Anti-static, oil-stain, and corrosion-resistant environmental protection filter material and preparation method thereof

A filter material, oil-resistant technology, applied in filtration and separation, membrane filters, separation methods, etc., can solve the problems of anti-static, weak oil and corrosion resistance, incomplete textile performance, poor filtration effect, etc. Strong environmental protection, excellent anti-static, small gas filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

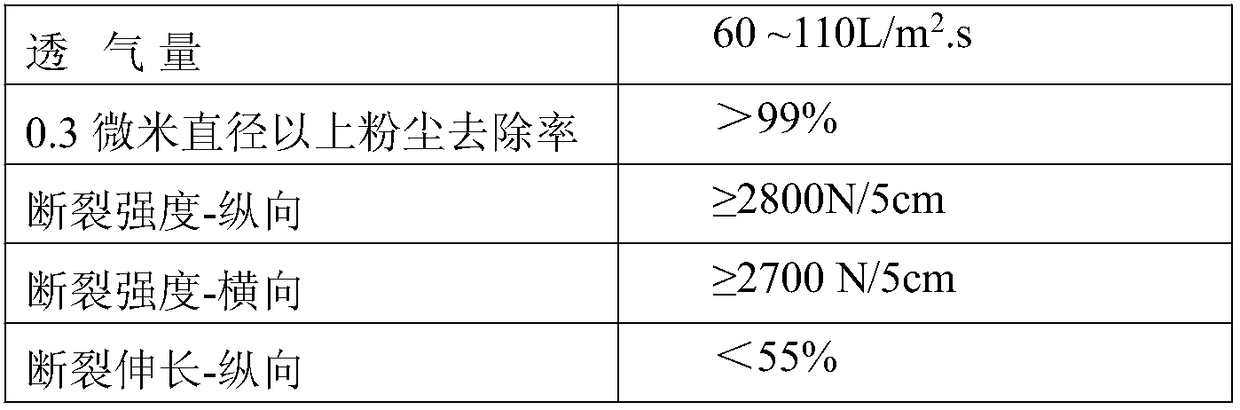

Embodiment 1

[0035] An antistatic, oil-stain, and corrosion-resistant environmental protection filter material, which includes a textile fabric obtained by blending polyphenylene sulfide fibers, polyimide fibers, aromatic polysulfoneamide fibers, and glass fibers. Fluomes needle-punched felt on the upper and lower surfaces of the cloth, chemical film covered on the surface of Flumes needle-punched felt;

[0036] The surface of the aromatic polysulfone amide fiber and glass fiber is impregnated with polyurethane solution;

[0037] The surface of the polyphenylene sulfide fiber and polyimide fiber is impregnated with polytetrafluoroethylene solution;

[0038]The volume ratio of the polyphenylene sulfide fiber, polyimide fiber, aromatic polysulfoneamide fiber and glass fiber is 4:2:6:3.

[0039] The antistatic, oil stain, and corrosion-resistant environmental protection filter material mentioned above has a thickness of 2-8 millimeters and a weight of 700-1200 grams per square meter.

[004...

