Oily antirust primer and application thereof

An anti-rust primer, oil-based technology, used in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve the problems of shortened pipeline life, reduced paint film quality, poor uniformity of anti-rust coatings, etc., and achieve mechanical properties. Good, good oil resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

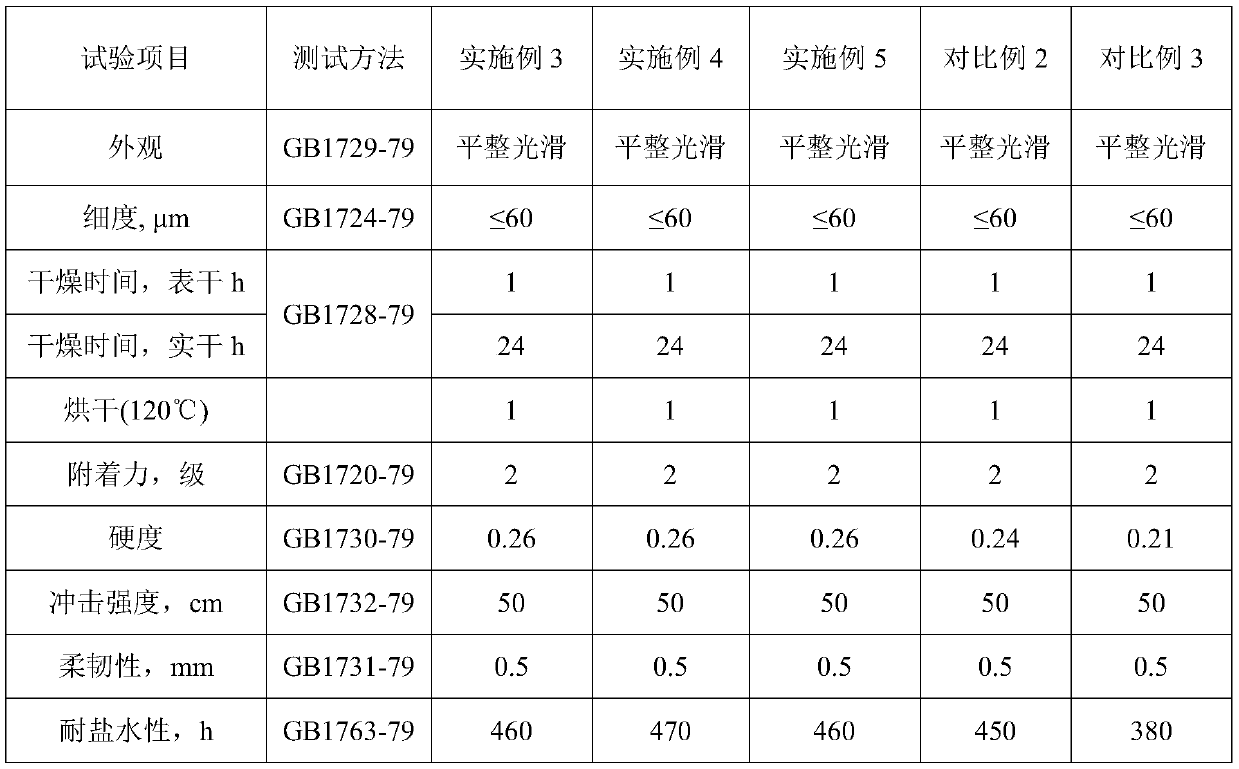

Examples

Embodiment 1

[0032] A kind of alcohol amine modified amorphous silicon dioxide powder, its preparation method comprises the following steps:

[0033] Add 5000 grams of 30wt% sulfuric acid solution in the reaction kettle, then add 20wt% water glass solution to adjust the pH value of the system to 1.5; the time for adding the water glass solution is 30 minutes; after stirring evenly, let it stand for 90 minutes, and the reaction temperature is 50°C ; After standing, adjust the pH value of the mixed solution to 8 with 10% sodium hydroxide solution, and simultaneously heat up to 90° C., and keep it for 30 minutes; adjust the pH value of the system to 3.5 with 10% sulfuric acid solution, and keep it for 20 minutes; The product was filtered and washed until the conductivity was less than 50 μS / cm. Before spray drying, 6-amino-1-hexanol with a weight ratio of 3% of silica was added, the outlet temperature of the spray drying was 110° C., and it was pulverized to 3 μm.

Embodiment 2

[0035] A kind of alcohol amine modified amorphous silicon dioxide powder, its preparation method comprises the following steps:

[0036] Add 5000 grams of 50wt% sulfuric acid solution in the reaction kettle, then add 5wt% water glass solution to adjust the pH value of the system to 4; the time for adding the water glass solution is 90 minutes; after stirring evenly, let it stand for 120 minutes, and the reaction temperature is 60°C ; After standing, adjust the pH value of the mixed solution to 7 with 10% sodium hydroxide solution, and simultaneously heat up to 70° C., and keep it for 10 minutes; adjust the pH value of the system to 4 with 10% sulfuric acid solution, and keep it for 20 minutes; The product is filtered and washed until the conductivity is less than 50 μS / cm. Before spray drying, ethanolamine with a weight ratio of 5% of silica is added, and the outlet temperature of the spray drying is 110° C., and it is pulverized to 4 μm.

Embodiment 3

[0041] An oily antirust primer, made of the following components by weight: 45 parts of epoxy resin, 7 parts of alcohol amine modified amorphous silica powder obtained in Example 1, 0.5 part of 5500 defoamer, 0.6 parts of Digo leveling agent B1484, 0.4 parts of BYK wetting agent Byk3400, 7 parts of ZnO, 8 parts of barite powder, 0.7 parts of fumed silica, 1 part of silane coupling agent kh-560 and 13 parts of diluent, wherein the diluent is Xylene and butyl acetate are composed in a volume ratio of 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com