A kind of compound for preparing ceramic material and its preparation method and ceramic capacitor

A technology of ceramic capacitors and ceramic materials, applied in capacitors, fixed capacitors, multilayer capacitors, etc., can solve the problems of limitation, high residual polarization, low breakdown field strength, etc. The effect of ordering and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

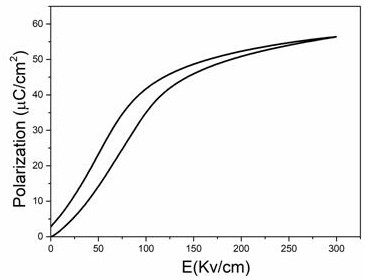

Image

Examples

preparation example Construction

[0039] The present invention is a method for preparing the preparation of a ceramic composite material, comprising the steps of:

[0040] The dried powdered Na 2 CO 3 , SrCO 3 , MgO, Nb 2 O 5 , BI 2 O 3 And TiO 2 Stoichiometric ratio formula were weighed, mixed, milled, calcined, and drying.

[0041] To ensure powdered Na 2 CO 3 , SrCO 3 , MgO, Nb 2 O 5 , BI 2 O 3 And TiO 2 Dry, weighing error does not occur, affecting the performance of the ceramic material, prior to taking the said feedstock at 180 ~ 300 ℃ drying process 8h.

[0042] Using ball milling is yttrium-stabilized zirconia balls, in which the composite mass, yttrium-stabilized zirconia balls and the solvent may be 1: 1: 2, preferably, the ethyl alcohol as a solvent, butanone, preferred is ethanol. The use of ethanol as a solvent low cost, little harm to the human body.

[0043] An embodiment of the present invention, the calcining temperature is 850 ~ 900 ℃, burn time of 3h. At 850 ~ 900 ℃ of the complex of the present...

Embodiment 1

[0065] Method for preparing ceramic capacitor, the following steps:

[0066] A) The analytically pure anhydrous Na 2 CO 3 , SrCO 3 , MgO, Nb 2 O 5 , BI 2 O 3 And TiO 2 After drying at 180 ~ 300 ℃ treated 8h, the composite according to the formula: 0.69Bi 0.5 Na 0.5 TiO 3 -0.3Sr 0.7 Bi 0.2 TiO 3 -0.01Bi (Mg 2 / 3 NB 1 / 3 ) O 3 The stoichiometric ratio of the respective Weigh raw materials are mixed to obtain a mixture;

[0067] B) the mixture obtained in step A in absolute ethanol to yttrium-stabilized zirconia balls as milling media planetary 24h, mixture, yttrium-stabilized zirconia balls, ethanol mass ratio 1: 1: 2, after which the mixed abrasive removed 80 drying ℃ for 24h;

[0068] After C) The mixture obtained in Step B in air at 900 deg.] C prefired 3h, grinding, sieving second ball milling, the mixed powder, yttrium-stabilized zirconia balls, ethanol mass ratio 1: 1: 2 slurry removed 80 drying ℃ for 24h;

[0069] D) obtained in Step C prefired baking powder was sieved, added m...

Embodiment 2

[0075] Complex is of the general formula: 0.68Bi 0.5 Na 0.5 TiO 3 -0.3Sr 0.7 Bi 0.2 TiO 3 -0.02Bi (Mg 2 / 3 NB 1 / 3 ) O 3

[0076] Prepared as in Example 1, except that the calcining temperature 850 ℃, the sintering temperature 1200 ℃.

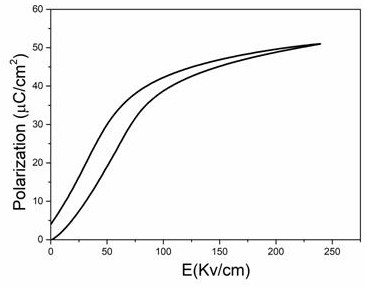

[0077] Properties such as figure 2 , The energy density of 2.5J / cm 3 Energy storage efficiency of 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com