Water-based anticorrosive primer and preparation method thereof

An anti-corrosion primer, water-based technology, applied in the field of coatings, can solve the problem of limited adhesion, long drying time, coating hardness, flexibility, impact resistance, water resistance, alkali resistance, acid resistance and salt spray resistance. and other problems, to achieve the effects of good salt spray resistance and oil resistance, excellent oil resistance and corrosion resistance, strong adhesion and flexibility

Inactive Publication Date: 2020-06-26

GUANGZHOU JOINTAS CHEM

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, CN109439090A adopts water-based acrylic emulsion and water-based epoxy ester resin emulsion as the coating main body, and prepares a kind of corrosion-resistant and quick-drying environmental protection water-based paint in conjunction with environmental protection solvent, drier and other auxiliary agents, but the adhesion of this water-based paint can only reach level 1 , the adhesion is limited, and the drying time is too long, and the salt spray resistance can only reach 96h; another example is CN105885690A, which uses modified acrylic emulsion, water-based epoxy resin, silica sol, aluminum tripolyphosphate and other additives to prepare anti-corrosion coating, but the flexibility and adhesion of the formed coating are insufficient, and if the modified acrylic emulsion is replaced by an unmodified acrylic emulsion, the hardness, flexibility, impact resistance, water resistance, and alkali resistance of the coating , acid resistance and salt spray resistance will be significantly reduced, and it will be difficult to meet the requirements for corrosion resistance in the field of industrial coatings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