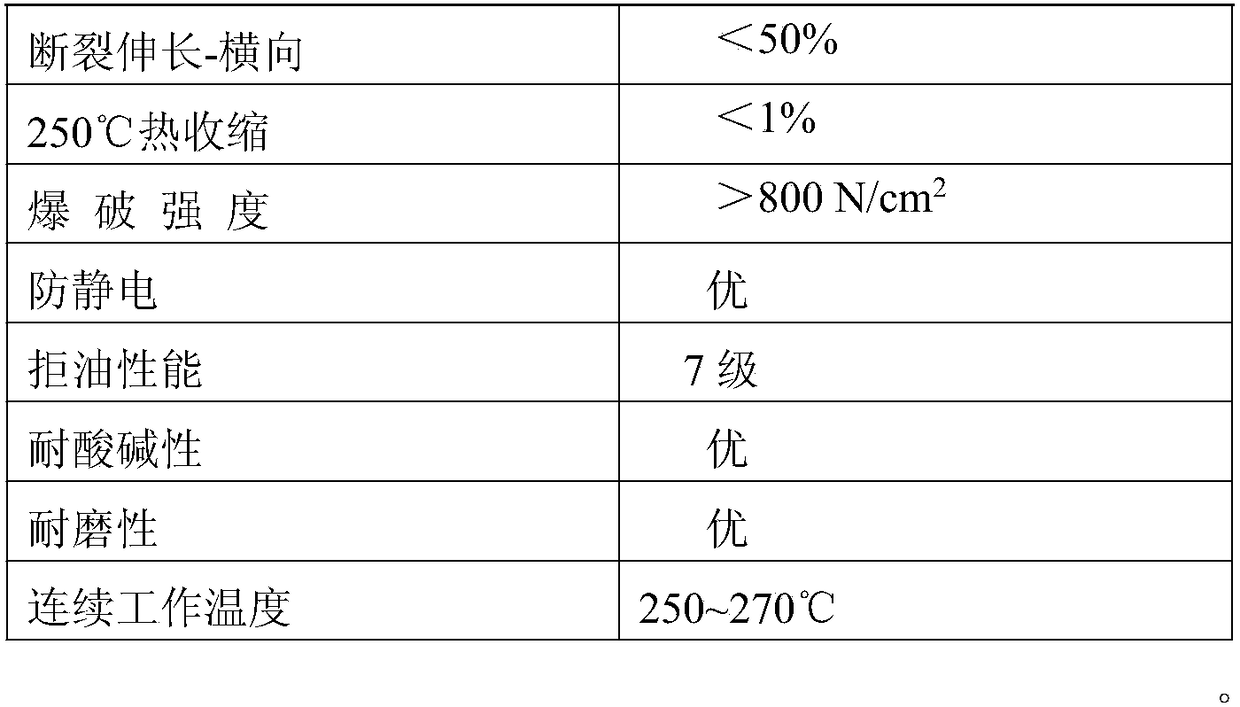

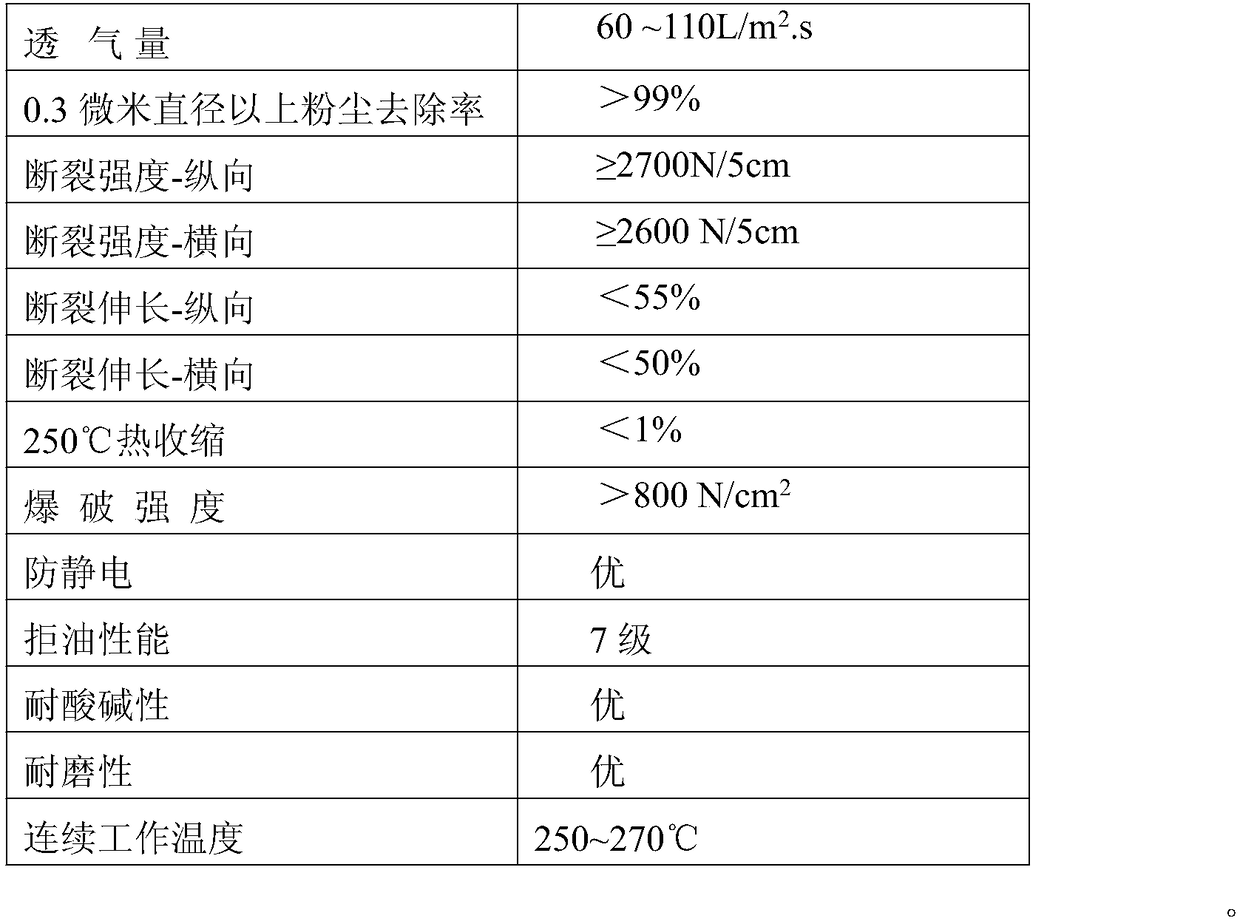

Embodiment 2

[0055] An antistatic, oil-stain, and corrosion-resistant environmentally friendly filter material, which includes a textile fabric obtained by blending nano-polyphenylene sulfide fibers, nano-polyimide fibers, nano-aromatic polysulfone amide fibers and nano-glass fibers, Fluomes needle-punched felt on the upper and lower surfaces of the textile fabric, chemical film covered on the surface of Flumes needle-punched felt;

[0056] The surface of the nano-aromatic polysulfoneamide fiber and the nano-glass fiber is impregnated with a polyurethane solution;

[0057] The surface of the nano-polyphenylene sulfide fiber and the nano-polyimide fiber is treated by dipping in a polytetrafluoroethylene solution;

[0058] The volume ratio of the nano polyphenylene sulfide fiber, nano polyimide fiber, nano aromatic polysulfone amide fiber and nano glass fiber is 1:2:3:1.

[0059] The antistatic, oil stain, and corrosion-resistant environmental protection filter material described above has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com