, influence on popularization and application, and easy to produce brittleness, etc., achieve excellent oil resistance and corrosion resistance, avoid agglomeration, and increase bonding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

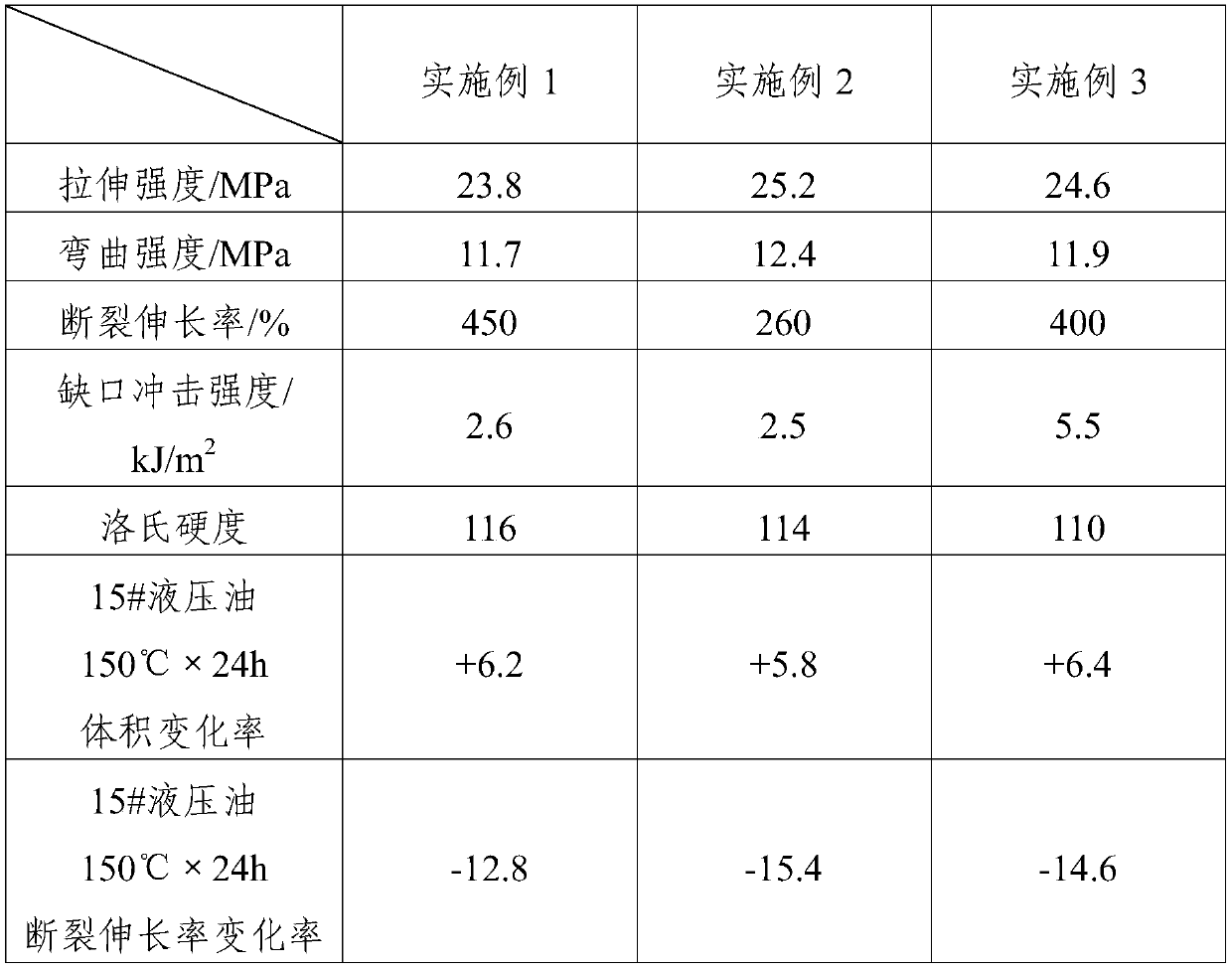

Examples

Embodiment 1

[0032] A rubber-plastic alloy material with excellent oil resistance and corrosion resistance, comprising the following components in parts by weight:

[0033] 45 parts of hydrogenated nitrile rubber, 30 parts of epoxy-solution polystyrene butadiene rubber, 10 parts of trans-1,4-polyisoprene, 85 parts of bisphenol A polycarbonate, vinyl-terminated methylbenzene 12 parts of base silicone oil, 8 parts of bis(2-ethylhexyl) phthalate, 10 parts of diaminopolyethylene glycol, 22 parts of polydopamine surface modified nano-silica, graphene / polyimide composite reinforcement 14 parts of fiber, 13 parts of sulfur, 1 part of vulcanization accelerator, 5 parts of stearic acid, 4 parts of microcrystalline paraffin, 1.2 parts of anti-aging agent, and 2 parts of flame retardant.

[0034] The preparation method of epoxidized solution-polymerized styrene-butadiene rubber is as follows:

[0035] Add solution-polymerized styrene-butadiene rubber into cyclopentane, the mass ratio of solution-pol...

Embodiment 2

[0043] A rubber-plastic alloy material with excellent oil resistance and corrosion resistance, comprising the following components in parts by weight:

[0044] 60 parts of hydrogenated nitrile rubber, 20 parts of epoxy-solution polystyrene butadiene rubber, 10 parts of trans-1,4-polyisoprene, 100 parts of bisphenol A polycarbonate, vinyl-terminated methylbenzene 15 parts of base silicone oil, 5 parts of bis(2-ethylhexyl) phthalate, 10 parts of diaminopolyethylene glycol, 22 parts of polydopamine surface modified nano-silica, graphene / polyimide composite reinforcement 15 parts of fiber, 20 parts of sulfur, 2 parts of vulcanization accelerator, 3 parts of stearic acid, 2 parts of microcrystalline paraffin, 1 part of anti-aging agent, and 1 part of flame retardant.

[0045] The preparation method of epoxidized solution-polymerized styrene-butadiene rubber is as follows:

[0046] Add solution-polymerized styrene-butadiene rubber into cyclopentane, the mass ratio of solution-polym...

Embodiment 3

[0054] A rubber-plastic alloy material with excellent oil resistance and corrosion resistance, comprising the following components in parts by weight:

[0055] 40 parts of hydrogenated nitrile rubber, 26 parts of epoxy-solution polystyrene butadiene rubber, 20 parts of trans-1,4-polyisoprene, 85 parts of bisphenol A polycarbonate, vinyl-terminated methylbenzene 10 parts of base silicone oil, 8 parts of bis(2-ethylhexyl) phthalate, 10 parts of diaminopolyethylene glycol, 25 parts of polydopamine surface modified nano-silica, graphene / polyimide composite reinforcement 16 parts of fiber, 10 parts of sulfur, 1 part of vulcanization accelerator, 4 parts of stearic acid, 2 parts of microcrystalline paraffin, 1 part of anti-aging agent, 2 parts of flame retardant.

[0056] The preparation method of epoxidized solution-polymerized styrene-butadiene rubber is as follows:

[0057] Add solution-polymerized styrene-butadiene rubber into cyclopentane, the mass ratio of solution-polymerize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com