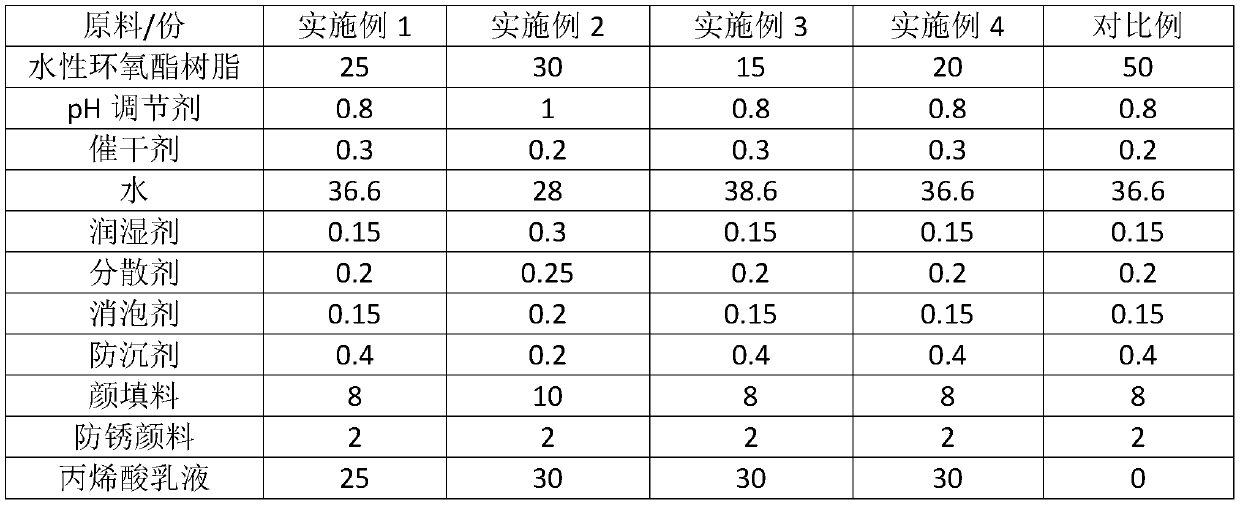

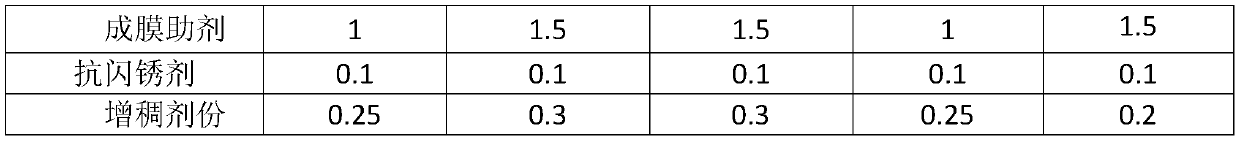

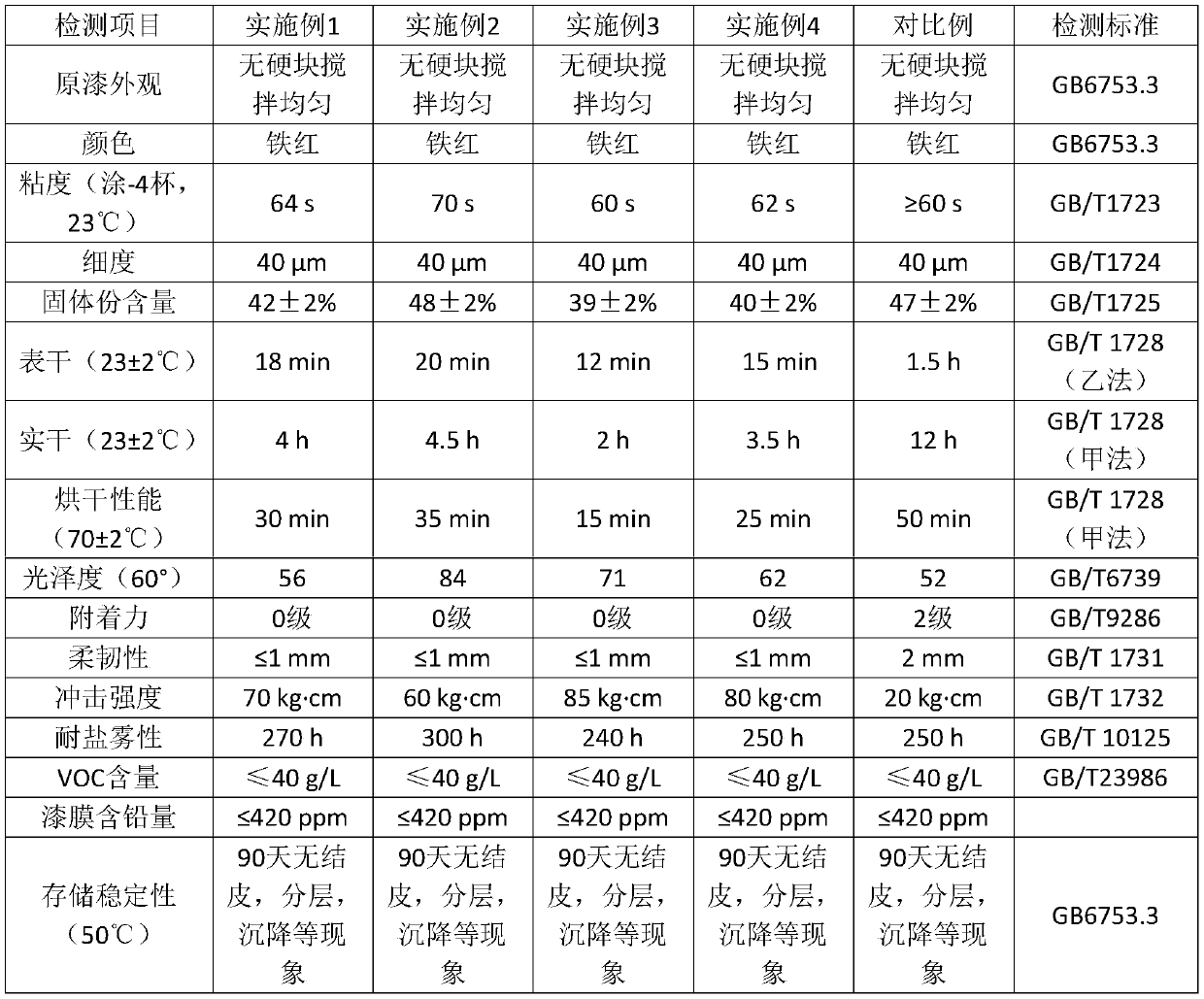

[0047] The technical solution of the present invention is further described below in conjunction with the examples. Other raw materials used in the following examples, unless otherwise specified, are raw materials that can be obtained from conventional commercial channels. Unless otherwise specified, the test methods used are conventional methods or carried out in accordance with the requirements of relevant standards.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a water-based anticorrosive primer and a preparation method thereof. The water-based anticorrosive primer comprises, by weight, 15 to 30 parts of water-based epoxy ester resin,0.5 to 1 part of a pH regulator, 0.2 to 2 parts of a drier, 25 to 45 parts of water, 0.1 to 0.3 part of a wetting agent, 0.15 to 0.25 part of a dispersing agent, 0.1 to 0.25 part of a defoaming agent,0 to 2 parts of an anti-settling agent, 5-20 parts of a pigment filler, 0 to 6 parts of an antirust pigment, 15 to 30 parts of an acrylic emulsion, 1 to 2 parts of a coalescing agent, 0 to 0.2 part of an anti-flash rust agent and 0.1 to 1 part of a thickening agent. The water-based anticorrosive primer is quick in natural drying, the surface drying time does not exceed 20 min, the hard drying time does not exceed 5 h, the adhesive force is high, the VOC content is smaller than or equal to 40 g / L, and the water-based anticorrosive primer is environmentally friendly, safe and excellent in saltspray resistance and oil stain resistance.

Description

technical field [0001] The invention belongs to the technical field of coatings, in particular to a water-based anti-corrosion primer and a preparation method thereof. Background technique [0002] According to statistics, the annual metal loss due to corrosion accounts for about 30% of its annual output in the world. In petroleum, chemical, pesticide and other industrial production, safety accidents caused by corrosion occur frequently, which not only cause huge economic losses, but also lead to the leakage of toxic substances, causing environmental pollution and endangering human life. Therefore, the corrosion problem has been paid more and more attention by countries all over the world. A lot of research has been done on corrosion and protection at home and abroad. By studying the corrosion mechanism and adopting reasonable protection methods to reduce the corrosion rate, the operating cycle of equipment can be greatly improved and significant economic benefits can be ge...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/00C09D133/04C09D5/08C09D5/16C09D7/63C09D7/61

CPCC09D163/00C09D133/04C09D5/08C09D5/1668C09D5/1662C09D5/1687C08L2205/035C08K2003/2272C08L33/04C08L71/02C08L75/04C08K13/04C08K7/26C08K5/06C08K3/22C08K3/28C08L63/00

Inventor 陈淼刘文杰官慧

Owner GUANGZHOU JOINTAS CHEM

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com